Adjustable gravel crushing and screening machine

A screening machine and regulating technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems such as the filter screen can not work, the stones are easy to block, and there are potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

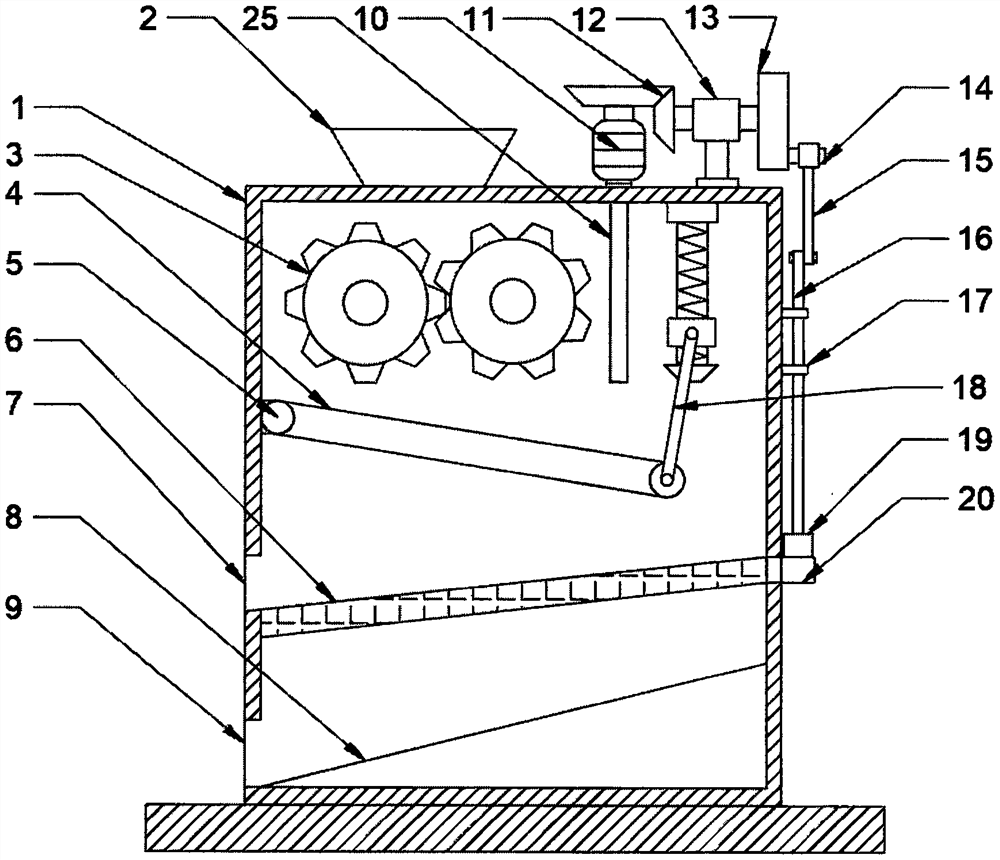

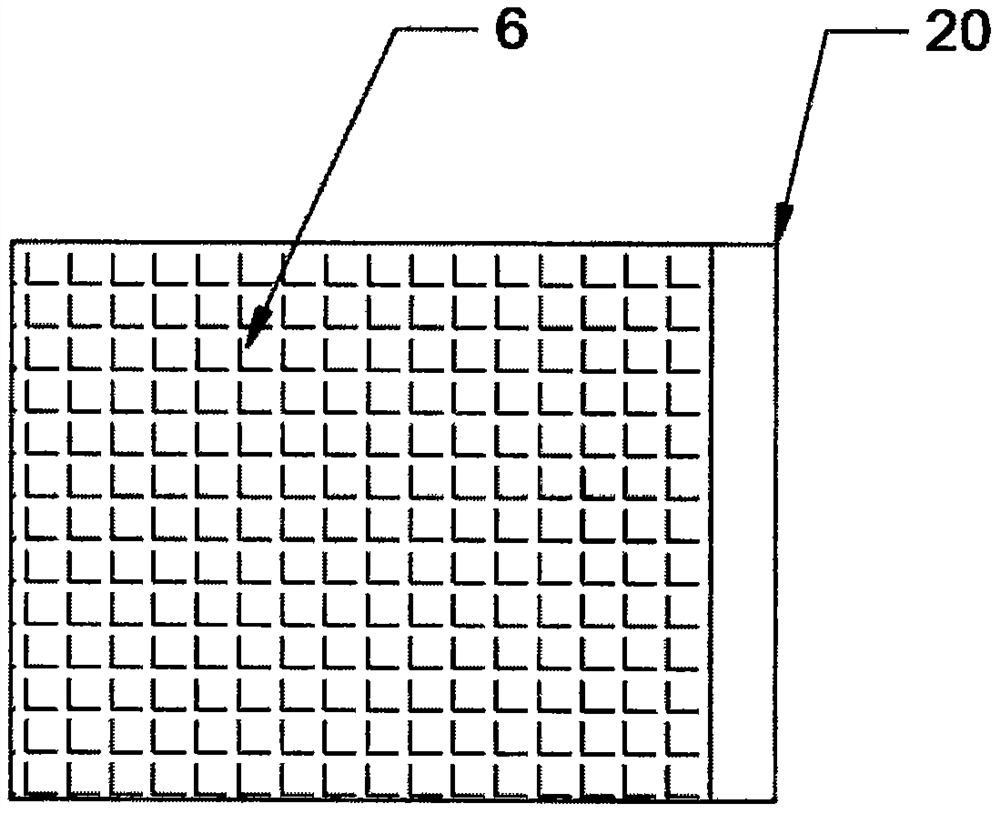

[0020] see Figure 1~3 , in Embodiment 1 of the present invention, an adjustable sandstone crushing and screening machine includes a body 1, and the body 1 includes a crushing part and a screening part, and the crushing part includes two crushing rollers 3, and the crushing roller 3 It is arranged on the upper part of the machine body 1, and the crushing roller 3 is used to crush gravel, and the movable plate 4 placed obliquely is arranged below the crushing roller 3, and the movable plate 4 is used to make the crushed stones slide down, and the movable plate 4 The left end is movably arranged on the movable shaft 5, and the movable plate 4 can be rotated by the movable shaft 5 to adjust the inclination, and the movable shaft 5 is fixed on the left side of the body 1, and the right side of the movable plate 4 is connected with an adjustment mechanism, To drive the movable plate 4 to rotate, a filter screen 6 is arranged directly below the movable plate 4, and the filter screen...

Embodiment 2

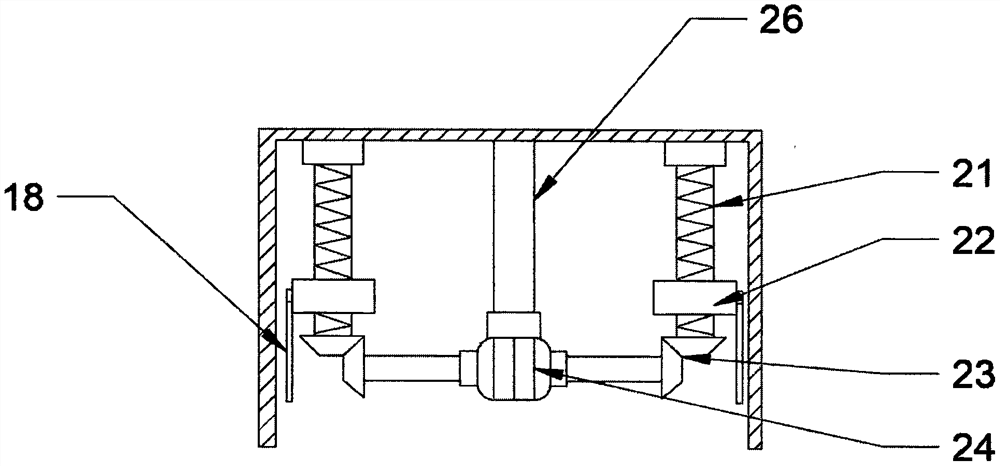

[0023] see Figure 1~3 The high end of the filter screen 6 is connected with a vibration block 20, which is used to drive the filter screen 6 to vibrate. Fast 19, knocking fast 19 is used for knocking vibration block 20.

[0024] Further, a movable rod 16 is connected above the knocking fast 19, and the movable rod 16 is used to drive the knocking fast 19 to move up and down. It is used to drive the movable rod 16 to move up and down. The other end of the a transmission rod 15 is connected to the support 14 in rotation. The support 14 is used to drive the a transmission rod 15 to rotate. The support 14 is arranged on the runner 13, and the runner 13 Used to drive the pillar 14 to rotate, the runner 13 is fixed on the top outside of the body 1 through the sleeve 12, and the top outside of the body 1 is also provided with a deceleration motor 10, and the deceleration motor 10 passes through a bevel gear set 11 Connected with the running wheel 13 in transmission, the reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com