Electromagnetic type pipeline welding aligning device and working method

A counterpart, electromagnetic technology, applied in welding equipment, auxiliary welding equipment, electromagnetic wave re-radiation and other directions, can solve the problems of insufficient counterpart accuracy, inconvenient detection, etc., and achieve the effects of poor accuracy, convenient counterpart detection, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

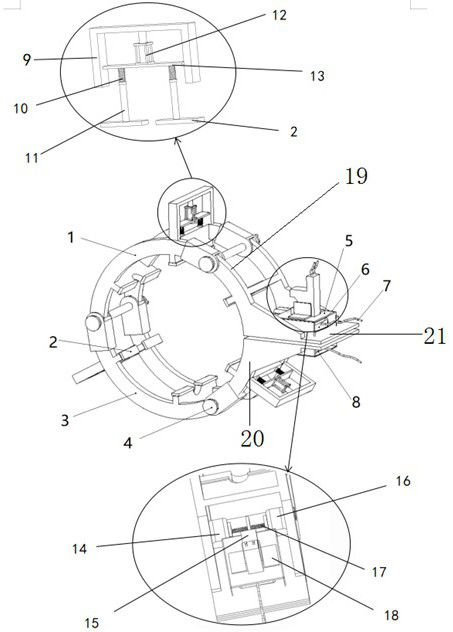

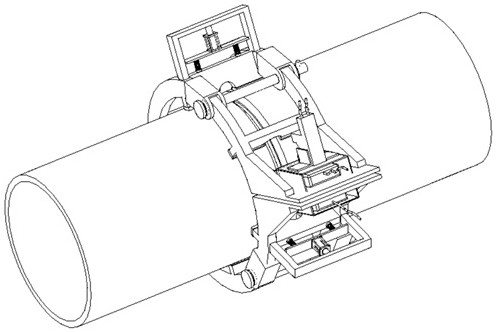

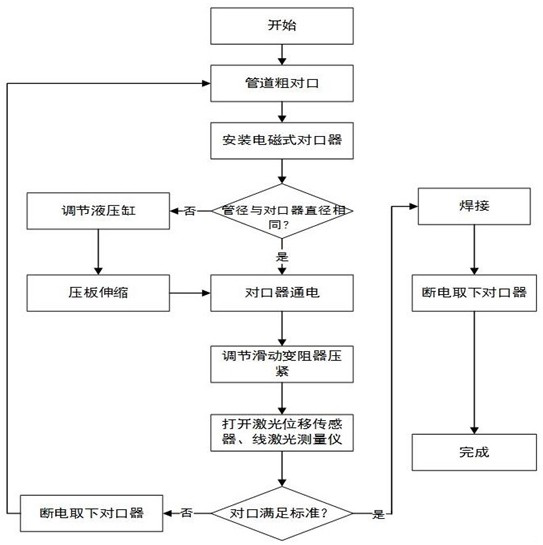

[0025] like figure 1 , 2 As shown, an electromagnetic pipe welding counterpart includes an upper annular cage 1 and a lower annular cage 3 hinged up and down; the end of the upper annular cage 1 away from the hinge is connected to the upper end 19 through a latch 4; The end of the frame 3 away from the hinge is connected to the lower end 20 through the latch 4; the upper annular cage 1, the lower annular cage 3, the upper end 19 and the lower end 20 form a ring frame as a whole; the outer side of the ring frame is provided with three support frames 9; The three supporting frames 9 divide the ring frame into three sections; the ring frame is a hollow structure as a whole.

[0026] The inner top of the support frame 9 is provided with a hydraulic cylinder 12; the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com