A low-level beam transport vehicle

A low-position technology for beam-carrying vehicles, applied in the field of low-position beam-transporting vehicles, can solve problems such as longitudinal position conflicts, traction system installation position conflicts, and long moving distances of rear beam trolleys, thereby reducing costs, simplifying product structures, and reducing bearing costs. The effect of height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

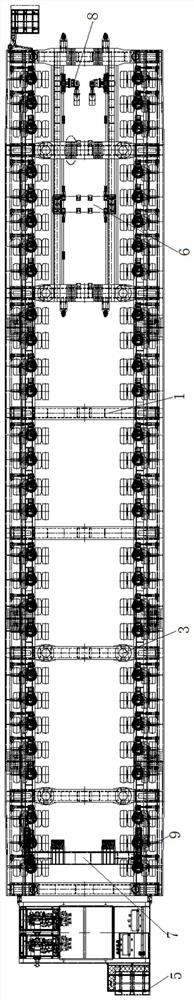

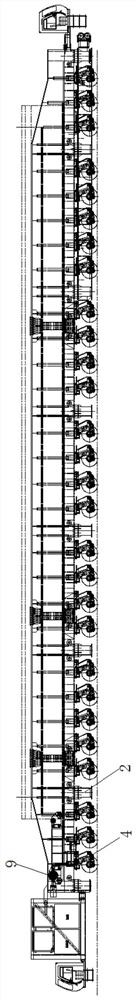

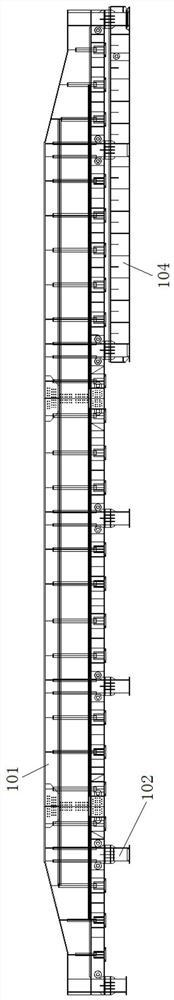

[0033] The low-position beam transport vehicle provided by the present invention has an overall structure such as figure 1 with figure 2 As shown, it includes the frame 1 and the telescopic outrigger 2 installed on the frame, the box beam jacking cylinder 3, the suspension running assembly 4, the steering cylinder, the driver's cab 5, the electrical system and the hydraulic system, and the front section of the frame The front pack beam dolly 6, the back pack beam dolly 7 positioned at the rear section of the vehicle frame, the front traction system 8 for driving the front pack beam dolly and the rear traction system 9 for driving the back pack beam dolly. Among the above components, telescopic outriggers, box girder jacking cylinders, suspension t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com