Adjustable textile stock bin management device

A management device and adjustable technology, applied in the textile field, can solve the problems of controlled discharge, inability to fully mix materials, and unfavorable scientific management of textile silos.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

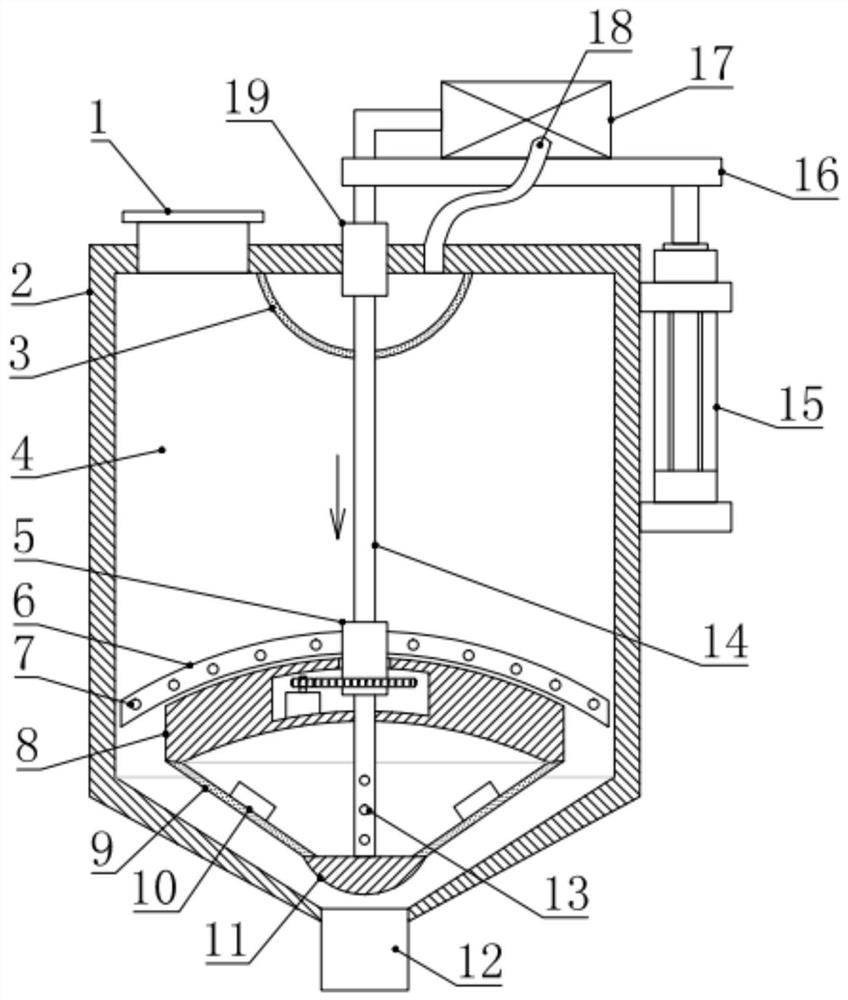

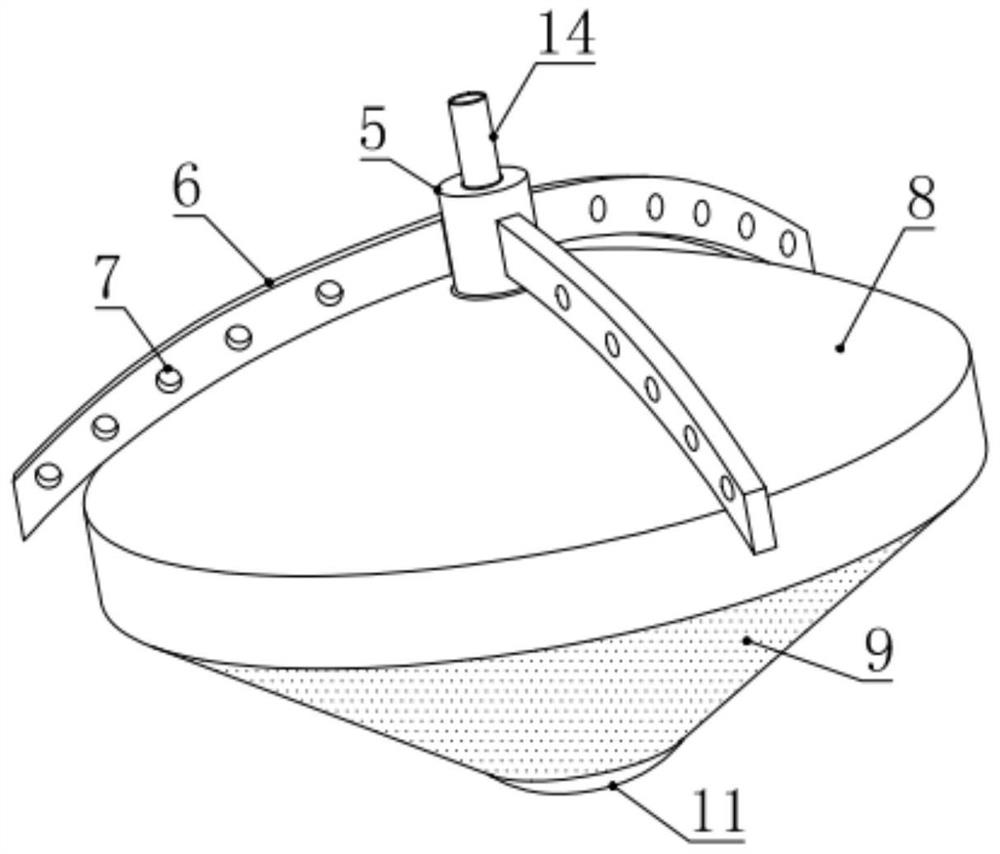

[0023] see figure 1 , in an embodiment of the present invention, an adjustable textile silo management device includes a textile silo 2, the top of the textile silo 2 is provided with a feed port 1, and the middle of the bottom of the textile silo 2 is provided with a discharge pipe 12. The inner cavity of the textile silo 2 is a material cavity 4, and an air intake pipe 14 is installed in the middle of the material cavity 4, and a fixed frame 16 is installed and fixed on the air intake pipe 14 on the upper side of the textile silo 2. The outer side is also provided with a telescopic cylinder 15 for driving the integral movement up and down formed by the air intake pipe 14 and the fixed frame 16. The fixed frame 16 is also equipped with a temperature control fan 17 communicating with the upper end of the air intake pipe 14. The material chamber 4. A deflector 8 is installed and fixed on the inlet pipe 14 at the lower part, and the middle part of the deflector 8 is provided wit...

Embodiment 2

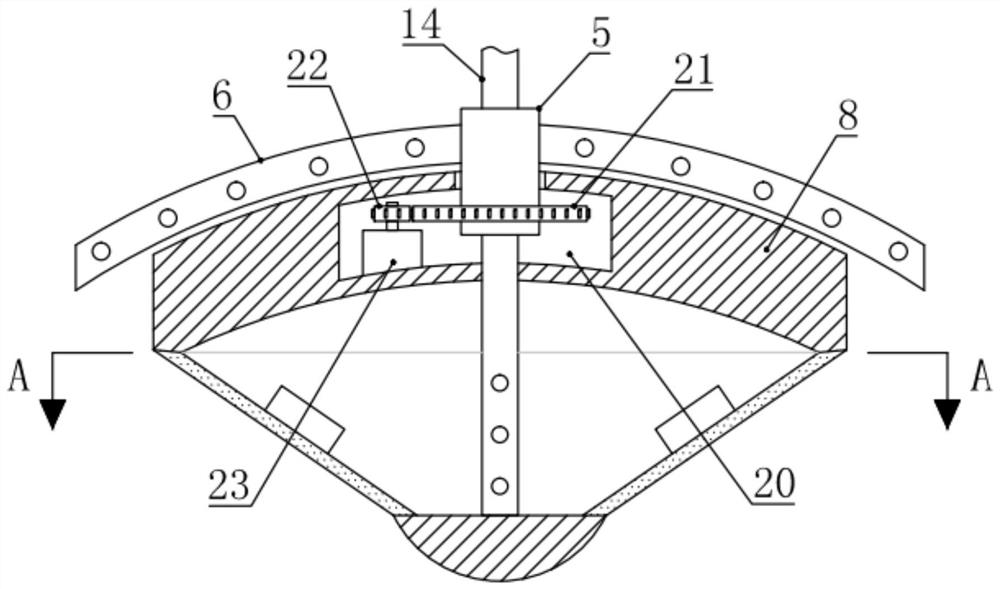

[0026] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0027] In this embodiment, the lower part of the material chamber 4 is conical, and the upper part of the material chamber 4 is a cylindrical structure; the air inlet pipe 14 is an L-shaped structure, and the vertical part of the air inlet pipe 14 is coaxially arranged with the material chamber 4 , the vertical portion of the air intake pipe 14 stretches out from the top of the textile silo 2, and the top of the textile silo 2 is equipped with a guide sleeve 19 that slides with the vertical portion of the air intake pipe 14, through which the guide sleeve 19 For stable guidance of the intake pipe 14 .

[0028] In the middle of the top of the material cavity 4, a hemispherical dust-proof net 3 is also installed, which is used to stop dust by the dust-proof net 3; The air inlet of the temperature-controlled fan 17 communicates with the inner space of the dust filter 3 through the return air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com