Scaffold anti-skid platform

A scaffolding and anti-slip technology, which is applied in the field of scaffolding, can solve the problems of unresolved safety hazards, safety hazards, and poor anti-slip performance of the scaffolding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

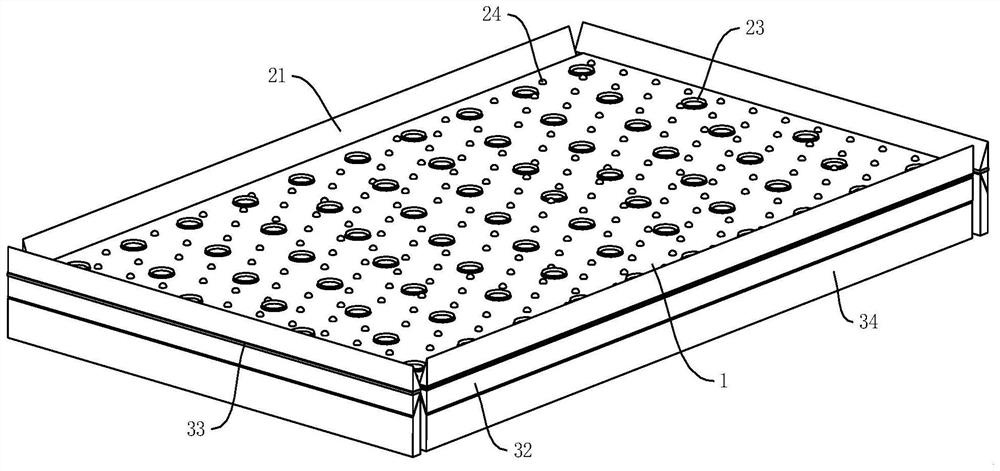

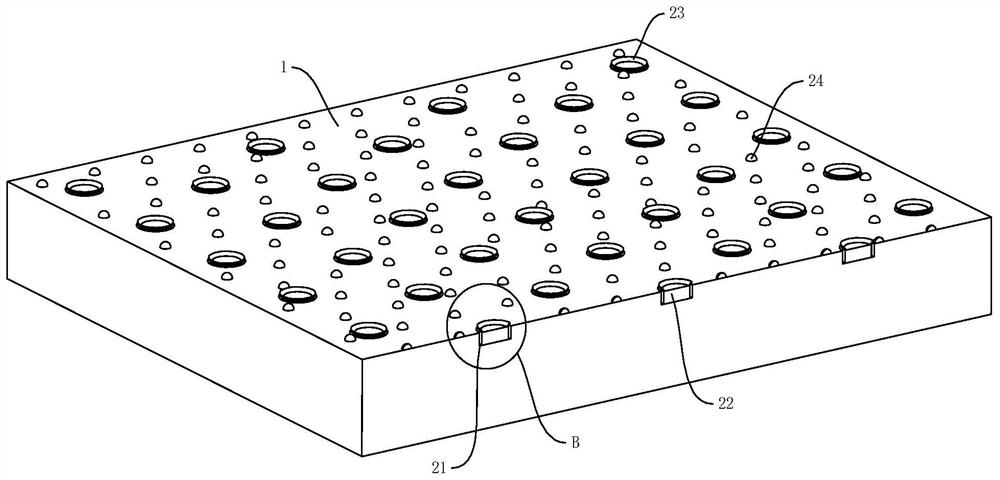

[0021] It includes a platform 1 installed on the support rod of the scaffolding. The upper surface of the platform 1 is provided with an anti-slip structure. The anti-slip structure includes a buffer groove 21, a buffer tube 22 and an anti-slip end piece 23. The buffer groove 21 is evenly opened on the platform 1. The upper surface of the buffer tube 22 is set in the inner cavity of the buffer tank 21, and the anti-slip end piece 23 is installed on the end of the buffer tube 22 away from the bottom of the buffer tank 21, and at least one of the buffer tube 22 and the anti-slip end piece 23 has a recoverable deformation The anti-slip end piece 23 is made of elastic material, the inside of the anti-slip end piece 23 is hollow and the diameter of its upper end is greater than the diameter of the lower end; the staff steps on the platen 1 to squeeze the anti-slip end piece 23, and the anti-slip end piece 23 is passively squeezed and The buffer tubes 22 are squeezed relative to each...

Embodiment 2

[0023] Embodiment 2, the difference between this embodiment and Embodiment 1 is that a protective encirclement is formed on the outside of the platen 1:

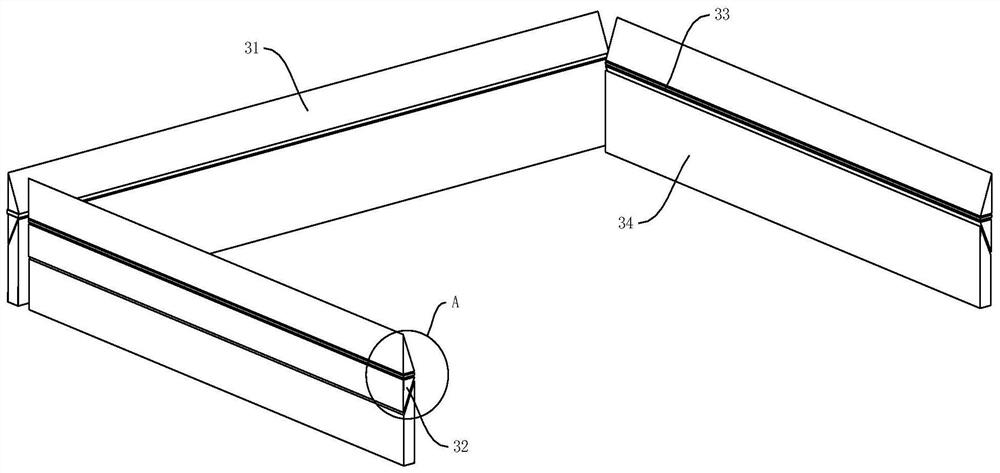

[0024] A peripheral plate 1 31 and a peripheral plate 2 32 are installed on the outer surface of the platen 1, the peripheral plate 1 31 and the peripheral plate 2 32 are arranged oppositely and form an encircling circle on the outside of the platen 1; the enclosing circle forms an anti-slip ring on the outside of the platen 1 , to prevent the staff or materials from directly sliding out of the surface of the table 1 through the outside of the table 1, which effectively hinders, buffers and protects the sliding process, and has higher safety.

[0025] Peripheral plate 1 31 and peripheral plate 2 32 are relatively triangular, and the components of triangular peripheral plate 1 31 and peripheral plate 2 32 are inclined outwardly along the side away from platen 1, and the periphery of the triangular structure Board 1 31 and per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com