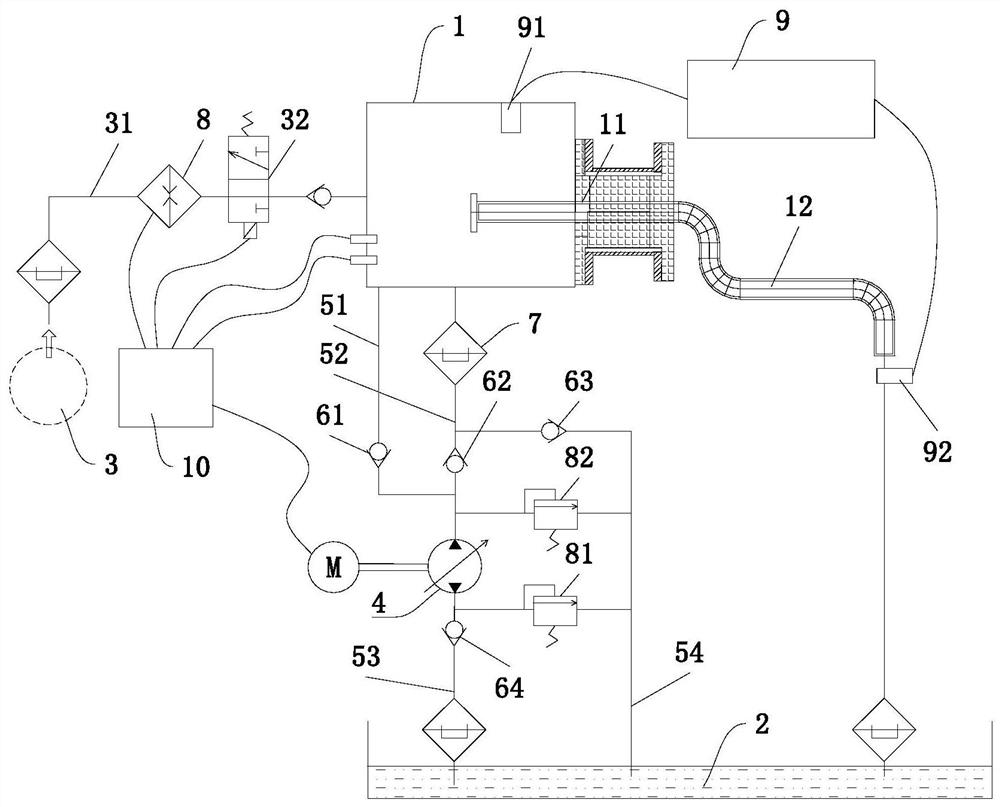

A kind of pipeline cleaning device and cleaning method

A technology for cleaning and cleaning pipelines, applied in cleaning methods and utensils, separation methods, measuring devices, etc., can solve the damage of fluid pipeline interface, difficult to adapt to a variety of different pipelines to be cleaned, difficult to adapt to large Efficient and fast cleaning of batch pipelines to achieve the effect of improving cleaning efficiency and avoiding chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0086] As an alternative embodiment of this embodiment, a negative pressure generating device capable of generating negative pressure energy inside the current collecting chamber 1 can also be selectively arranged on the current collecting chamber 1, so that all the The fluid cleaning working medium is backflowed in the pipeline being cleaned. The negative pressure generating device can be selectively set as a pressure relief component or device with a pressure relief function, for example, a piston cylinder with a suction function, and the like. In this embodiment, the liquid pump 4 can be set as a piston cylinder with a suction function, which can effectively reduce the manufacturing cost.

[0087] As a preferred embodiment of the present application, an air flow control switch 32 is further selectively arranged on the gas channel 31 , and the air flow control switch 32 controls the connection between the gas working medium source 3 and the collecting cavity 1 . The airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com