Steering engine torque compensation mechanism capable of reducing control surface torque

A compensation mechanism and torque technology, which is applied in the field of steering gear mechanism design, can solve the problems of lack of special steering gear, etc., and achieve the effect of reducing the torque output demand of the steering gear, reducing the output demand, and expanding the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

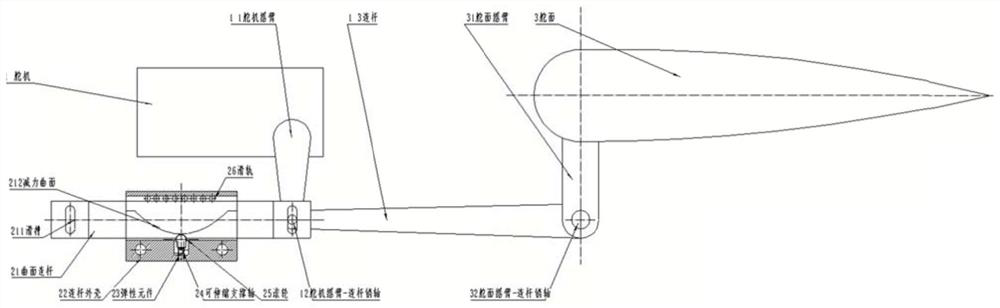

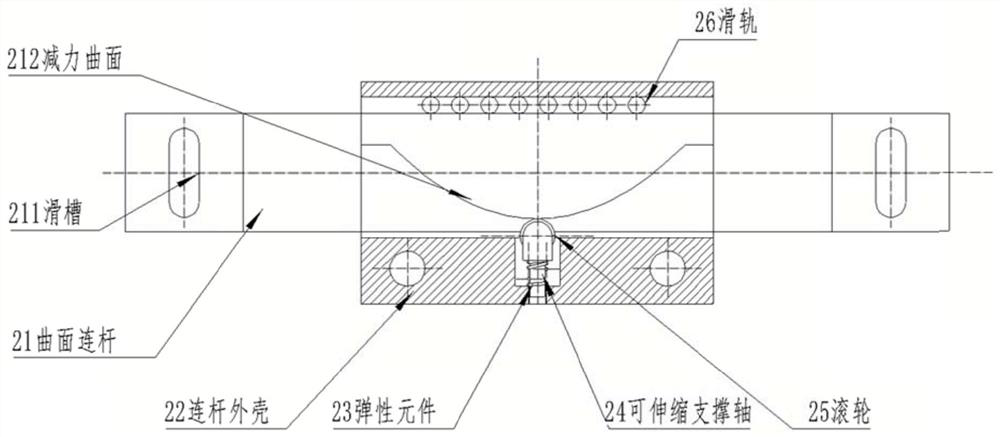

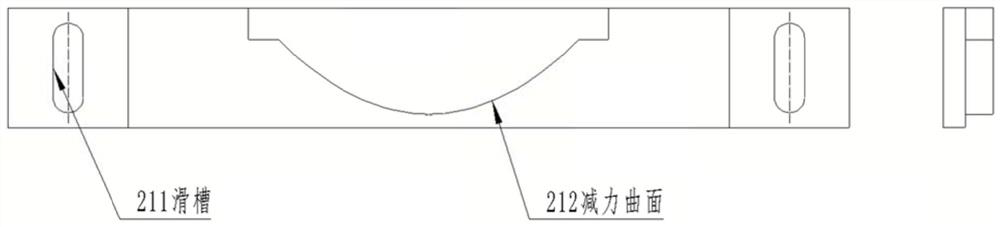

[0019] A steering gear torque compensation mechanism that reduces the torque of the rudder surface, such as figure 1 As shown, they are respectively connected to the steering gear and the steering surface, and the torque of the steering surface is compensated by using the force generated by the elastic element to drive the roller to press the curved surface connecting rod tightly, which reduces the torque output demand of the steering gear and expands the selection range of the steering gear. It solves the problems of too large design types, difficult operation, and low reliability of conventional steering gears, mainly including chute holes, curved surface connecting rods, connecting rod shells, force-reducing curved surfaces, elastic elements, telescopic support shafts, rollers, slide rails, in:

[0020] Chute hole-211, force reduction curved surface-212, curved surface connecting rod-21, connecting rod shell-22, elastic element-23, telescopic support shaft-24, roller-25, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com