Automatic assembly equipment for rotor insulating paper

一种自动装配、绝缘纸的技术,应用在敷设固体绝缘等方向,能够解决绝缘纸安装过程繁琐、绝缘纸易放置不到位等问题,达到工序质量稳定可靠、减少人工用工成本、提升工作效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

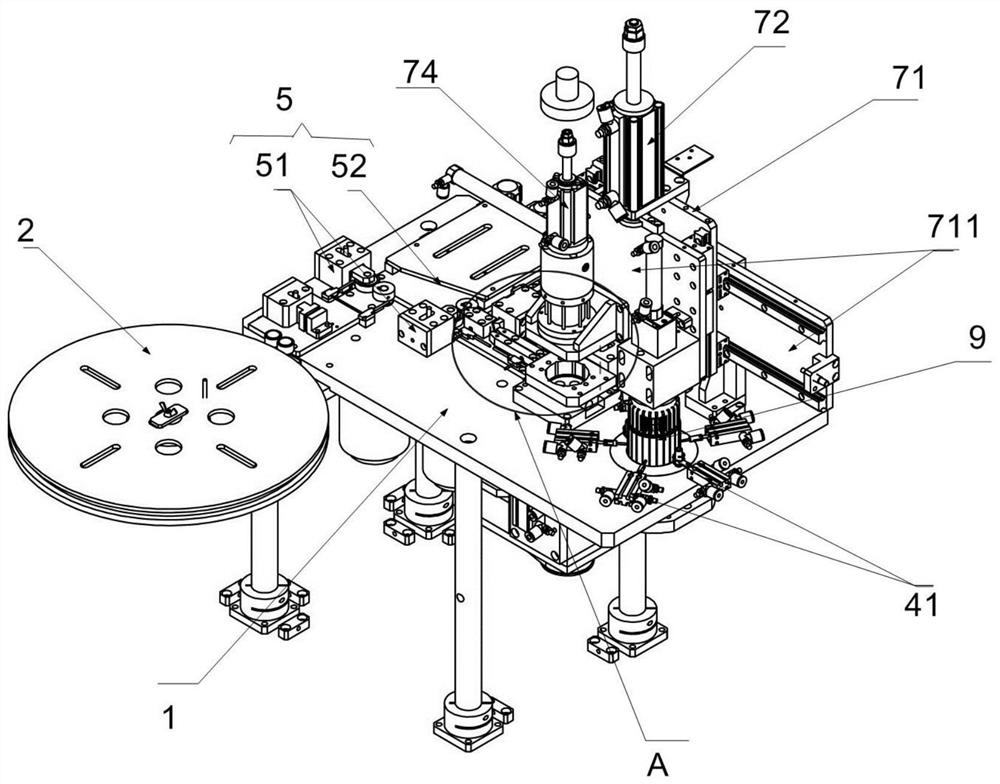

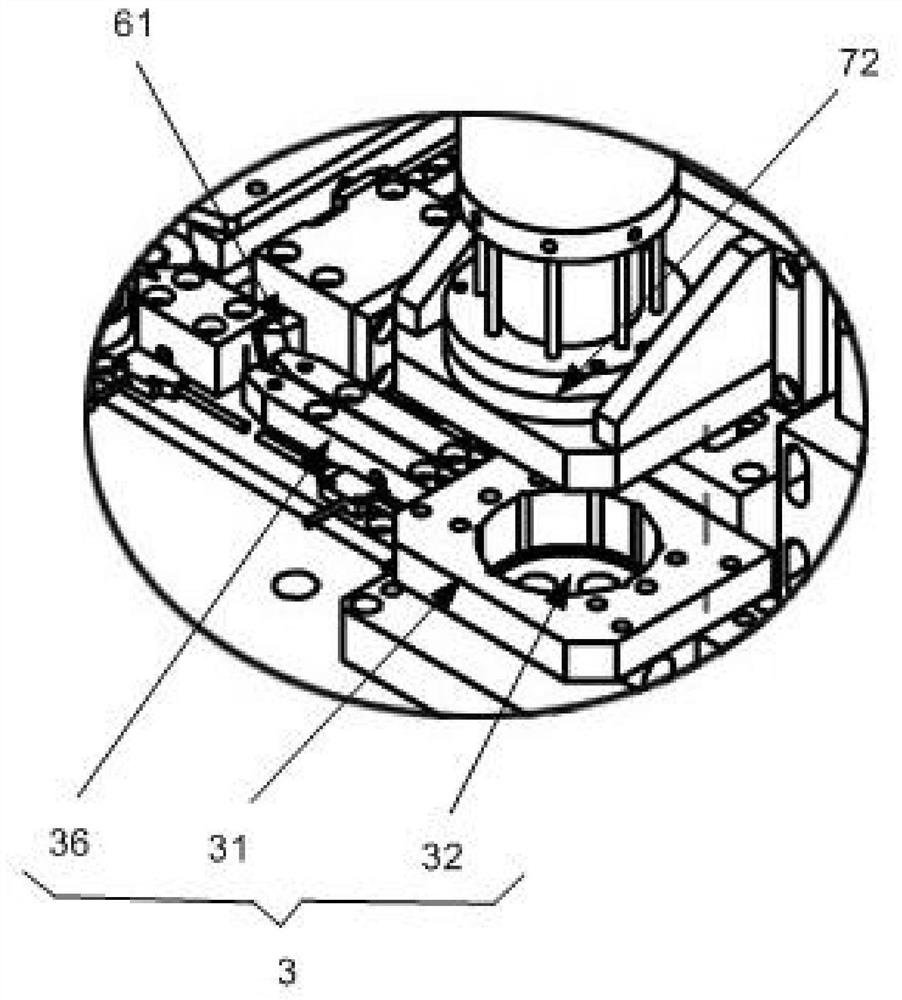

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0032] It should be noted that, in the process of assembling insulating paper for the rotor assembly at present, a layer of insulating paper is generally manually wound and placed at the required position between the two layers of elements at the reversing end of the rotor. When a single layer of insulating paper is used for insulation, the insulating paper is easily pierced by the burrs generated when the components are formed, which can still cause the inner and outer components to overlap and short circuit; if two layers of insulating paper are manually placed, due to the difficulty of manual assembly, the shape of the insulating paper It is easy to dislocate and skew, and there are multiple layers of insulating paper superimposed loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com