A plasma etching method for large-diameter optical components

An optical element and plasma technology, applied in electrical elements, circuits, discharge tubes, etc., can solve the problems of inability to process medium and large-diameter optical elements, prolong the processing cycle, increase time and economic cost, and solve the surface residual stress and Subsurface damage, increased control dimension and control margin, and the effect of high-efficiency etch removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

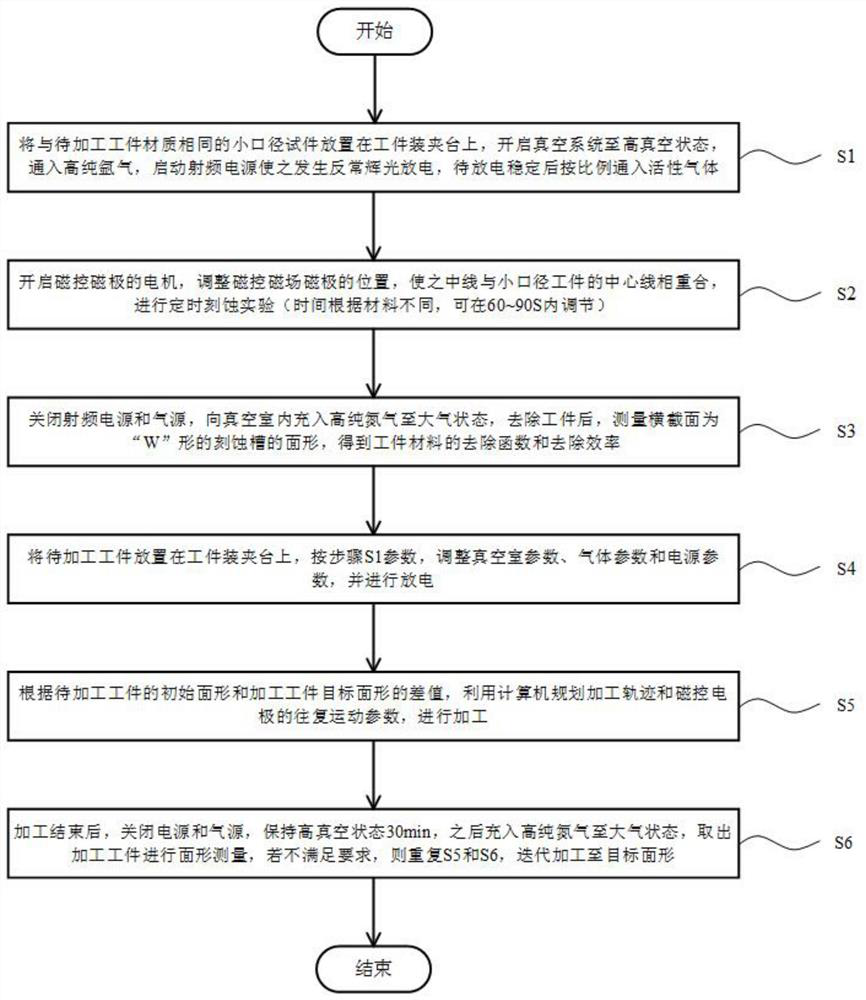

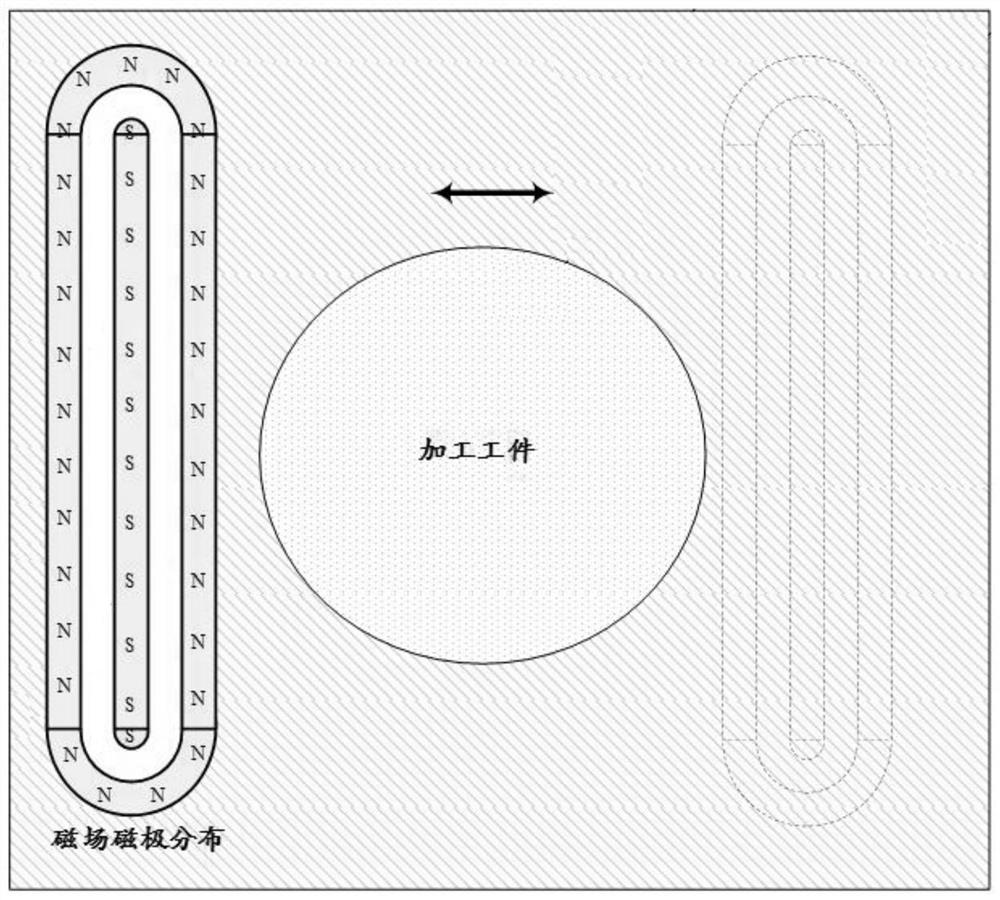

[0030] see figure 1 , a kind of plasma etching method provided by the invention comprises the following steps:

[0031] Step 1: Place the roughly ground fused silica optical specimen on the workpiece clamping table in the vacuum chamber, turn on the vacuum pump set connected to the vacuum chamber, and pump the vacuum chamber to 8.0×10 -4 Pa, introduce high-purity argon gas into the processing area of the optical element of the vacuum chamber through the gas distributor (the gas distributor is located directly above the optical element, keep the centerlines of the two coincident), control the working vacuum of the vacuum chamber to 1Pa, and turn on the cooling water pair. The component clamping table is cooled, and the radio frequency power supply is turned on to discharge. After the discharge is stable, carbon tetrafluoride (CF 4 ) and oxygen (O 2 ), the working vacuum is 1Pa, the mass flow ratio of argon and carbon tetrafluoride is controlled at 1:1, and the oxygen ratio ...

Embodiment 2

[0046] The processing object is silicon carbide components, and the active gases introduced are sulfur hexafluoride and oxygen, and its mass flow ratio to argon can be formulated as Ar:SF 6 :O 2 It is 5:5:1, and other steps are the same as in Example 1.

Embodiment 3

[0048] The processing element is made of metal aluminum. In step 1, argon gas is introduced, and the working vacuum can be controlled at 0.6~1Pa, which is 1Pa in this embodiment. The etching time in step 2 is 60S, and other steps are the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com