Plate overturning device for wood floor processing

A technology for wooden floors and flaps, applied in wood processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and manpower consumption, and achieve the effects of reducing production costs, high applicability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

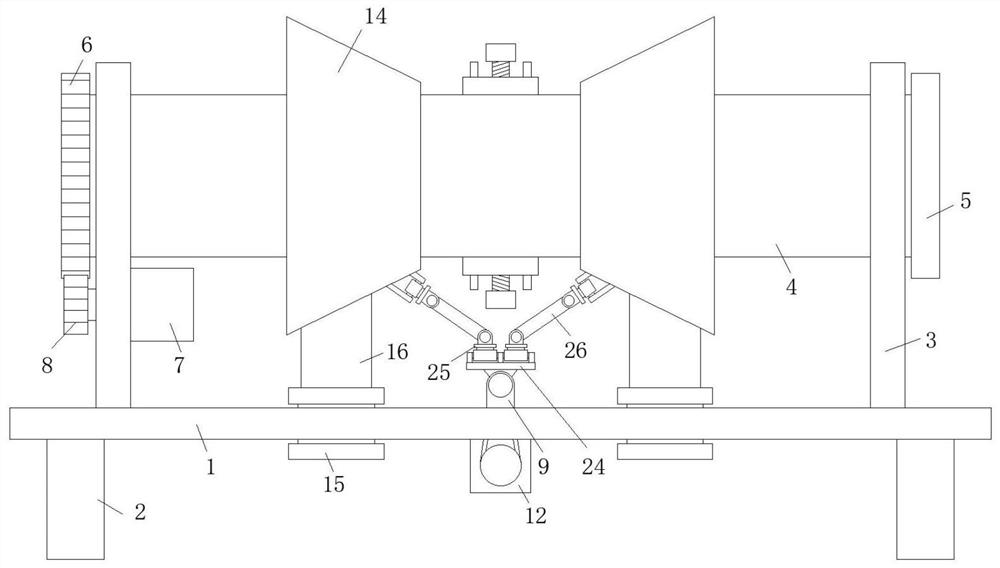

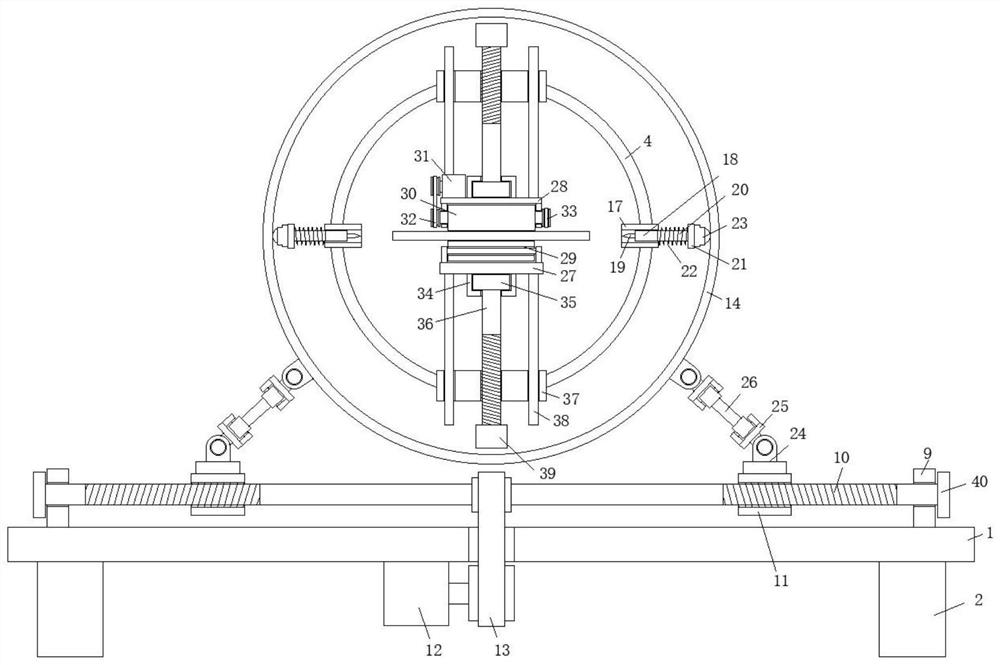

[0026] refer to Figure 1-3 , a kind of turnover device for wood floor processing, comprising workbench 1, both sides of the top of workbench 1 are fixedly connected with riser 3, and the board body of riser 3 is provided with horizontal round hole 1, and the two riser 3 The material transfer cylinder 4 is installed in rotation, and the two ends of the material transfer cylinder 4 respectively pass through the horizontal hole 1, and the outer side of one end of the material transfer cylinder 4 is fixedly connected with the limit ring 5, and the outer side of the other end is fixedly connected with the active ring 5. Gear 8, one side of the vertical plate 3 is fixedly equipped with a motor 7 by bolts, the output shaft of the motor 7 is fixedly connected with a driving gear 8, and the driving gear 8 is meshed with the driven gear ring 6. The vertical plate 9 is fixedly installed on the side, and the rotating rod 10 is installed in rotation between the vertical plates 9. The rota...

Embodiment 2

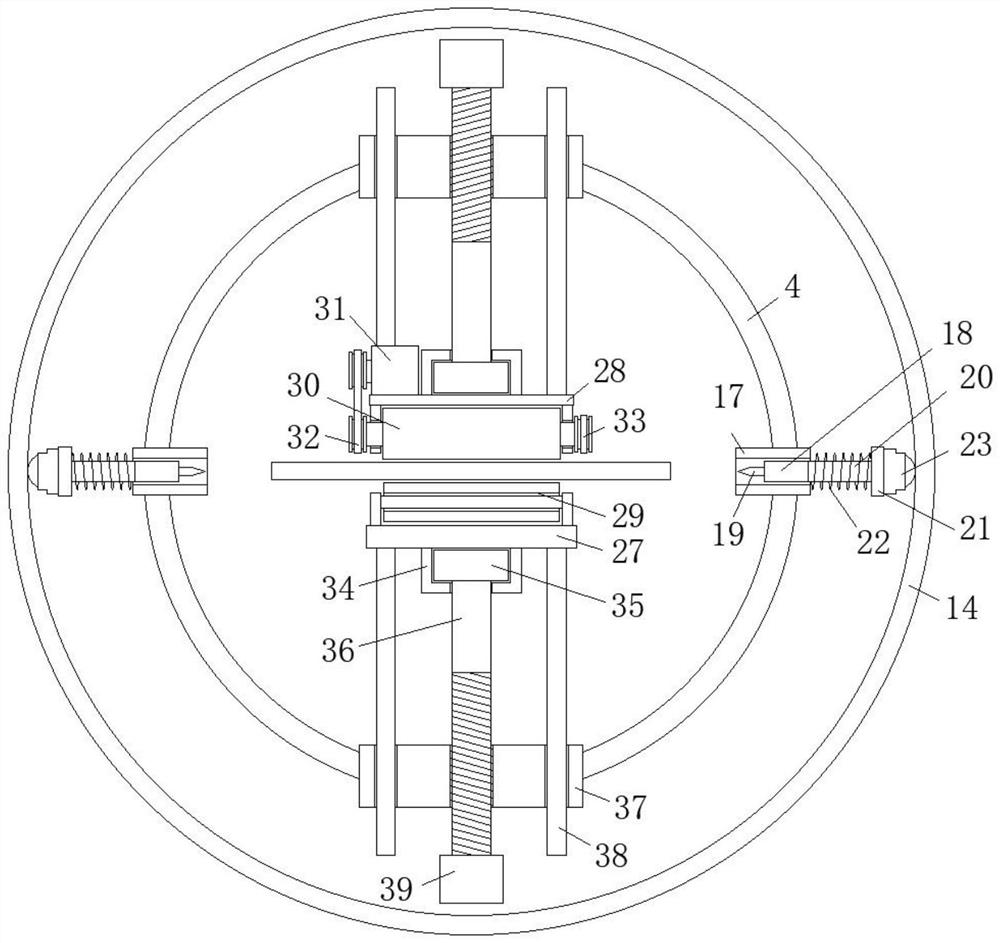

[0030] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the rotating sleeves 34 are respectively fixedly connected to the sides of the horizontal plate 1 27 and the horizontal plate 2 28 away from each other, and the top and bottom of the cylinder 4 are both Be provided with installation hole ratio and fixedly install lath 37 respectively, the plate body of lath 37 is provided with slide hole and threaded hole, and one end of slide rod 38 passes in the slide hole, and the other end is connected with horizontal plate one 27 and horizontal plate two 28 respectively. Fixedly connected, one end of the threaded shaft 36 is threaded through the threaded hole, and the other end of the threaded shaft 36 is coaxially fixedly connected with the circular plate 35 .

[0031] In this embodiment, the lengths of the first horizontal plate 27 and the second horizontal plate 28 are equal to the length of the transfer cylinder 4. After the flippin...

Embodiment 3

[0033] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the threaded shaft 36 is fixedly connected with a knob 39 , and the outer side of the knob 39 is provided with anti-slip grooves.

[0034] In this embodiment, the setting of the knob 39 greatly facilitates the twisting of the threaded shaft 36 by people, which is labor-saving and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com