Tail door structure and vehicle

A tailgate and automobile technology, applied in the field of auto parts, can solve the problems of broken tailgate structure, occupying the space of the inner panel of the tailgate, and inability to absorb energy, so as to achieve the effect of improving static stiffness and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

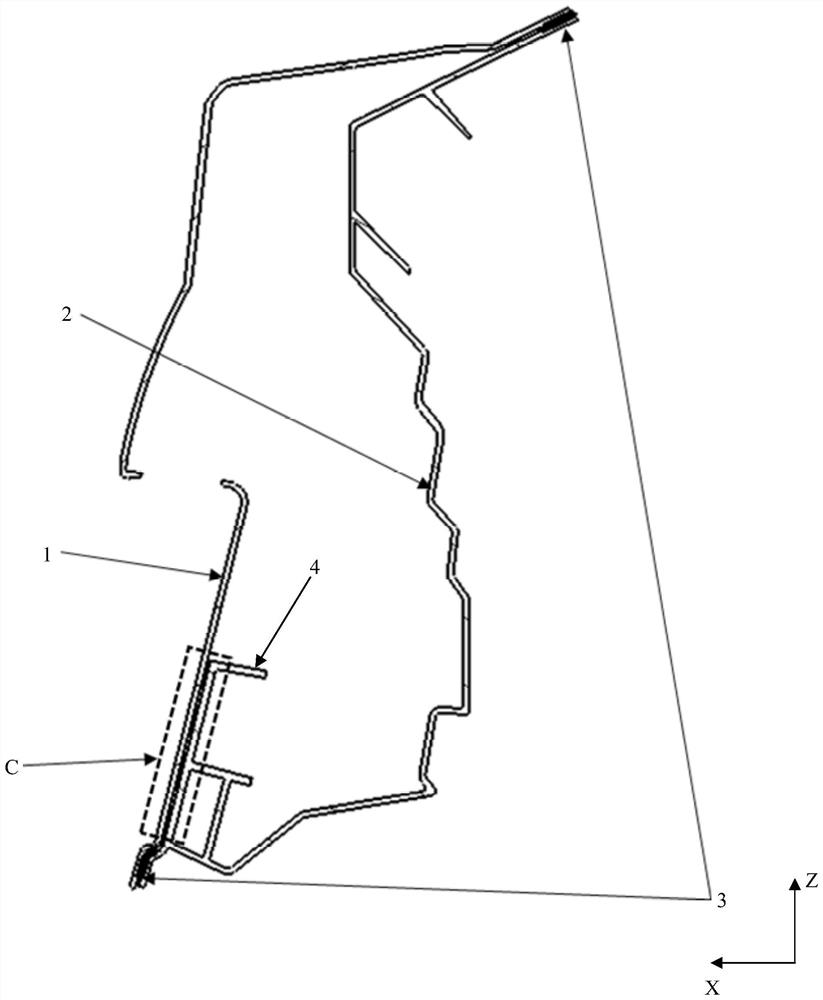

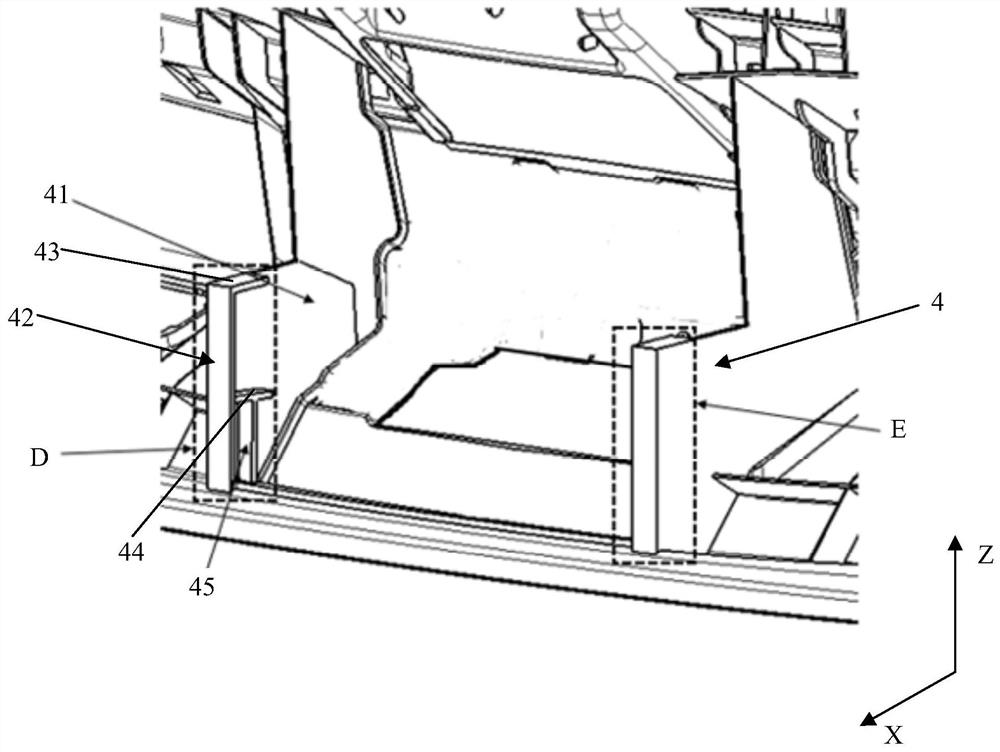

[0040] Such as Figure 1-3 As shown, the embodiment of the present invention provides a tailgate structure, including a tailgate outer panel 1 and a tailgate inner panel 2, the tailgate outer panel 1 and the tailgate inner panel 2 are bonded together by glue 3 around the tailgate outer panel 1, and the tailgate A cavity area is formed between the outer panel 1 and the inner panel 2 of the tailgate. In order to improve the static stiffness of this area and make the overall mode of the tailgate structure, a connecting piece 4 can be arranged in the cavity area. It is connected with the side end of the inner panel 2 of the tailgate and the outer panel 1 of the tailgate. Such as Figure 4 and Figure 5 As shown, the connecting piece 4 includes a first connecting plate 41 and a second connecting plate 42, the first connecting plate 42 is arranged along the X direction, and is used to connect the tailgate inner panel 2 and the second connecting plate 42, and the second connecting...

Embodiment 2

[0051] This embodiment provides an automobile, including the tailgate structure described in Embodiment 1.

[0052]The automobile provided in this embodiment, by adopting the tailgate structure in Embodiment 1, improves the static stiffness and modal of the tailgate of the automobile, and in the event of a collision, the tailgate can play an energy-absorbing role, reducing the destruction level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com