Multi-hob system for slitting and rewinding belt

A technology of slitting, rewinding, and belts, which is applied in the field of multi-hob systems, can solve problems such as low verticality, slope of belt edges, and easy damage to blades, and achieve the goal of ensuring accuracy, ensuring fluency, and improving cutting accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

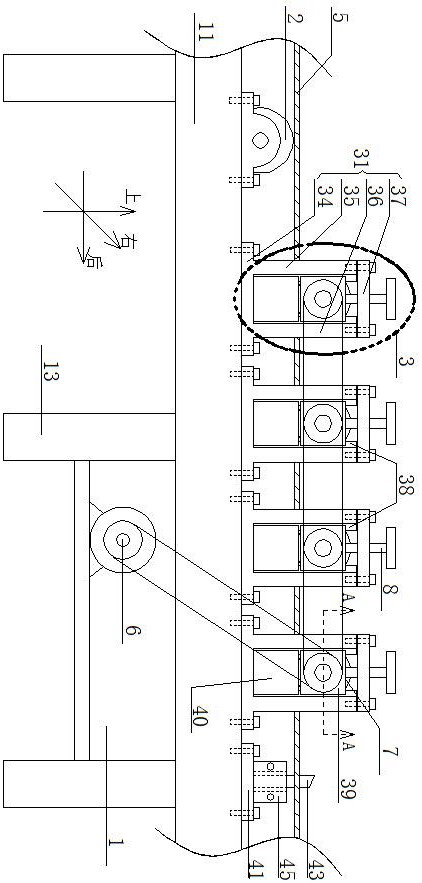

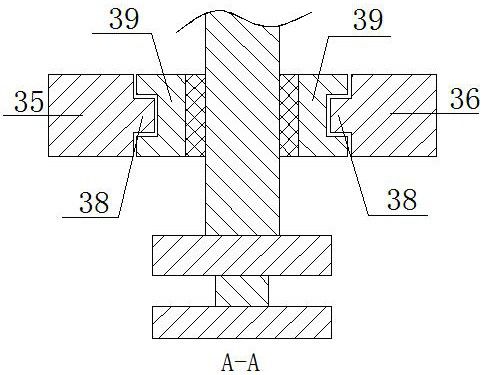

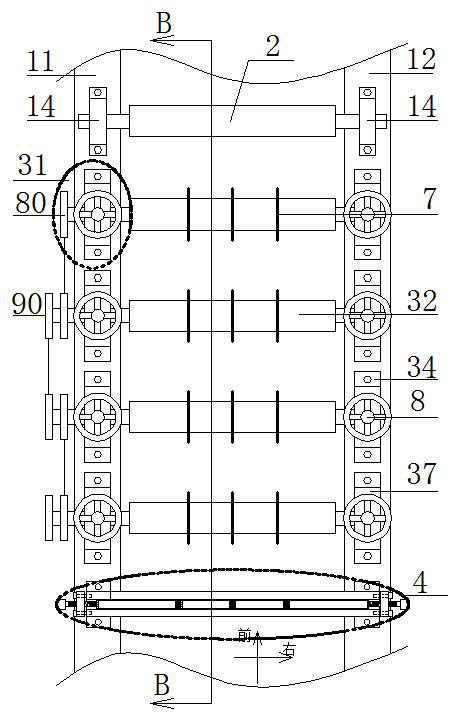

[0038] Embodiment 1: as Figure 1 to Figure 7The shown multi-hob system for belt slitting and rewinding includes a support table 1, which is composed of a left beam 11, a right beam 12, and a support leg 13, and the left beam 11 and the right beam 12 are from front to Afterwards, a guide roller 2, a plurality of longitudinal cutting devices 3 and a transverse cutting device 4 arranged side by side are provided in sequence. The thickness of the downward cutting of the belt 5 is gradually deepened to form a "progressive and step-by-step" longitudinal cutting mode, and then the transverse cutting is performed through the transverse cutting device 4, and the longitudinal cutting device 3 is synchronized by the drive motor 6 under the support table 1 Drive; the longitudinal cutting device 3 includes a base frame 31, a circular knife roller 32, and a support roll 33, and is located on the left side beam 11 and the right side beam 12, and two base frames 31 are arranged symmetrically...

Embodiment 2

[0045] Embodiment 2: when the thickness of belt 5 is 5mm, when requiring four equal parts to cut, as image 3 As shown, three round blades 7 are selected, three vertical blades 43 are selected, and four sets of longitudinal cutting devices 3 and one set of horizontal cutting devices 4 are used at the same time, that is, there are four sets of circular blades and one set of vertical blades, from front to back. It is the first group of round knives, the second group of round knives, the third group of round knives, the fourth group of round knives, and the vertical knives. Carry out "progressive and step-by-step" cutting of the belt 5 without cutting through the bottom of the belt 5. During the process, the first set of circular knives cuts downward to a depth of 1mm, and the second set of circular knives continues to cut downward to a depth of 1mm. The three sets of round knives continue to cut down to a depth of 1mm, and the fourth set of round knives continue to cut down to a...

Embodiment 3

[0046] Embodiment 3: When the belt is 4.5mm, and it is required to cut five parts (including three equal parts and two equal parts), as Figure 7 As shown, four circular blades 7 are selected, four vertical blades 43 are selected, and four sets of longitudinal cutting devices 3 and one set of horizontal cutting devices 4 are used at the same time, that is, there are four sets of circular blades and one set of vertical blades, from front to back. It is the first group of round knives, the second group of round knives, the third group of round knives, the fourth group of round knives, and the vertical knives. Carry out "progressive and step-by-step" cutting of the belt 5 without cutting through the bottom of the belt 5. During the process, the first set of circular knives cuts downward to a depth of 1mm, and the second set of circular knives continues to cut downward to a depth of 1mm. The three sets of round knives continue to cut down to a depth of 1mm, and the fourth set of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com