Automobile door lock installation structure

An installation structure and a technology for automobile door locks, which are applied in the field of automobile parts installation, can solve the problems of simple rebound structure, inconvenient connection between the lock tongue and the base, lack of linkage mechanism, etc., and achieve the effect of increasing the stability of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

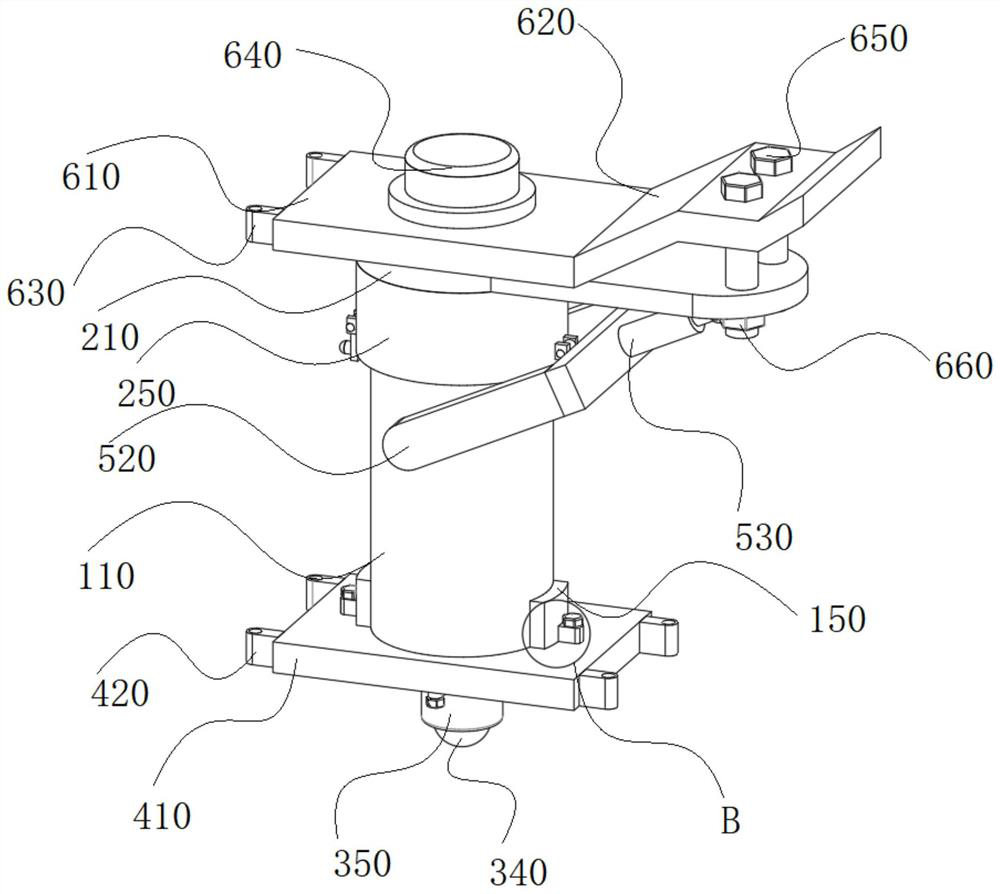

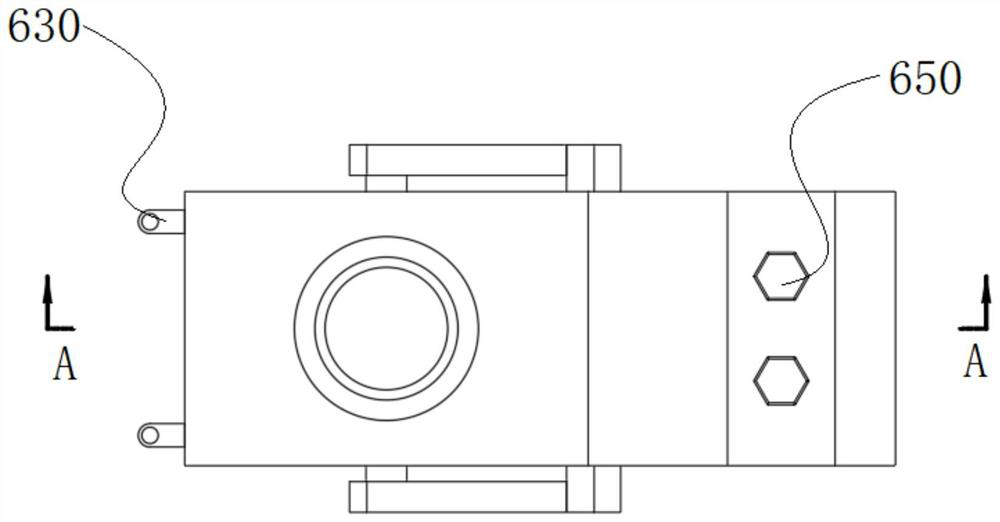

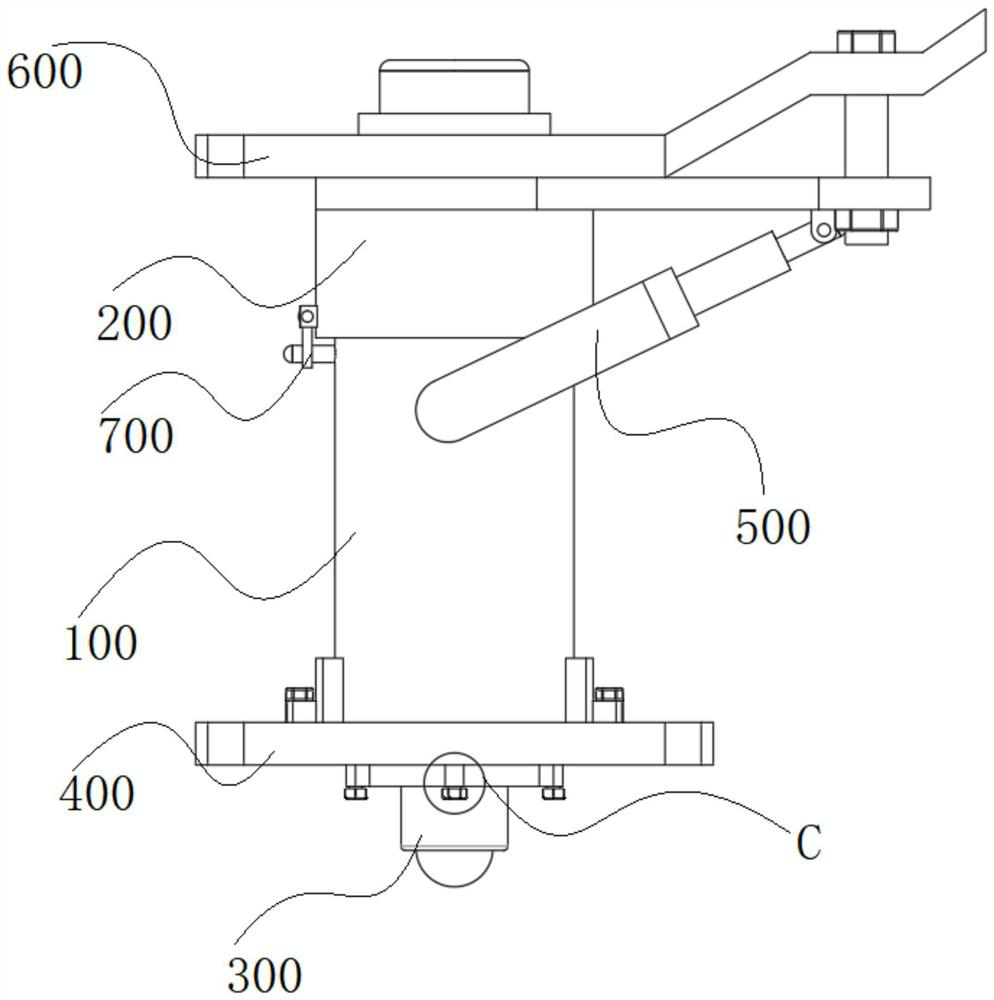

[0035] refer to figure 1 —10, the present invention is a car door lock installation structure, including a deadbolt 100, a base 200, a push mechanism 300, a first installation mechanism 400, a linkage mechanism 500, a second installation mechanism 600 and a locking mechanism 700, the deadbolt 100 includes an outer clamping column 110, an inner clamping column 120, and a fixed block 150. The base 200 includes a bottom plate 210, a mounting column 220, a long column 230, and a long tube 250. Both the outer clamping column 110 and the inner clamping column 120 are hollow structures, and the long column The sides of the 230th circle slide with the inner side of the inner clamping column 120. The pressing mechanism 300 includes a piston plate 330 and a fixed clamping column 350. The fixed clamping column 350 is a hollow structure, and the side of the piston plate 330 slides with the inner circumference of the outer clamping column 110. Cooperate, the lower surface of the inner clam...

Embodiment 2

[0044] The working principle of the present invention is as follows: four sets of slide plates 130 are symmetrically arranged on the outer peripheral side of the inner clamping column 120, and the formed slots just play a limiting role on the push block 240, preventing the push block 240 from compressing the return spring 140. Due to the lack of limit, there is a problem of difficulty in compression. A through hole is provided inside the inner clamping column 120. During the travel process of the push block 240 compressing the return spring 140, the long column 230 slides and fits with the through hole, which is also conducive to compression. Stable, the rotation and cooperation between the rotating ring 730 and the fixed card seat 710 can easily change the locking angle of the locking plate 740, mainly according to the linkage mechanism 500 to adjust the locking angle. Compared with the traditional locking structure, the locking plate The way of sliding connection between 740 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com