Garlic harvesting and separating all-in-one machine and using method thereof

An all-in-one, garlic technology, applied in the direction of excavator harvester, harvester, application, etc., can solve the problems of damage to garlic, easy omission, affecting production and sales, etc., and achieve the effect of improving work efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

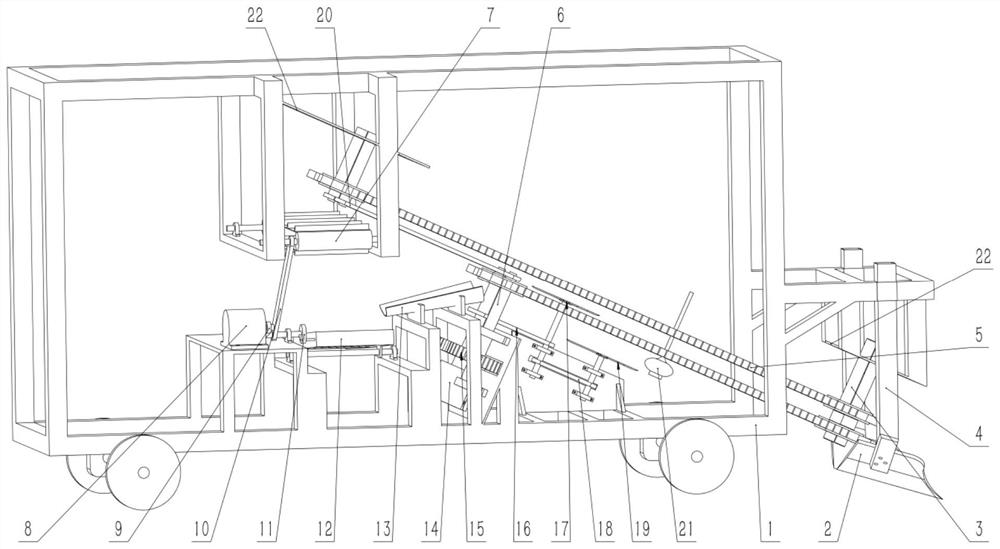

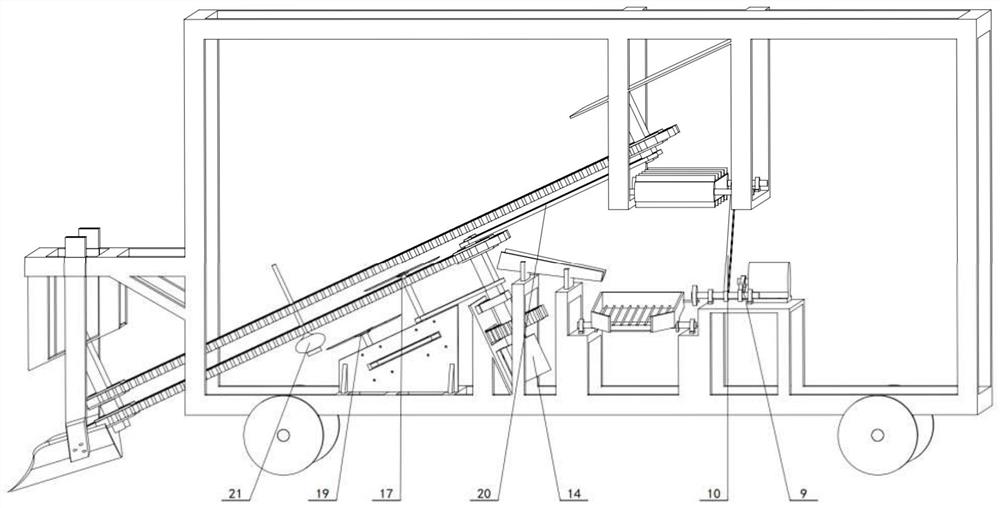

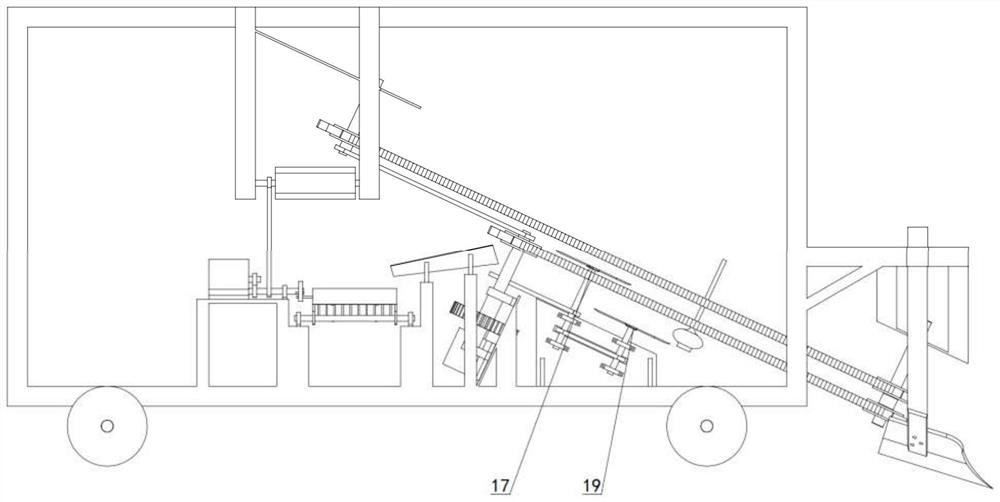

[0043] Such as Figure 1-8 As shown, this embodiment provides a garlic harvesting and separating machine, including a support frame 1, a blade 2, a flexible clamping device 5, a dividing device and a motor A14, wherein the blade 2 is movably arranged on the support frame through an adjustment frame 4 1 front end, the height of the blade is adjusted through the adjustment frame 4, the flexible clamping device 5 is arranged inside the support frame, one end of the flexible clamping device 5 is arranged on the upper side of the blade, and the other end of the flexible clamping device 5 is provided with a splitting device, the splitting device and The flexible clamping devices are all connected to the motor A14, and the flexible clamping device and the dividing device are driven by the motor A14, and the motor A is fixedly arranged on the support frame 1.

[0044] The flexible clamping device 5 includes 2 upper flexible clamping chains and 2 lower flexible clamping chains, the 2 u...

Embodiment 2

[0058] An all-in-one machine for harvesting and separating garlic, the structure of which is as described in Embodiment 1, the difference is that the two ends of the upper flexible clamping chain are respectively provided with connecting plates 22, and the upper flexible clamping chain is connected to the support frame through the connecting plates to ensure the flexibility of the upper part. Integral support for clamping chains.

Embodiment 3

[0060] An all-in-one machine for harvesting and separating garlic, the structure is as described in Example 1, the difference is that a collecting device is arranged at the end of the vibrating sieve, and the collecting device is a woven bag, which is convenient for collecting garlic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com