Method for transporting and installing aerated concrete wallboard

A technology of aerated concrete and installation method, which is applied in construction, building construction, construction material processing, etc., can solve problems such as vertical transportation difficulties, damage, and wall panel breakage, and achieve high construction efficiency, convenient disassembly, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

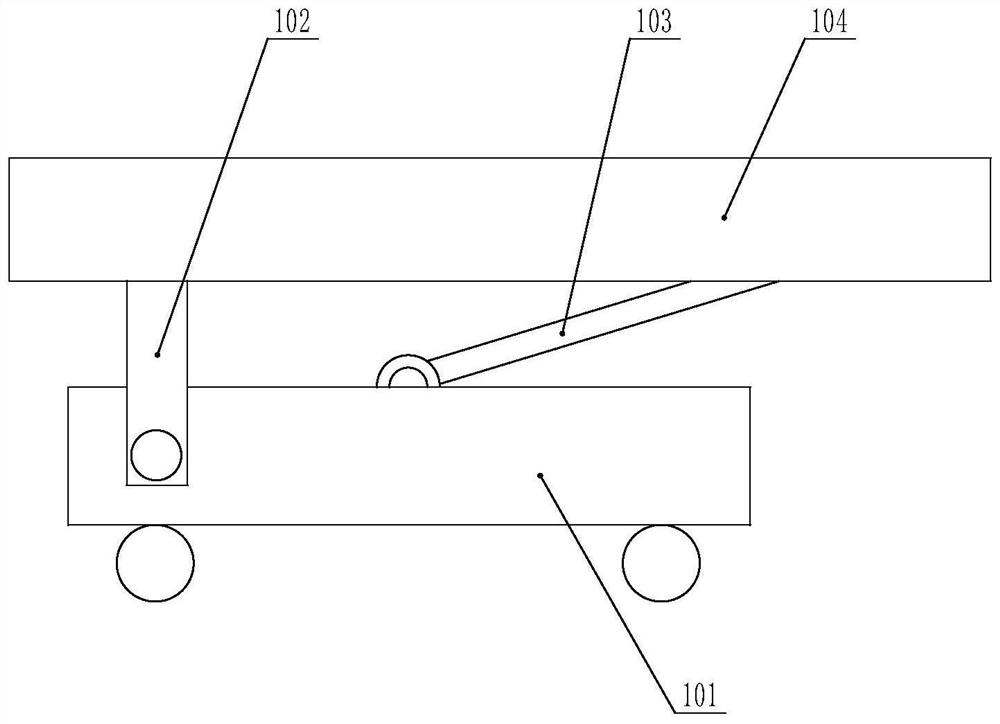

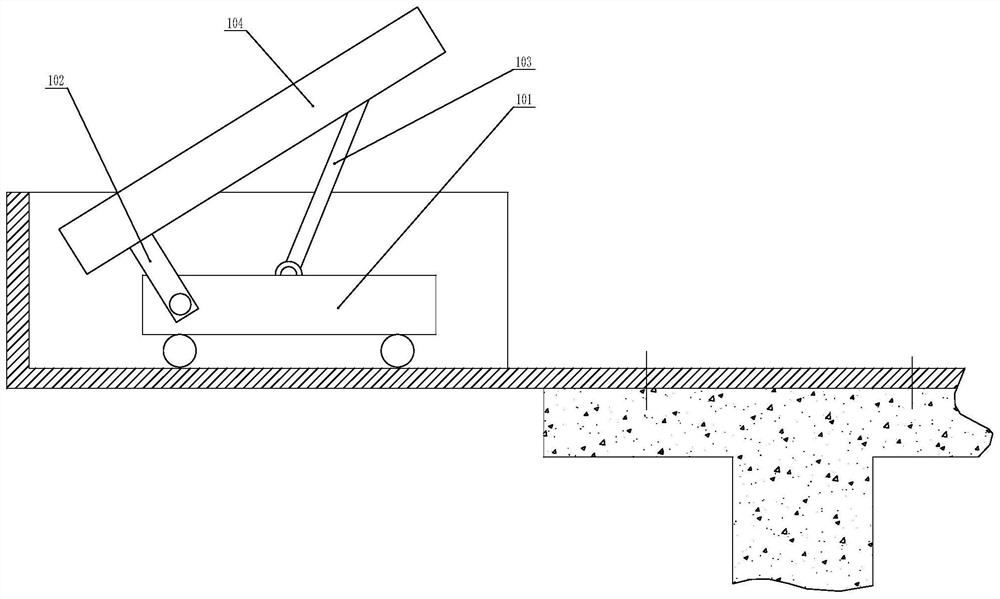

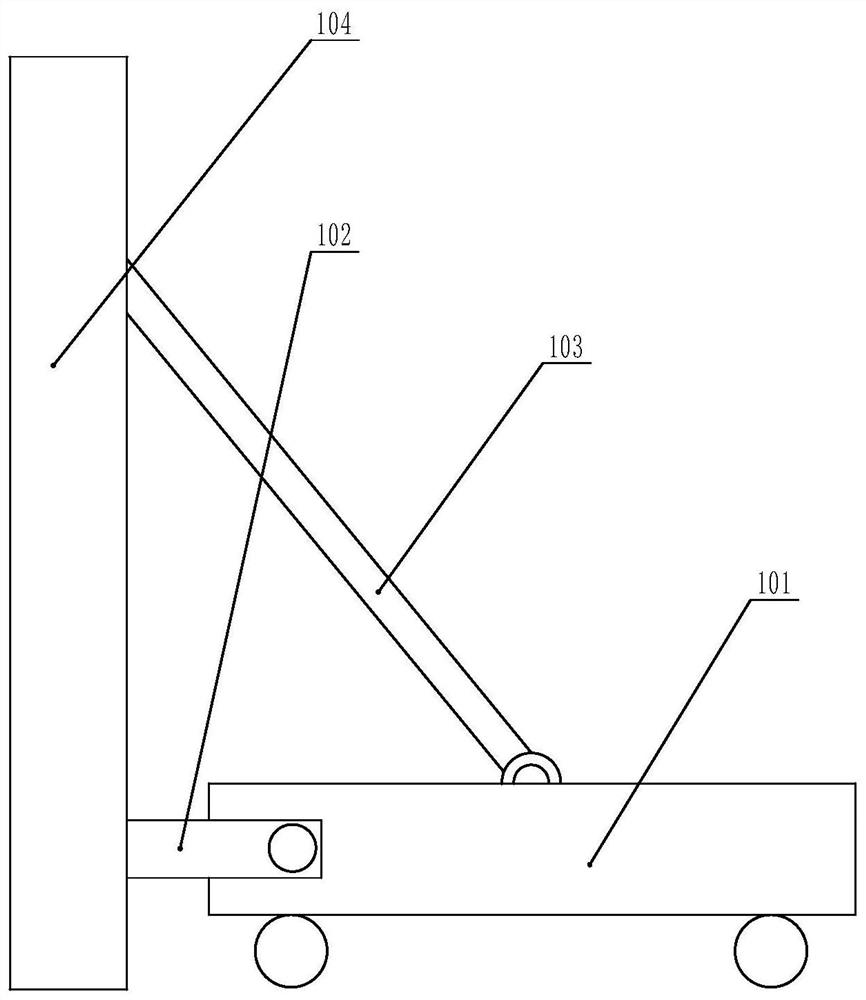

[0030] Embodiment: a method for transporting and installing an aerated concrete wall panel, comprising the following steps: as Figure 1-6 as shown,

[0031] 1) Move a transfer installation device to a designated position, the transfer installation device includes a carrying trolley 101, the carrying trolley 101 can be an automatic trolley or a hand-push trolley; a transfer device 104 is installed on the carrying trolley 101 . And adjust the transfer device 104 on it to a horizontal state;

[0032] 2) Hoist the concrete wall panel into the transfer device 104 on the transfer installation device, and fix the concrete wall panel; the transfer device 104 includes a rectangular support plate 1 on which a There is an accommodating groove 2 for storing concrete wall panels; one end of the accommodating groove 2 runs through one end of the supporting plate 1 to form an open end; a limiting device is detachably installed on the supporting plate 1, and the limiting device can Confin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com