Atomization device and special atomization disc thereof

A technology of atomizing device and atomizing disc, which is applied in the direction of spraying device and liquid spraying device, etc., which can solve the problems of poor use effect, ineffective and uniform diffusion of liquid, and insufficient uniform atomization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

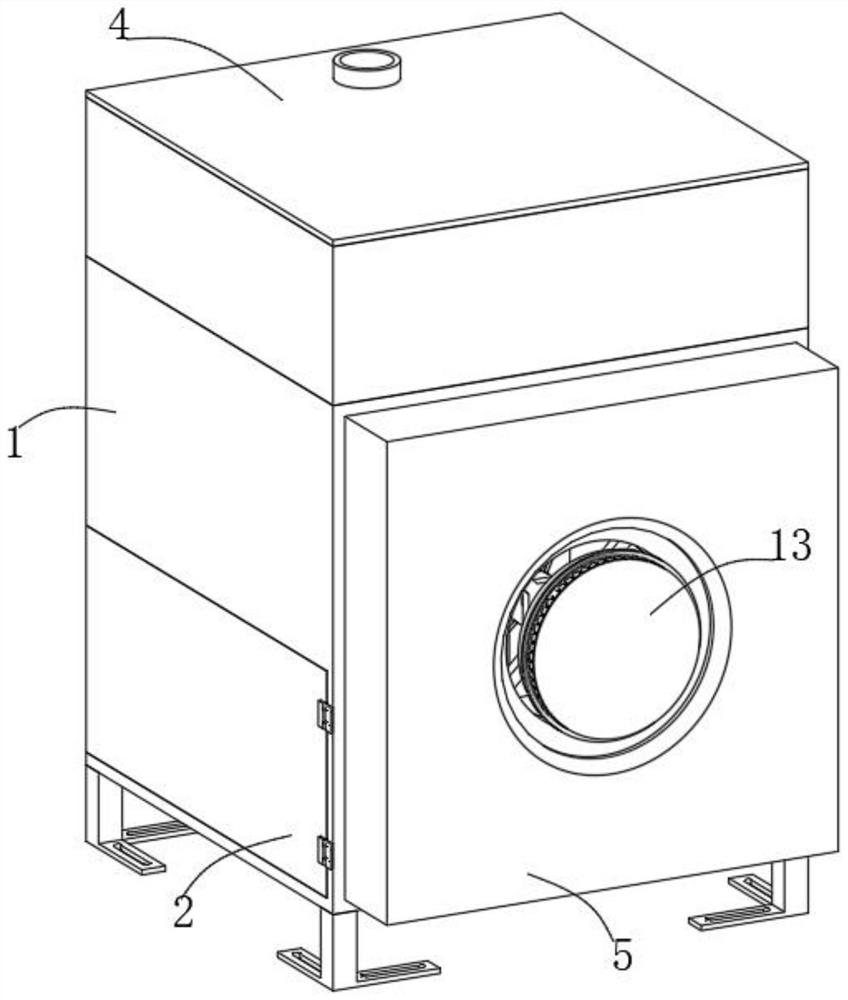

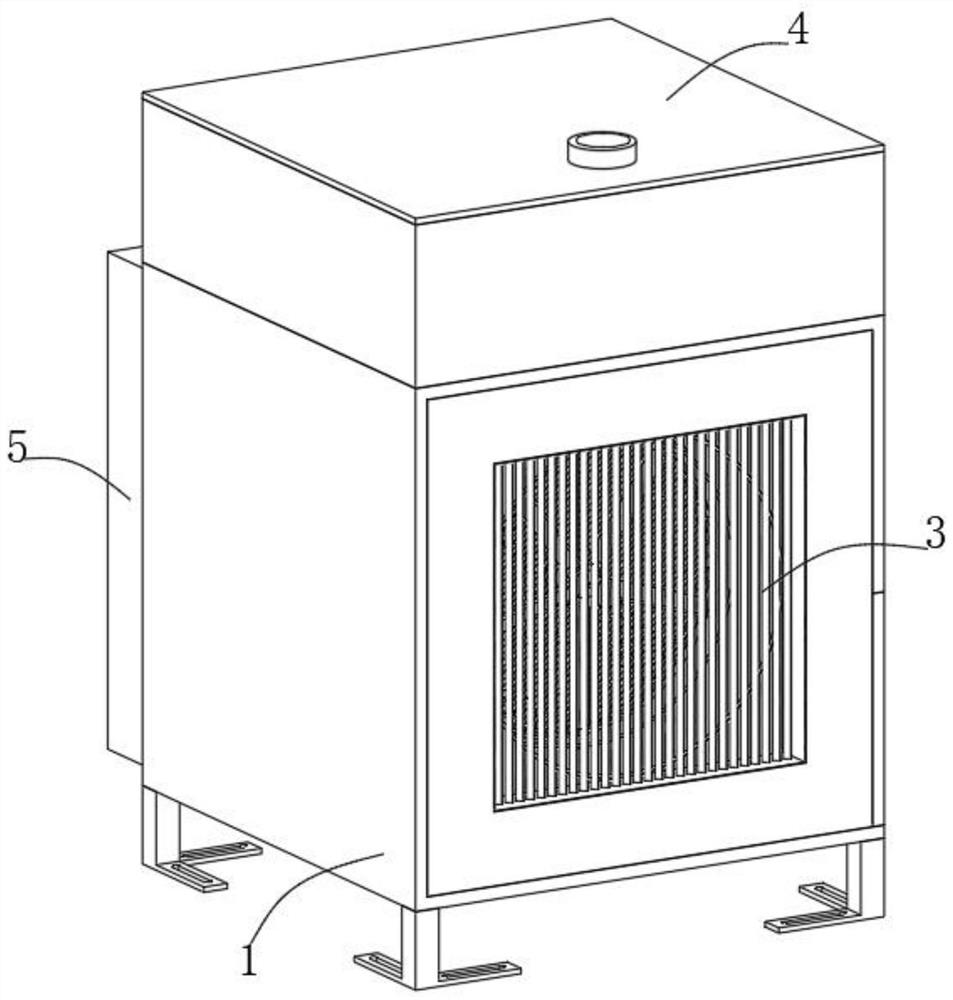

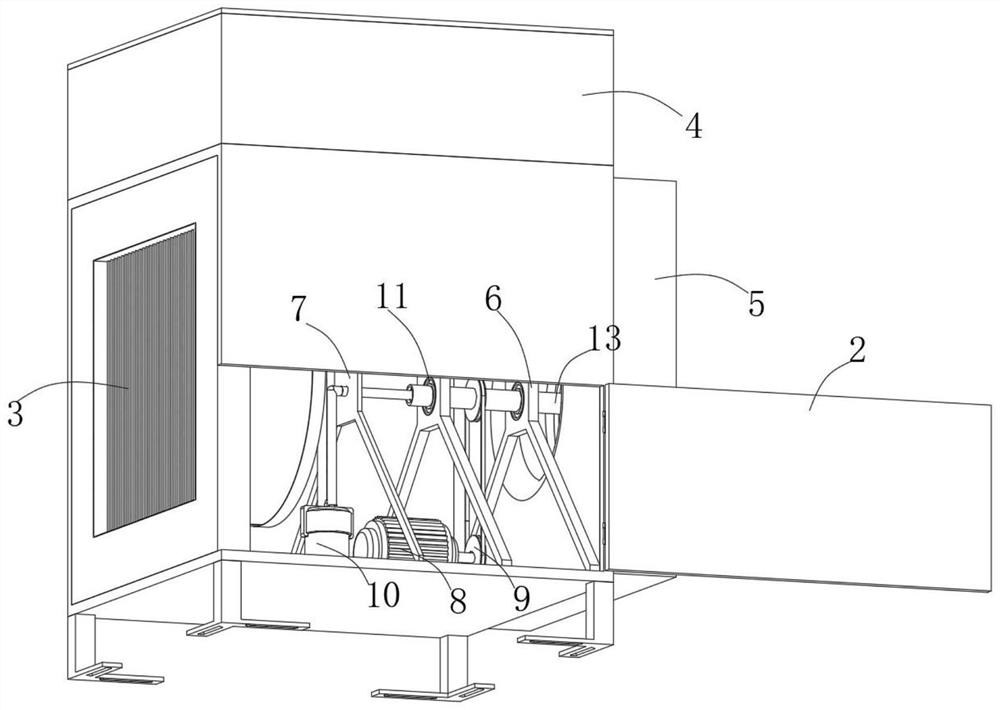

[0029] Embodiment one, with reference to Figure 1-10: An atomization device and its special atomization disc, comprising a bottom frame 1 and an atomization disc mechanism 13, the establishment of the bottom frame 1 provides the installation basis for other functional components of the equipment, and the establishment of the atomization disc mechanism 13 enables the equipment to For the atomization treatment of the liquid, the front surface of the bottom frame 1 is embedded with an air guide block 5, and the establishment of the air guide block 5 facilitates the opening of the air guide port, and the rear surface of the bottom frame 1 is provided with an air inlet, which is convenient for setting up the air inlet The installation of the fan 3 is carried out, and the fan 3 is embedded inside the air inlet. The establishment of the fan 3 can effectively provide a strong flow of air, so that the atomized liquid can spread to a farther area. The structure of the fan 3 The princip...

Embodiment 2

[0030] Embodiment two, refer to Figure 3-10 : The outer surface of one side of the bottom frame 1 is provided with an installation opening near the edge of the bottom. The establishment of the installation opening is convenient for maintenance of the internal functional parts of the equipment. The establishment of the door 2 and the protective door 2 can effectively seal the inner space of the bottom frame 1, and the center of the front surface of the air guide block 5 is provided with an air guide port. The liquid reaches a remote area, and the interior of the air guide port is connected to the interior of the bottom frame 1. The output end of the motor 8 is also set with a pulley 9, and a belt is set between the outer surfaces of the two pulleys 9. The top of the liquid inlet pipe 12 runs through the bottom frame 1 top, and the top of the liquid inlet pipe 12 extends to the inside of the liquid storage frame 4. The establishment of this structure enables the liquid inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com