Automatic cloth cutting system

A cloth cutting technology, applied in the field of cloth slitting equipment, can solve problems such as difficult to adapt to processing requirements, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

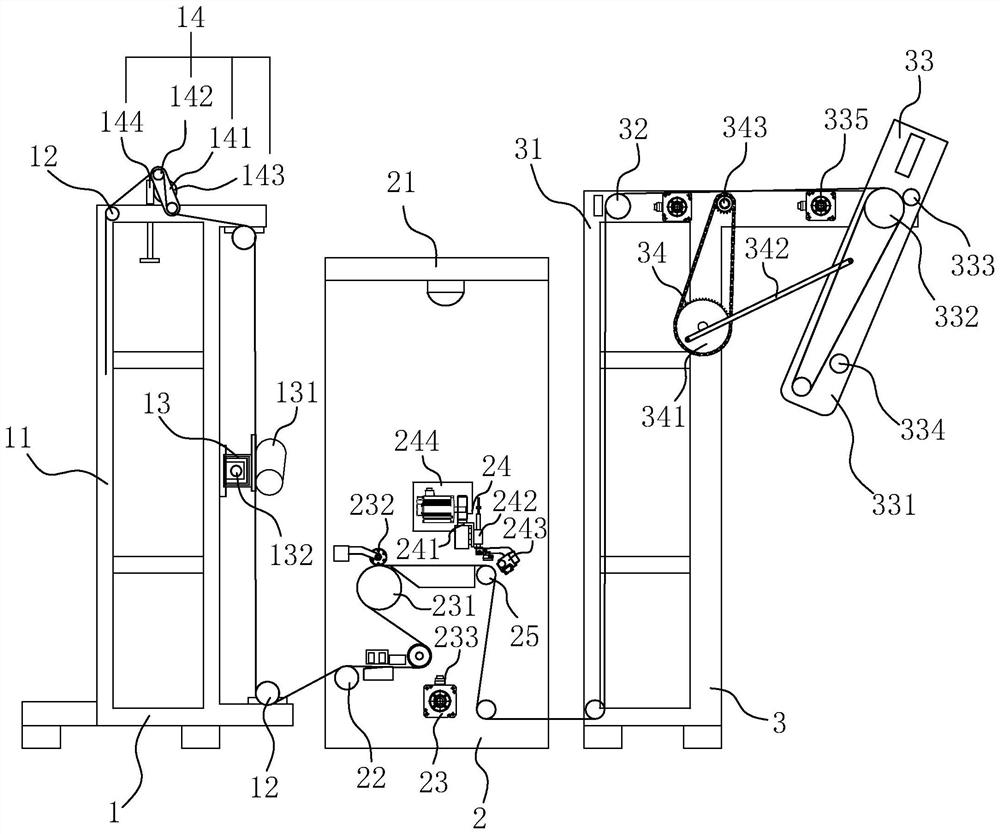

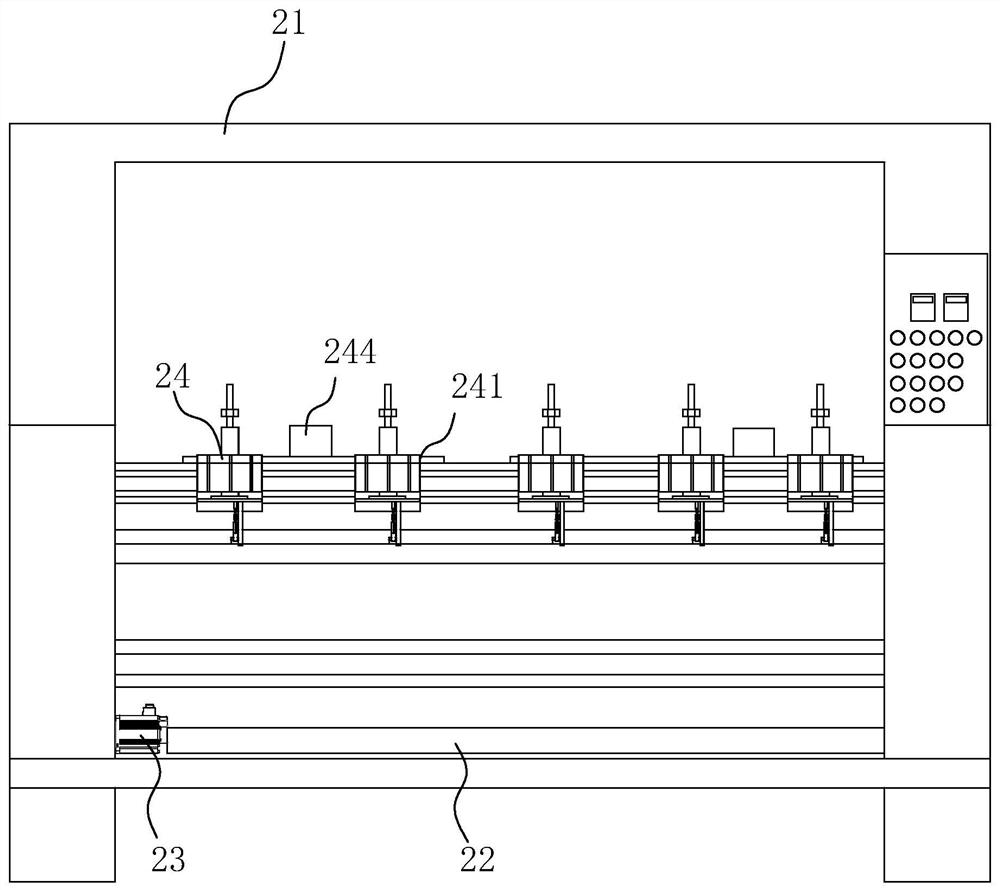

[0041] An automated cloth cutting system, such as Figure 1 to Figure 4 As shown, it includes: a cloth conveying device 1 , a cloth cutting device 2 , and a cloth collecting device 3 arranged in sequence.

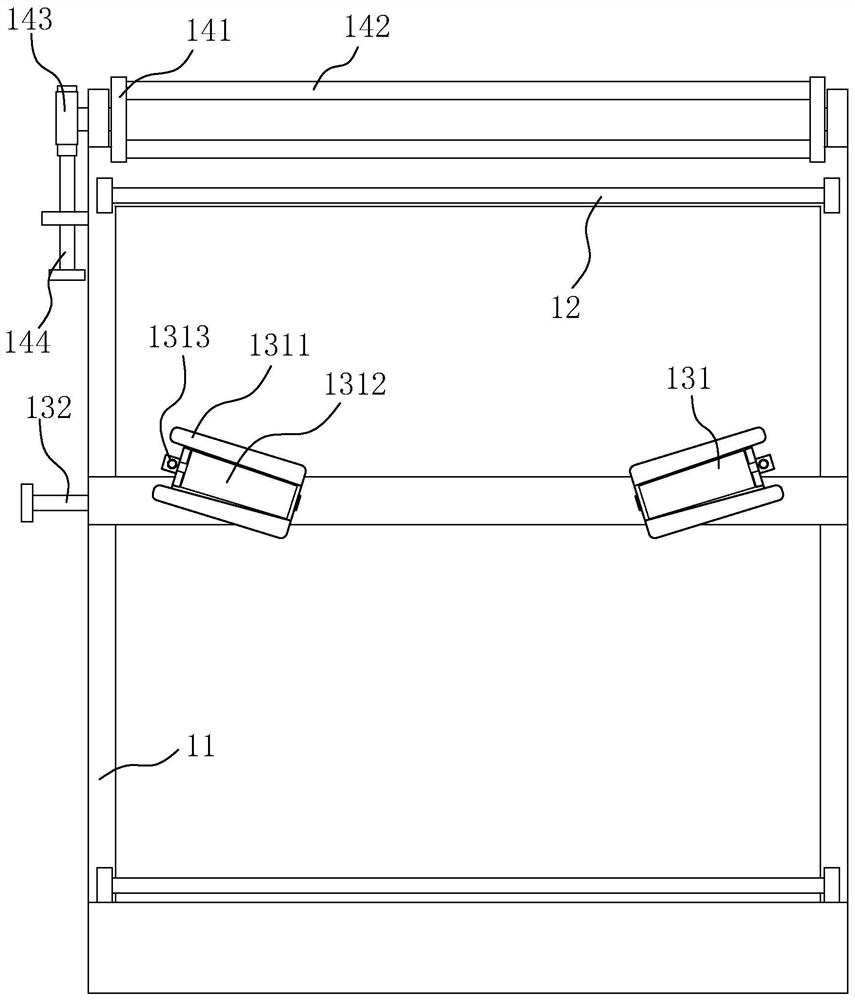

[0042] Specifically, the cloth conveying device 1 includes: a cloth feeding frame 11 , several cloth guide rods 12 carried on the cloth feeding frame 11 , and a cloth spreading mechanism 13 carried on the cloth feeding frame 11 for spreading the cloth.

[0043] The cloth spreading mechanism 13 includes: two groups of force application assemblies 131 that are arranged oppositely and are slidably mounted on the cloth feed frame 11 for applying outward pulling force on both sides of the cloth, and are rotatably mounted on the cloth feed frame 11 for driving the two cloth applicators. The force component 131 is relatively close to or away from the adjusting screw 132, and the force component 131 includes: a cloth clamping seat 1311 that is slidably assembled on the cloth feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com