Internal corner connecting piece and mounting method thereof

An installation method and a technology of connecting parts, which are applied in the direction of connecting components, thin-plate connections, mechanical equipment, etc., can solve the problems of hidden vibration, high transportation cost, and uneven gaps in the inner corner of the drop, so as to improve the appearance effect and optimize the connection Structure, the effect of solving the seam problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

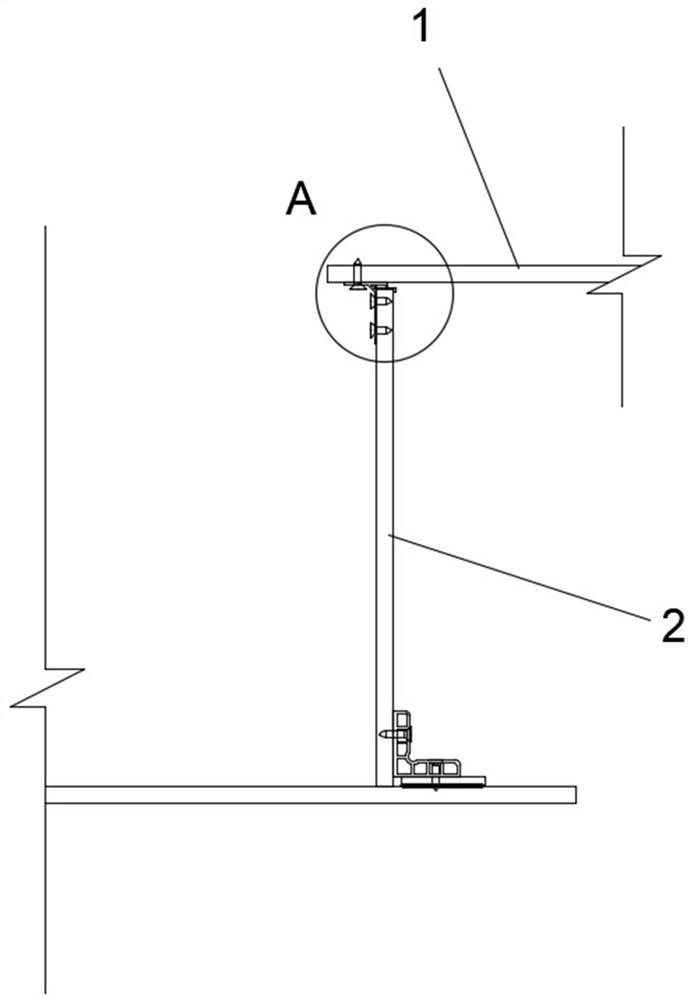

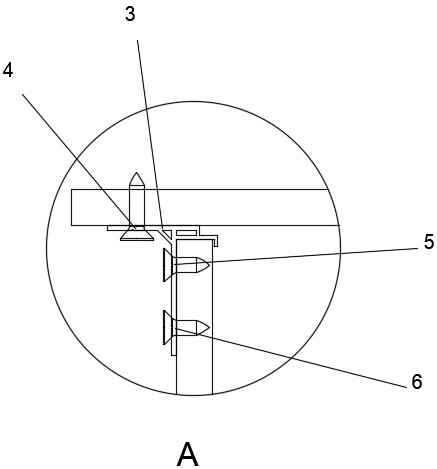

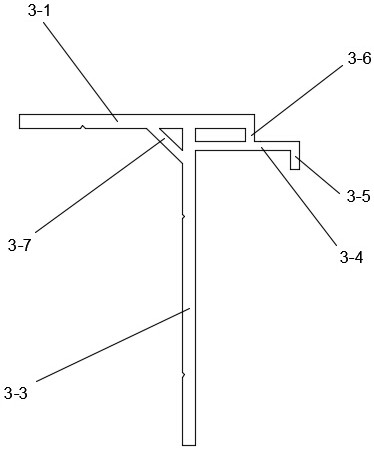

[0028] Such as Figure 1-5 As shown, a female corner connector includes a body 3, the body 3 is composed of a connected supporting part 3-1 and a connecting part 3-2, the connecting part 3-2 is connected below the supporting part 3-1, and the supporting part 3 -1 is a horizontal structure, the connecting part 3-2 is a vertical structure, and the supporting part 3-1 and the connecting part 3-2 are vertically arranged.

[0029] The main body 3 is a metal structure, the supporting part 3-1 and the connecting part 3-2 are integrally formed, the supporting part 3-1 is connected with the top plate 1, and the connecting part 3-2 is connected with the vertical plate 2. To realize the connection between the top plate 1 and the vertical plate 2, the length of the body 3 is set according to the actual length of the top plate 1 and the vertical plate 2.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com