Capsule bottle product and lining assembly equipment

A technology for assembling equipment and capsules, which is applied in the field of capsule bottle products and lining assembling equipment, can solve the problems of manual feeding and boxing speed, boxing accuracy and quality that cannot be effectively controlled, and achieves simple structure, high product compatibility, The effect of stable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

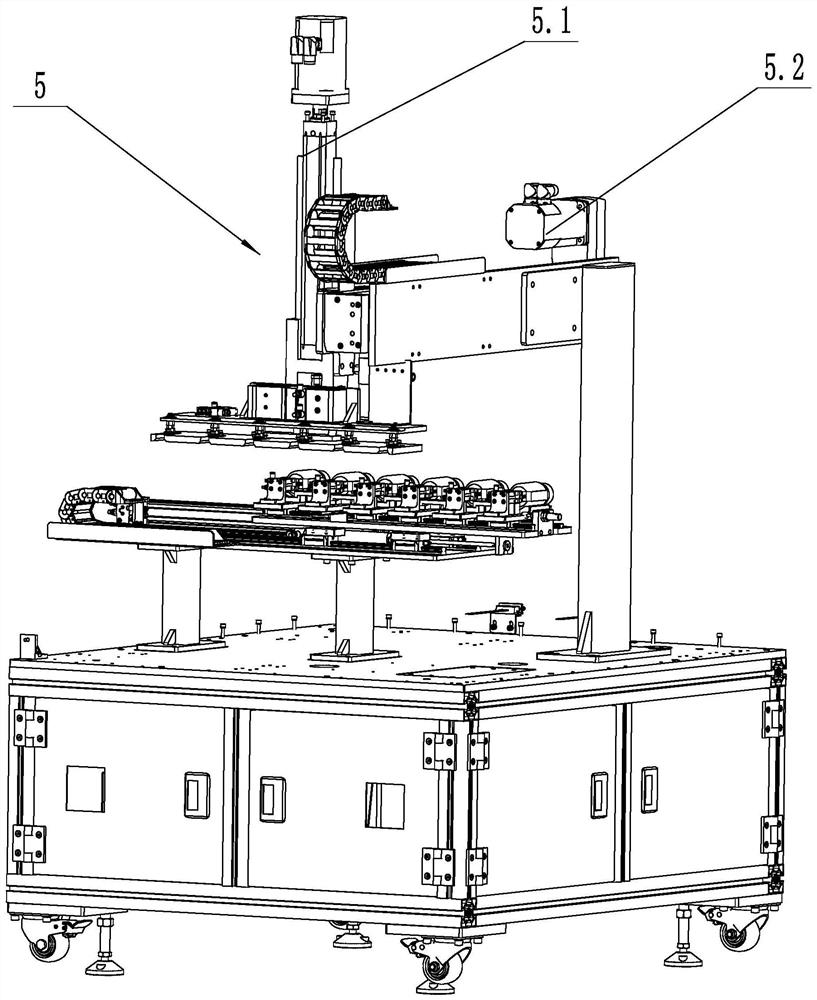

[0055] like figure 1 As shown, a capsule bottle product and lining assembly equipment, including capsule bottle continuous material distribution and positioning mechanism 1, transfer and transportation mechanism 2, product spacing adjustment mechanism 4, automatic feeding system for inner plastic tray and turning mechanism 3 and assembly Agency 5 ( figure 1 The structure of the assembly mechanism 5 is not specifically shown in the figure); the capsule bottle continuous distributing and positioning mechanism 1 is used for distributing and positioning the capsule bottles entering the equipment; the transfer delivery mechanism 2 is used for continuously distributing and positioning the capsule bottles from the capsule bottle Move to the next station on the mechanism; figure 1 and figure 2 As shown, the transfer mechanism includes a transfer frame 2.1, a transfer elevating mechanism 2.2 and a transfer translation structure 2.3. The transfer elevating mechanism and the transfer ...

Embodiment 2

[0058] like Figure 4 and Figure 5 As shown, a capsule bottle continuous distributing and positioning mechanism, including: a support frame 1.1, a lane dividing mechanism 1.2 and two side positioning mechanisms 1.3; the lane dividing mechanism 1.2 includes a lane dividing driver 1.2.1, a side plate 1.2.2 And the dial 1.2.3, the lane dividing mechanism 1.2 is fixed with the support frame 1.1, one end of the dial 1.2.3 is hinged with the side plate 1.2.2, and the lane dividing driving part 1.2.1 drives the dial 1.2.3 to swing; the lane driving Part 1.2.1 is a cylinder, one end of the lane-dividing drive 1.2.1 is hinged with the support, and the telescopic rod of the lane-dividing drive 1.2.1 is hinged with the dial 1.2.3; the entrance of the lane-dividing mechanism 1.2 is provided with a stop plate 1.4 1. Stop drive part 1.5 and entrance detection sensor 1.6, stop drive part 1.5 is a cylinder, and the telescopic rod of stop drive part 1.5 drives stop plate 1.4 to translate, an...

Embodiment 3

[0062] like Figure 5 and Image 6 As shown, on the basis of Embodiment 2, the number of the positioning drive 1.3.3 is multiple, and the positioning drive 1.3.3 corresponds to the conical head 1.3.4.2; the positioning drive 1.3.3 drives the corresponding cone 1.3.4.2 Translation of the shape head. Said structure enables individual control of the conical head 1.3.4.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com