Large-section wire splicing sleeve steel sheath support and construction method

A technology of connecting pipe and steel sheath, which is applied to overhead line/cable equipment, equipment for connecting/terminating cables, etc. Simple and convenient, improved accuracy, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

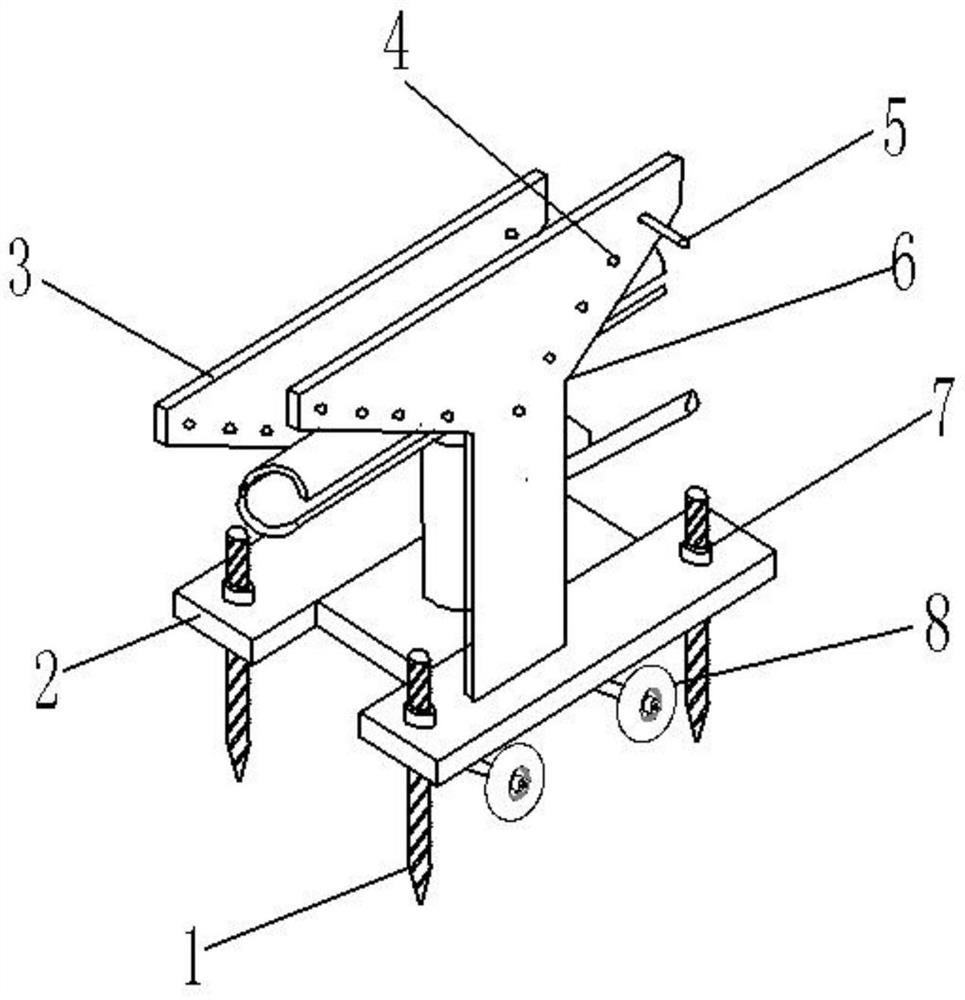

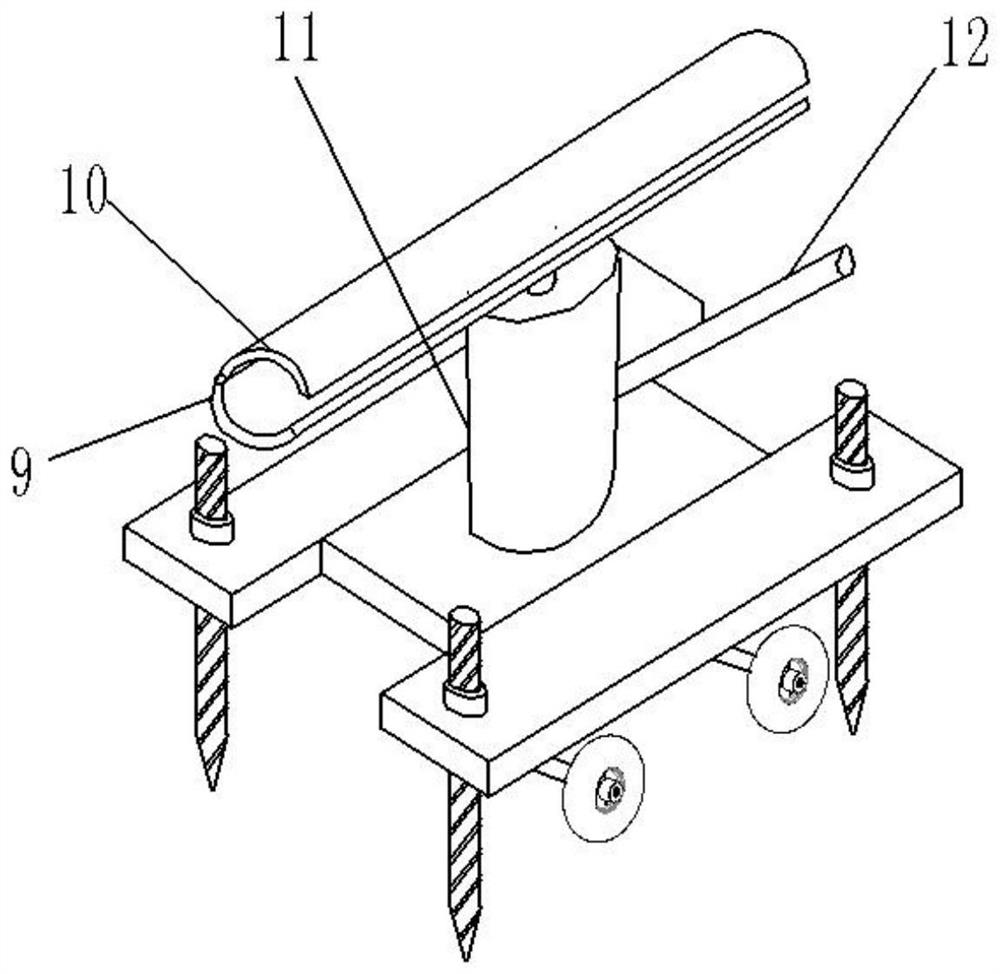

[0030] A large cross-section wire connecting tubular steel sheath bracket, comprising a bracket 2 and a pressure jack 11, the bracket 2 is provided with a pressure jack 11, the pressure jack 11 is a SQD type loose clamp jack, the pressure The jacking machine is composed of an upper chuck, an oil cylinder, a lower chuck and an operating rod. The heavy object can be lifted step by step to a specified height through the operating rod. The SQD type loose clamp jack is stable, safe and reliable, and has an adjustable (micro-drop) function. The lifting height can be controlled more precisely. When the steel sheath is assembled, it can effectively control the lamination gap, making the fastening and alignment more accurate. Accurate, improve bolt tightening efficiency. The upper end of the pressure jacking machine 11 is connected to a fastening device, and a limit device is provided outside the fastening device. The lower end of the limit device is connected to the support 2, and the...

Embodiment 2

[0032] A kind of construction method of a kind of large cross-section wire connecting tubular steel sheath support according to the structure of embodiment 1, concrete steps are as follows:

[0033] (1) Move the bracket 2 to the working position through the universal wheel 8 in the moving assembly, rotate the fastening nut 7, adjust the position of the bottom end of the fixing screw 1 to be lower than the bottom end of the universal wheel 8, until it is inserted into the soil, so that the whole The device is fixed here;

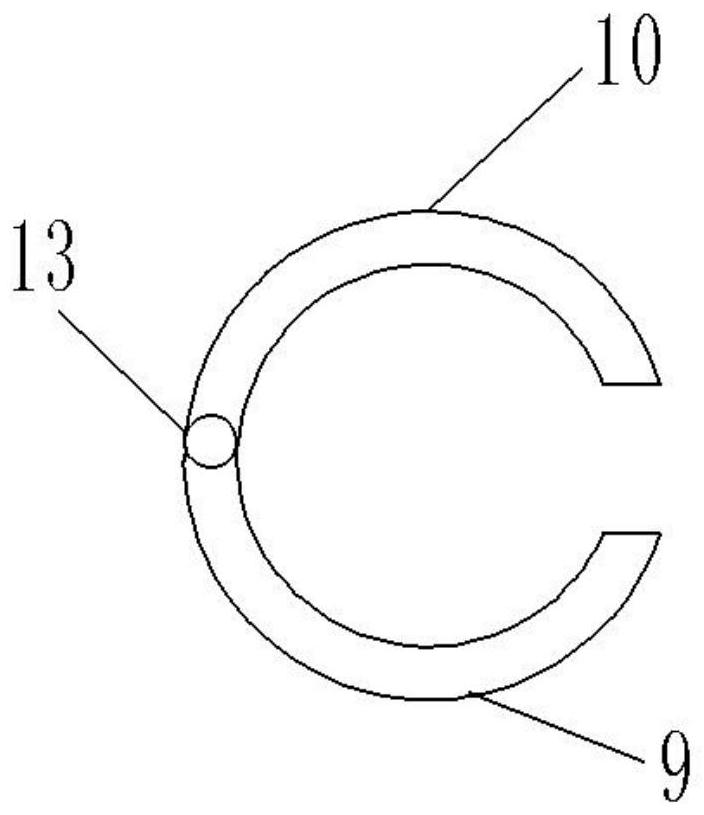

[0034] (2) put the steel sheath on the connecting pipe outside, put the steel sheath connecting pipe into the non-closed annular tube formed by the bottom support 9 and the top cover 10;

[0035] (3) Limit the height of the fastening device through the limit device; determine the required height, select the limit hole 4 with a suitable height, and pass the limit rod 5 through the first limit plate 3 and the second limit plate 6 Symmetry The limit hole 4; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com