Four-way casing quick-mounting structure applied to oil well

A casing and oil well technology, which is applied in the field of spool casing quick-installation structure, can solve the problems of manual disassembly and assembly, reduce the assembly speed of spool casing, and difficulty in flange sealing connection, etc. The effect of the simple process of connection, guaranteed connection, installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

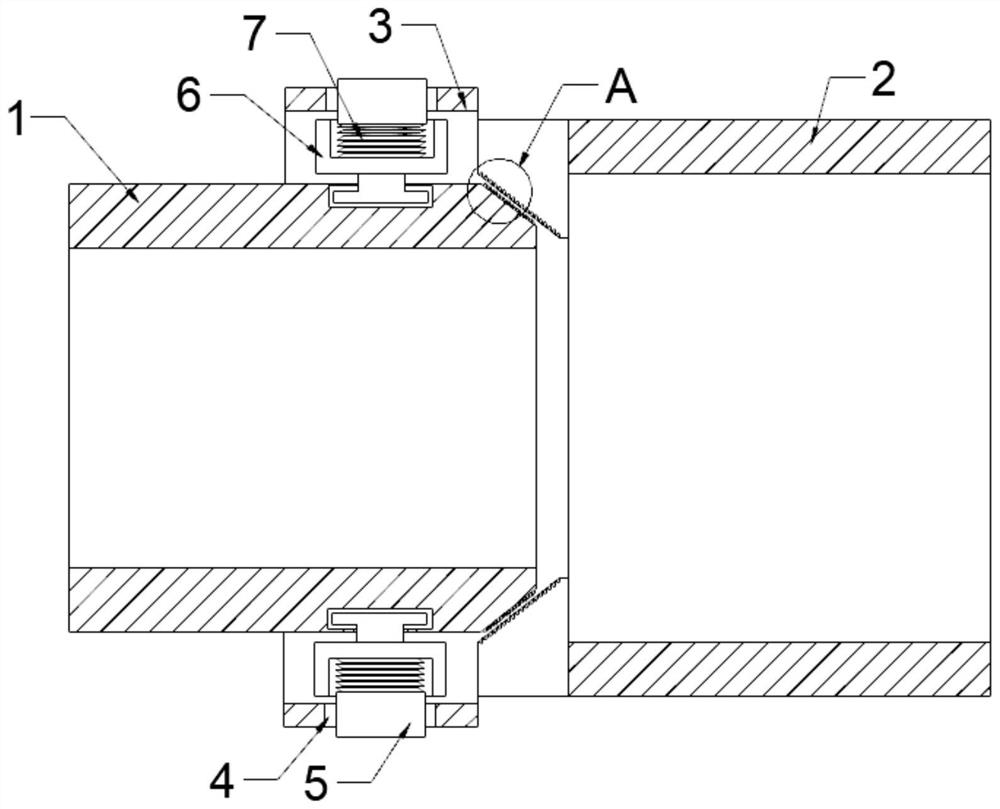

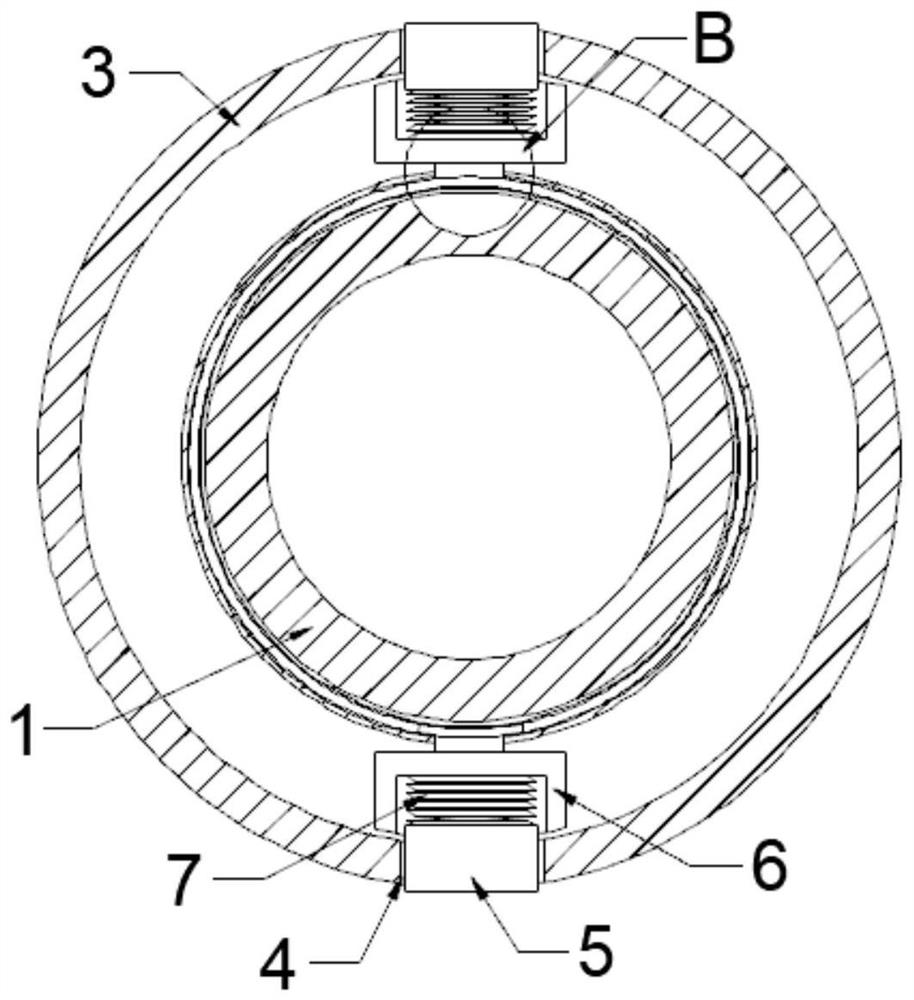

[0034] refer to Figure 1-4 , a four-way casing quick-installation structure applied to oil wells, the four-way casing quick-installation structure includes:

[0035] The sleeve body, the sleeve body includes the first sleeve 1, the second sleeve 2 and the connecting pipe 3, the diameter of the second sleeve 2 is larger than the diameter of the first sleeve 1, and the first sleeve 1 is connected to the second sleeve through the connection mechanism. The pipe 2 is connected, the connecting pipe 3 is fixedly connected with the end of the second casing 2 close to the first casing 1, and the diameter is larger than the second casing 2, and the connecting pipe 3 is sleeved on the first casing 1;

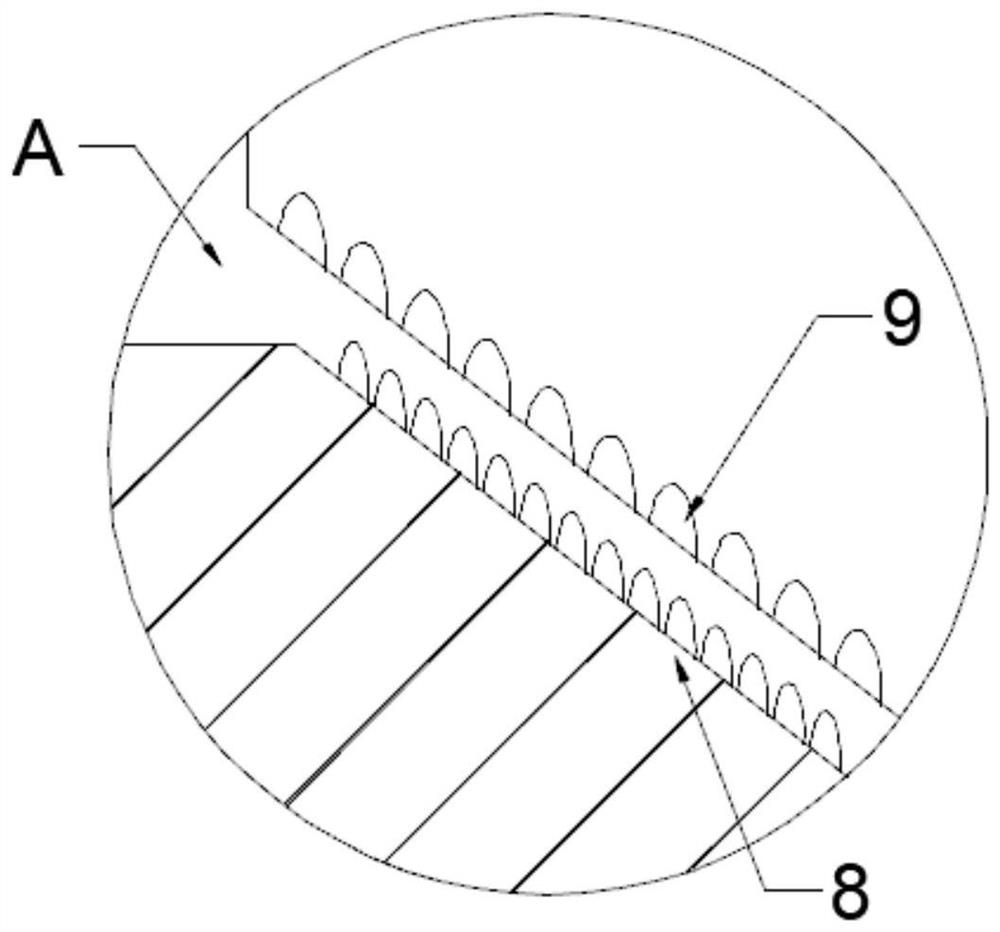

[0036] The limit mechanism, the limit mechanism includes a limit port 4, a limit block 5, a mounting block 6 and a spring 7, two limit ports 4 are set at the opposite ends of the connecting pipe 3, and two mounting blocks 6 are provided with installation slot, and is slidably installed o...

Embodiment 2

[0044] refer to Figure 5-7 The difference between this embodiment and the first embodiment is that the connecting pipe 3 and the first sleeve 1 are fixedly connected by a reinforcement mechanism, and the reinforcement mechanism includes a bayonet 13, a bayonet 14 and a fixing rod 15, and the two bayonets 13 are opposite to each other. It is set on both sides of the connecting pipe 3, and the connecting line of the bayonet 13 is perpendicular to the connecting line of the limit port 4, the slot 14 is oppositely set on the surface of the first casing 1, and the fixing rod 15 is set inside the bayonet 13 and the slot 14 ;

[0045] The side wall of the fixed rod 15 is provided with a plurality of strip grooves 16, and the inside of the strip groove 16 is fixedly connected with a support foot 17. The support foot 17 is made of an elastic material, and the expanded width is greater than the diameter of the limit port 4, and the strip groove 16 is to have a place to place the brace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com