A threading device for an extruder

A technology of threading device and extruder, applied in the direction of conductor/cable insulation, coating, etc., can solve the problems of high labor intensity and cumbersome wiring operation, and achieve the effect of reducing labor intensity and making it easier to go online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

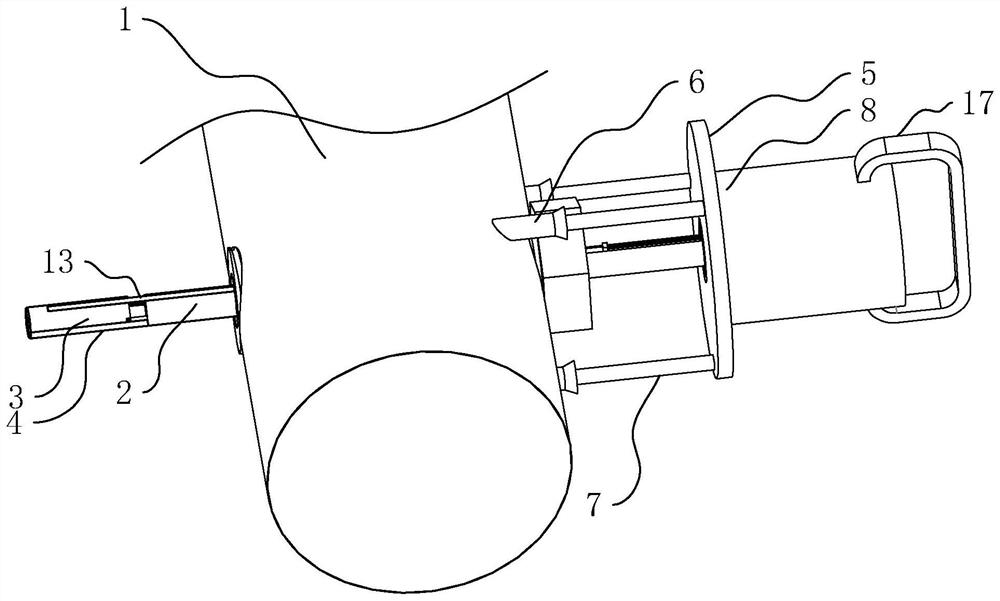

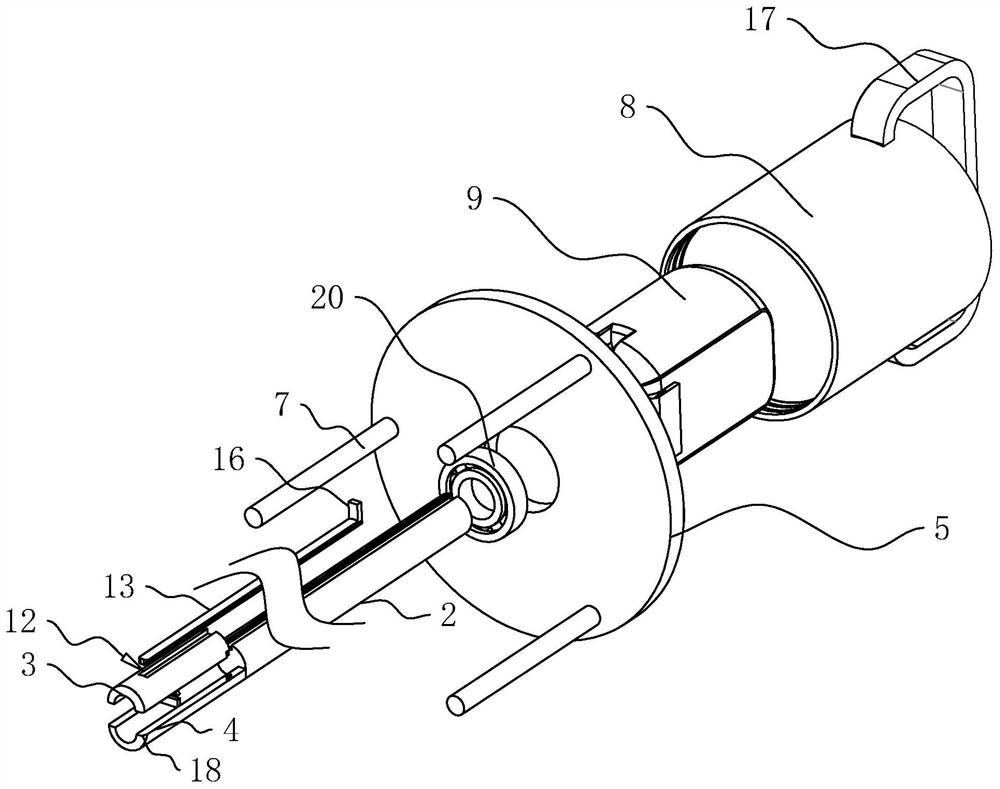

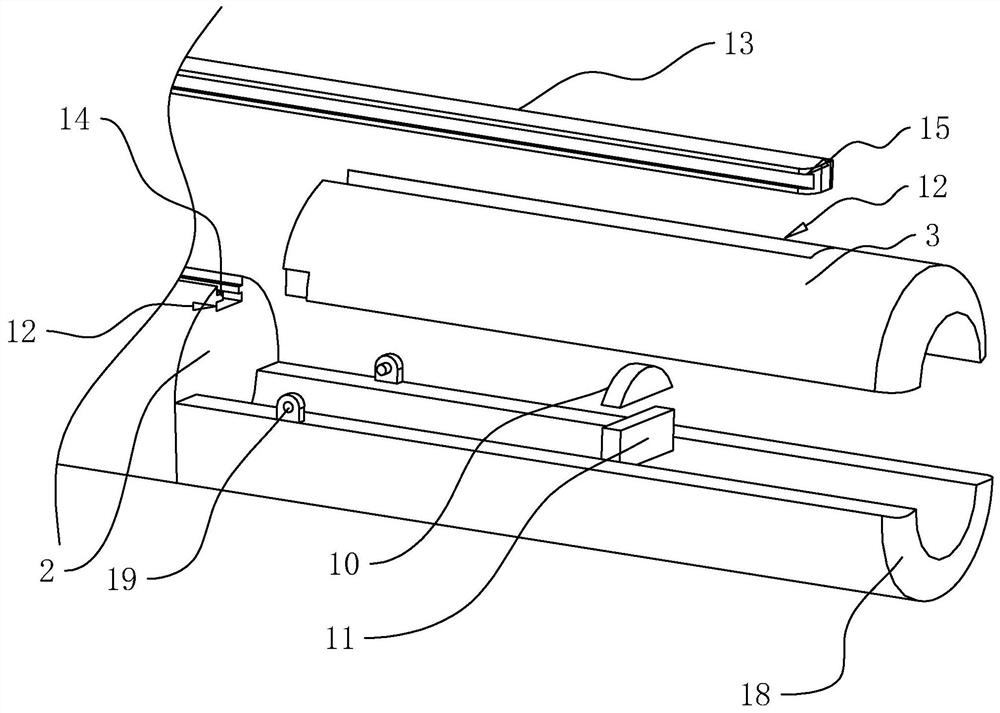

[0031] The following is attached Figure 1-2 The application is described in further detail.

[0032] The embodiment of the present application discloses a threading device of an extruder. refer to figure 1 , including a wire insertion tube 2 for passing through the die head 1, a fixing mechanism fixed at one end of the wire insertion tube 2 for fixing the wire insertion tube 2 on the die head 1, and a mechanism for driving the wire insertion tube 2 to rotate The rotating mechanism and the clamping mechanism arranged at the end of the wire insertion tube 2 away from the fixing mechanism are used for fixing a plurality of wires. When working, the staff inserts the wire insertion tube 2 from the discharge end of the die head 1 to the feed end of the die head 1, and fixes the wire insertion tube 2 on the die head 1 through a fixing mechanism, and then the staff inserts a plurality of wires The silk thread is fixedly arranged on the thread insertion tube 2, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com