A rotary blanking device for table tennis production

A blanking device and table tennis technology, applied to balls, sports accessories, etc., can solve the problems of slow table tennis blanking, sore arms, increased workload of workers, etc., to facilitate collection, increase blanking speed, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

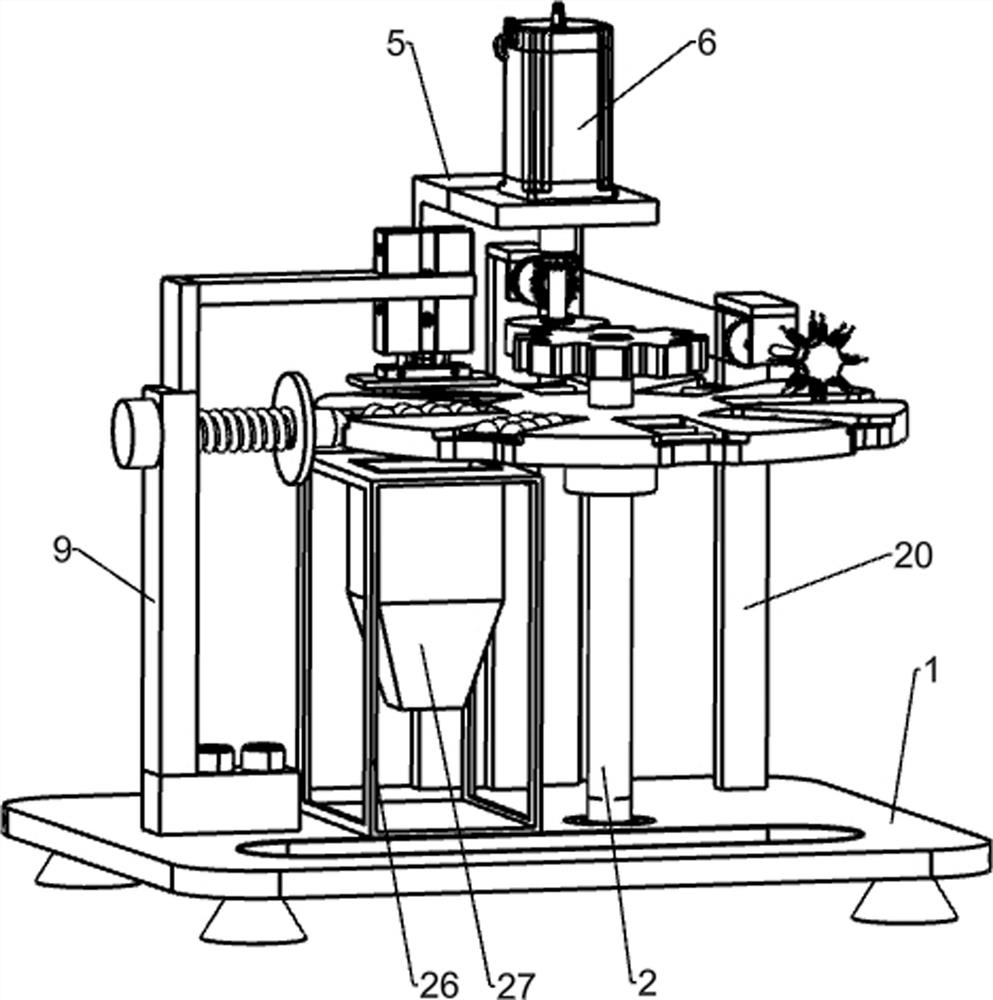

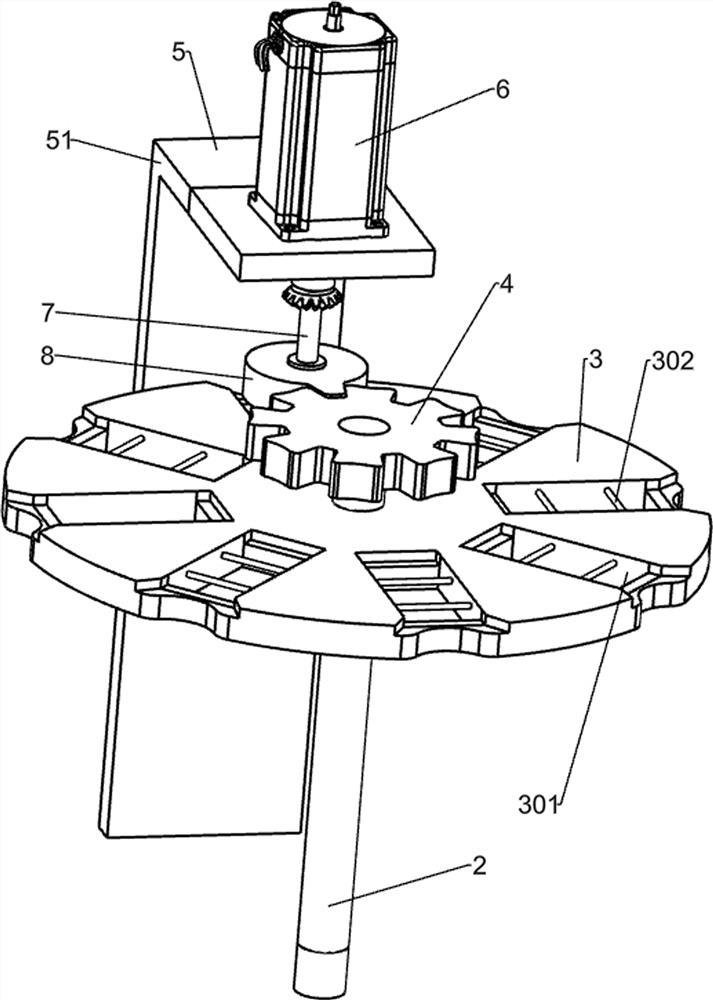

[0025] A blanking device for rotary table tennis production, such as Figure 1-2 As shown, it includes a workbench 1, a first rotating shaft 2, a circular disc 3, a bearing rod 302, a spur gear 4, an intermittent rotation mechanism 5 and a pressing mechanism 9. The first rotating shaft 2 is rotatably installed on the workbench 1, and the second The upper part of a rotating shaft 2 is fixed with a circular disc 3, and eight placing grooves 301 are arranged on the circumferential wall of the circular disc 3, and at least four bearing rods 302 are connected in the placing grooves 301, and the first on the upper side of the circular disc 3 A spur gear 4 is fixed on the rotating shaft 2, an intermittent turning mechanism 5 is arranged on the workbench 1 on the rear side of the first rotating shaft 2, and the intermittent turning mechanism 5 cooperates with the spur gear 4, and the workbench 1 on the left side of the first rotating shaft 2 is provided with Press mechanism 9.

[002...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 1-3 As shown, the intermittent rotation mechanism 5 includes a mounting frame 51, a reduction motor 6, a second rotating shaft 7 and a missing gear 8. The mounting frame 51 is fixed on the workbench 1, and the mounting frame 51 is positioned at the rear side of the first rotating shaft 2. The frame 51 is provided with a reduction motor 6 by bolts, the output shaft of the reduction motor 6 passes through the mounting frame 51, and the output shaft of the reduction motor 6 is fixedly connected with the second rotating shaft 7, and the missing gear 8 is installed on the second rotating shaft 7. Gear 8 meshes with spur gear 4 .

[0029] When blanking the table tennis ball after production, start the reduction motor 6 to rotate, the output shaft of the reduction motor 6 drives the second rotating shaft 7 to rotate, the second rotating shaft 7 drives the missing gear 8 to rotate, and the missing gear 8 drives the spur gear 4 to rotat...

Embodiment 3

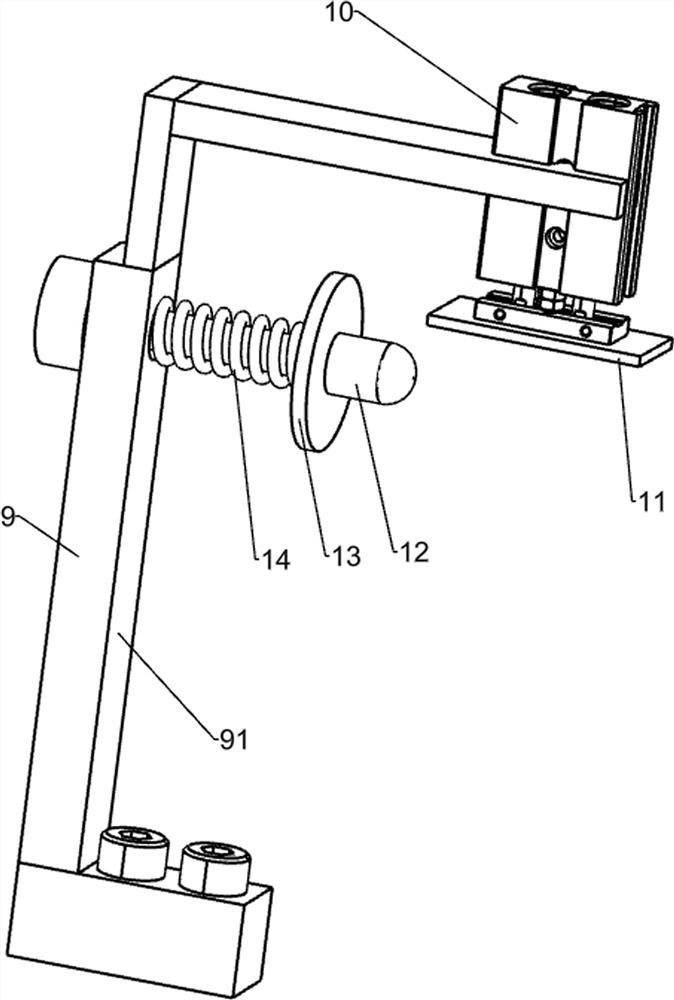

[0033] On the basis of Example 2, such as Figure 1-4 As shown, it also includes a slide bar 12, a baffle plate 13 and a first spring 14, and the right side of the fixed frame 91 is slidably connected with a slide bar 12, and the slide bar 12 is positioned at the lower side of the reciprocating cylinder 10, and one end of the slide bar 12 is connected to the circular The edge of the disc 3 is in contact with the arc-shaped groove, the slide bar 12 is equipped with a baffle plate 13 , the first spring 14 is sleeved on the slide bar 12 , one end of the first spring 14 is fixedly connected to the fixing frame 91 , and the other end is fixedly connected to the baffle plate 13 .

[0034] Initially, the first spring 14 is in a compressed state, and the reduction motor 6 is started to rotate. When the intermittent rotation mechanism 5 drives the table tennis ball on the placement groove 301 to be perpendicular to the pressing plate 11, the first spring 14 resets, so that the slide bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com