Flattening machine for material printing

A technology of flattening machine and printing mechanism, which is applied in the direction of printing machine, flat flat printing machine, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A flattening machine for material printing, such as figure 1 As shown, it includes a bottom plate 1, a base 2, a cylinder 3, a push rod 4, a printing mechanism 5, and a printing pressure mechanism 6. A base 2 is provided on the left front side of the top of the bottom plate 1, and a cylinder 3 is arranged in the base 2. On the telescopic rod of the cylinder 3 A push rod 4 is connected, a printing mechanism 5 is connected between the push rod 4 and the base plate 1, a printing press mechanism 6 is connected between the front and rear sides in the middle of the bottom plate 1 top, and the parts of the printing press mechanism 6 are connected with the parts of the printing mechanism 5.

[0066] When people need to press the material, people first place the material under the parts of the pressing mechanism 6, and then people start the cylinder 3, and the telescopic rod of the cylinder 3 moves to the right to drive the push rod 4 to move to the right, and the push rod 4 move...

Embodiment 2

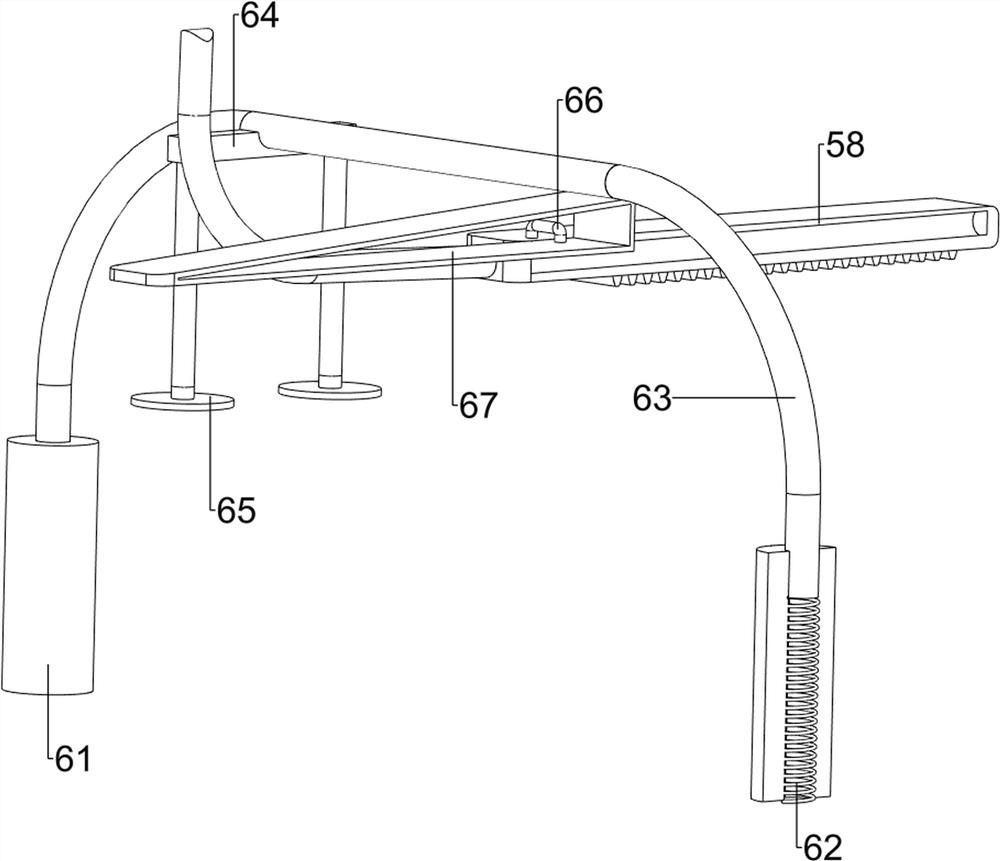

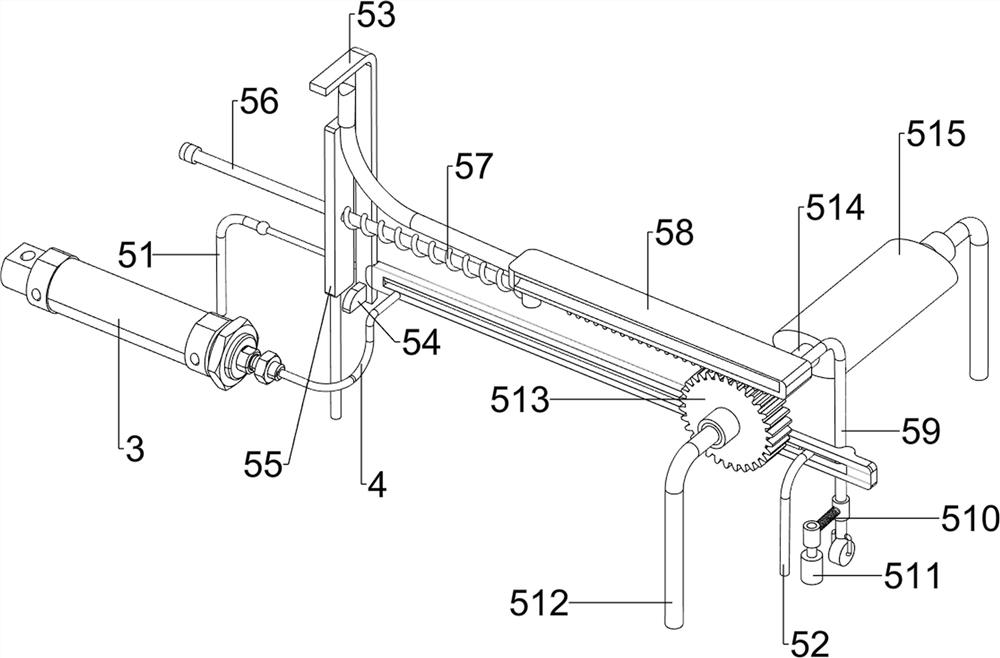

[0068] On the basis of Example 1, such as figure 2 and image 3 As shown, the printing mechanism 5 includes a first support 51, a second support 52, a first slide bar 53, an iron block 54, a third support 55, a second slide bar 56, a first spring 57, a rack bar 58, a wheel Frame 59, second spring 510, fixed seat 511, fourth support 512, full gear 513, cylindrical rod 514 and printer 515, base plate 1 top left front side is provided with first support 51, base plate 1 top right side is provided with second Support 52, the left side of the first support 51 is slidingly connected with the first sliding rod 53, the bottom of the first sliding rod 53 is provided with an iron block 54, the left front side of the bottom plate 1 is provided with a third support 55, and the third support 55 is located on the base 2 On the right side, the third support 55 middle part is slidably connected with a second slide bar 56, and the right part of the second slide bar 56 is connected with a rac...

Embodiment 3

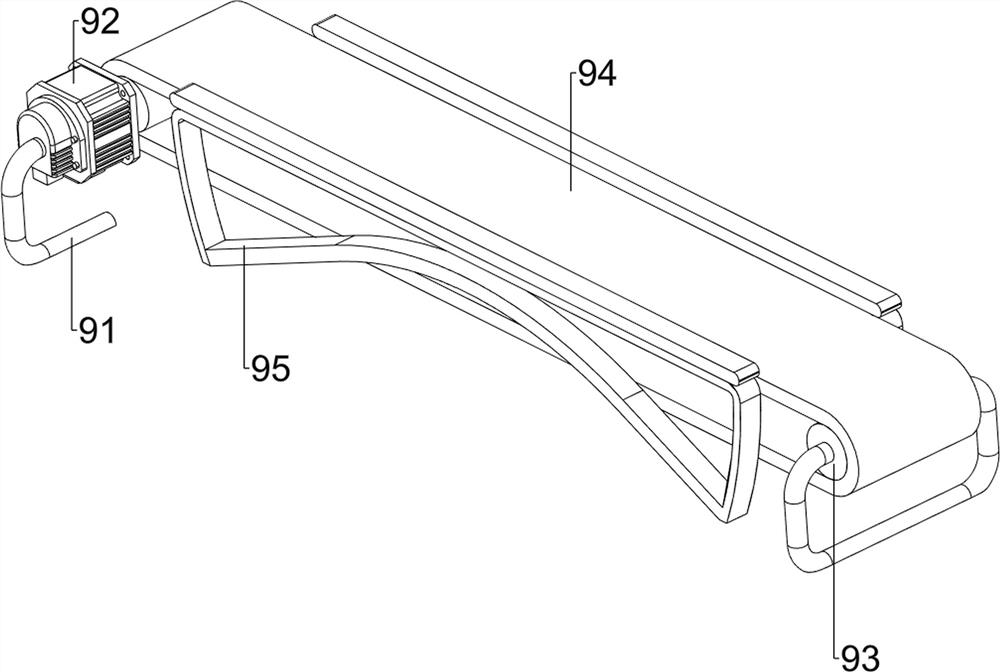

[0073] On the basis of Example 2, such as figure 1 , Figure 4 and Figure 5 As shown, also includes feeding mechanism 9, and feeding mechanism 9 includes the 6th support 91, intermittent rotating motor 92, runner 93, conveyer belt 94 and retaining frame 95, bottom plate 1 rear side top left and right sides are all provided with two A sixth support 91, the sixth support 91 on the right rear side is provided with an intermittent rotating motor 92, and the sixth support 91 on the same side is connected with a running wheel 93 in a rotating manner, and the output of the right running wheel 93 and the intermittent rotating motor 92 The shafts are connected, and a conveyor belt 94 is connected between the runners 93. Two material retaining frames 95 are arranged on the rear side of the top of the base plate 1, and the material retaining frames 95 are respectively located on both sides of the conveyor belt 94.

[0074] When people need to convey materials, people first place the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com