Double-station automatic plate sending machine

It is a technology of plate-making machine and double-station, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc. It can solve the problems of high plate loss rate, inability to accurately locate, and rough transportation mode, so as to achieve cost saving and easy operation. Accurate, stable and efficient transportation of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

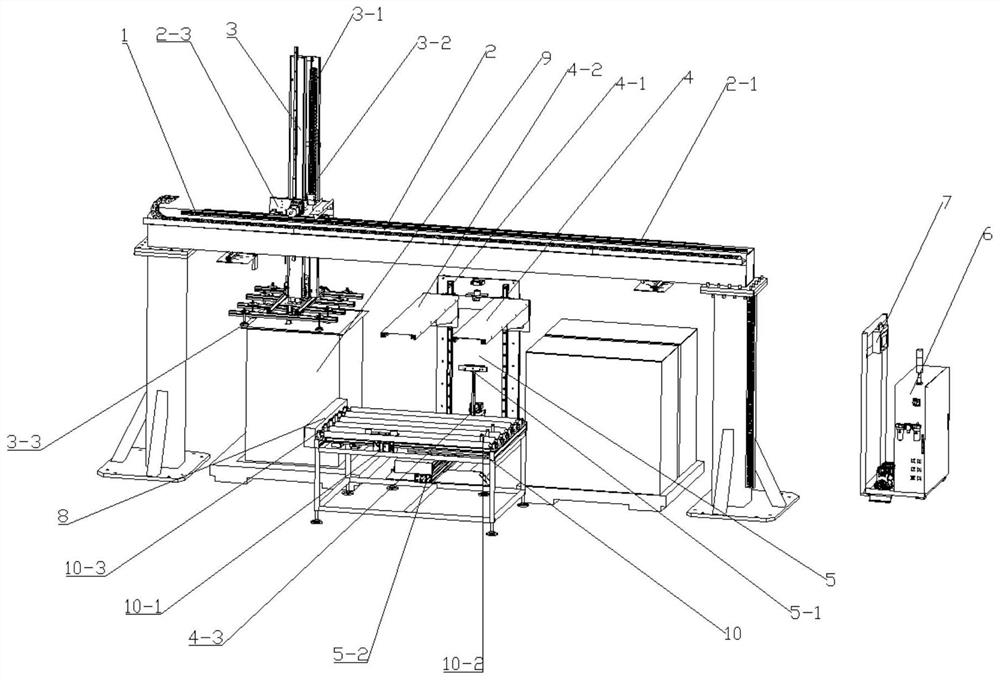

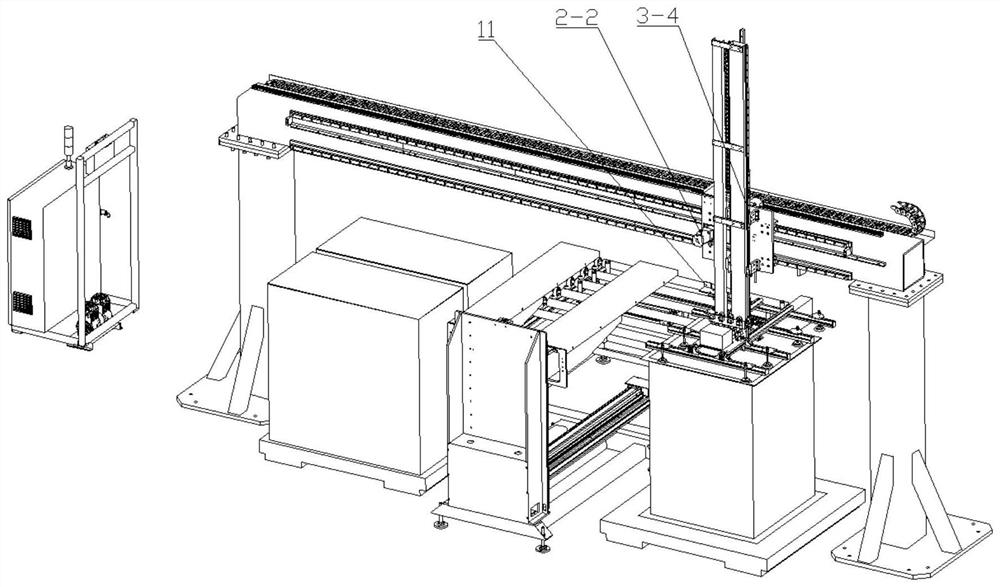

[0026] The present invention provides a dual-station automatic board-forming machine, which includes a truss 1 and a control cabinet 6. The truss 1 is provided with a left and right movement module 2 for taking materials and a movement module 3 for taking materials up and down. The module 2 can drive the reclaimer to move up and down the module 3 to move on the truss 1. There are two product feeding platforms 9 and a material pushing structure under the truss 1, and the two product feeding platforms 9 are symmetrically arranged on the Both sides of the aforementioned material pushing structure, the described material pushing stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com