Candy-producing furnace end capable of accelerating humidifying and cotton candy machine with same

A burner, fast technology, used in confectionery, confectionery industry, food science and other directions, can solve the problem of low humidity of sugar stove head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

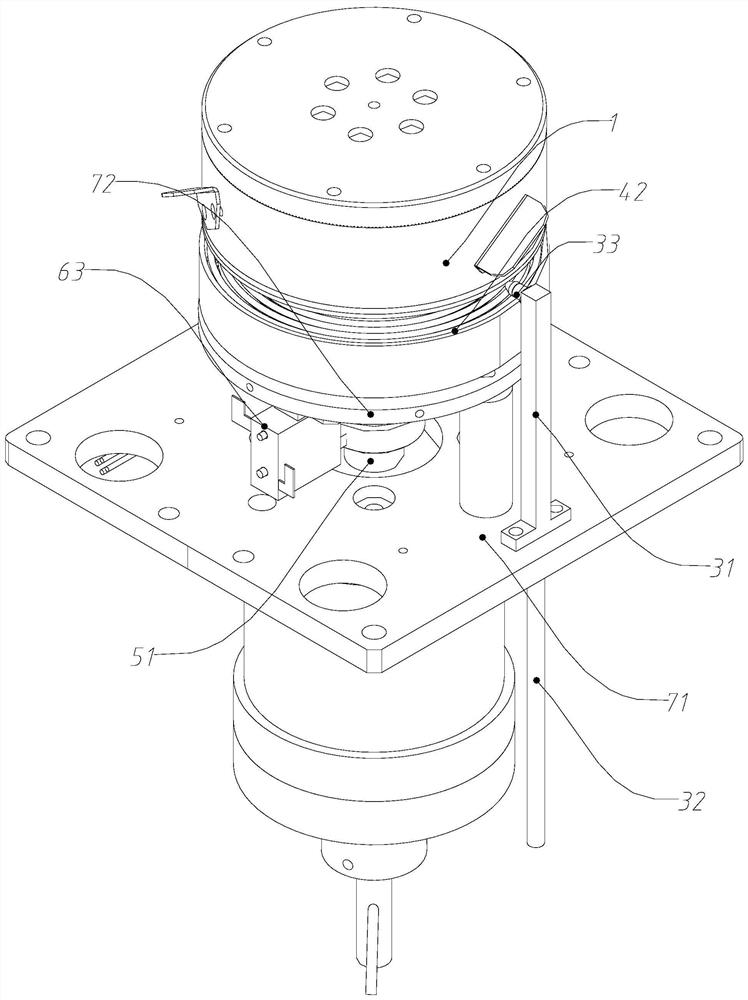

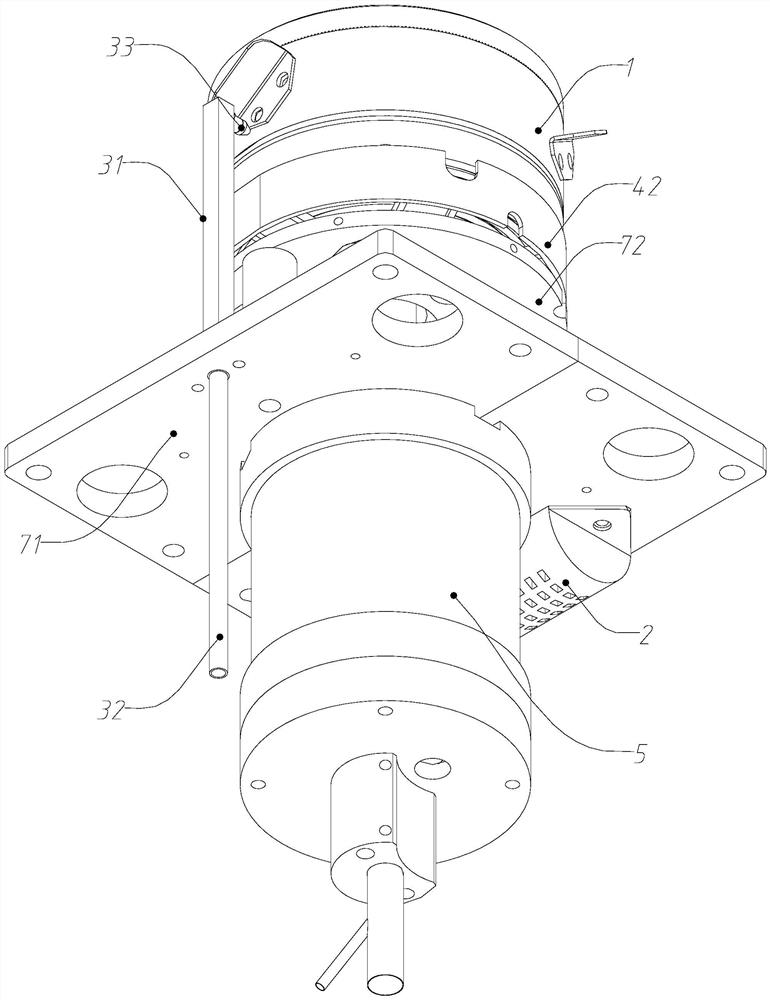

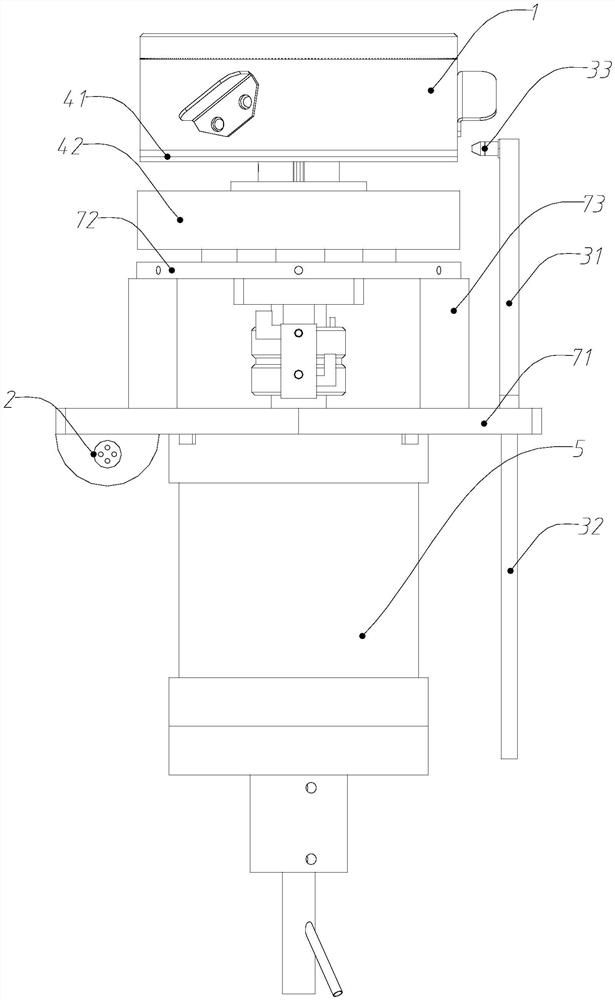

[0050] As a further technical solution, such as Figure 6 As shown, the scheme is to further increase the efficiency of the air humidity in the vicinity of the glucose furnace head body 1, uniformly disposed in the outer side of the sugar-head body 1, and several humidification means are electrically connected to the controller and are installed. On the base; several spray heads 33 facing the sidewalls of the glucose furnace head body 1.

[0051]Specifically, the water sprup 31 of the humidification device is coupled to the fixing plate 71, and several sprinkler 33 are adjacent to the side wall of the glucose head body 1, and to ensure the spray head 33 injection. The fine water column can quickly obtain sufficient heat from the sugar-head body 1, and by uniformly dispose of several humidification devices near the outer side of the glucose head body 1, not only the air humidity efficiency is increased by evaporating the water column in the direction. High, and more evenly evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com