A manual disconnecting and connecting device

A disconnection and integration technology, which is applied in the field of manual disconnection and connection devices, can solve problems such as failure to realize remote control and data Internet transmission, strong dependence on manual operation, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

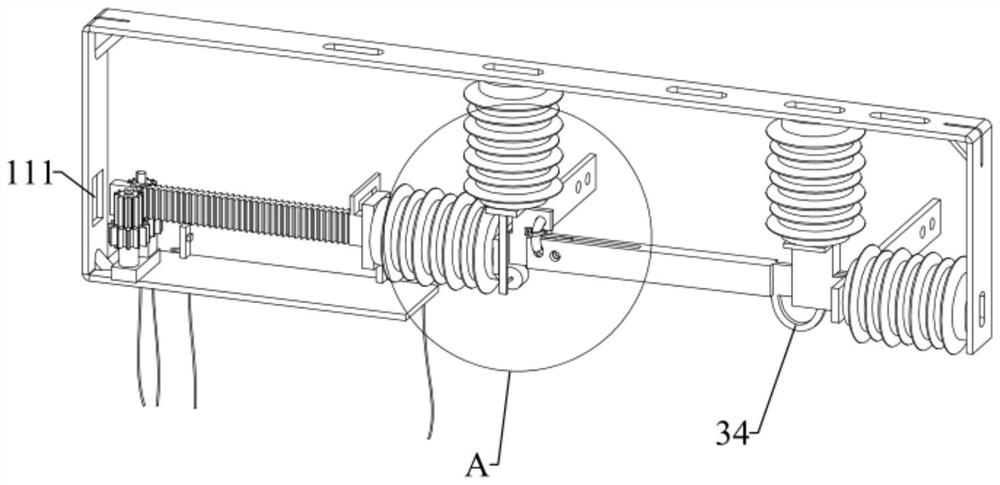

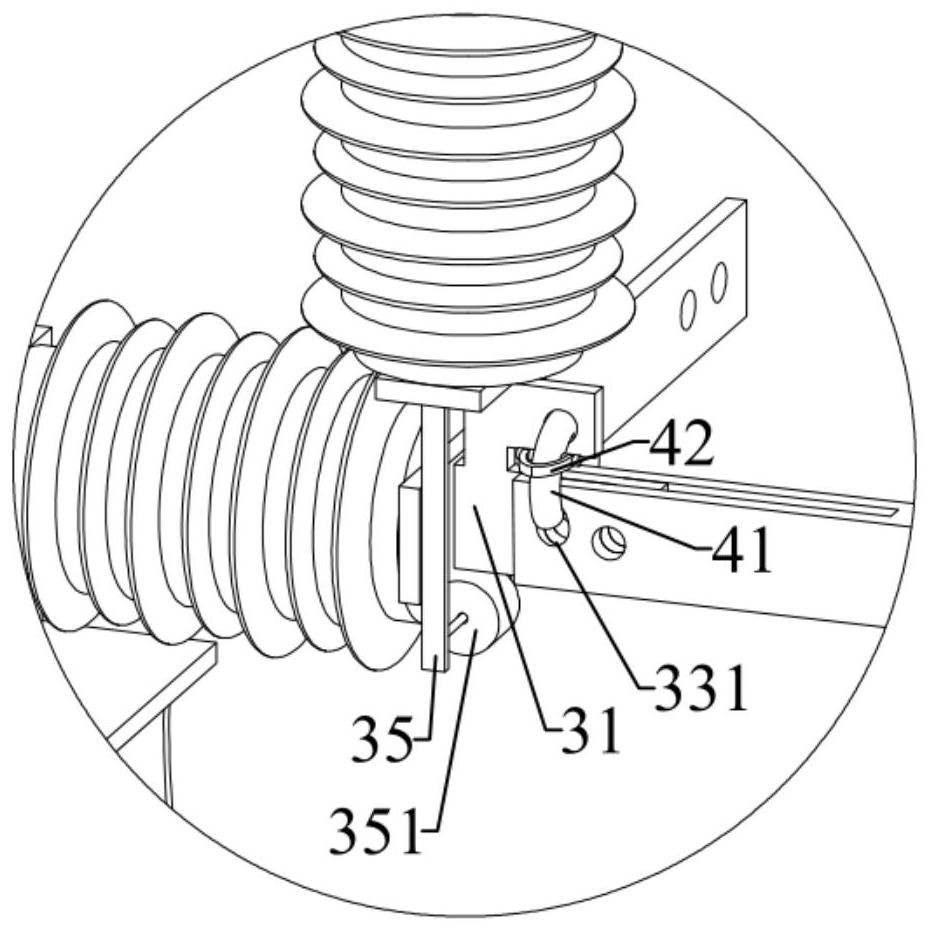

[0033] Such as Figure 1-Figure 3 As shown, the present invention provides a manual disconnecting and connecting device, including a bracket 1, a driving mechanism 2, an opening and closing mechanism 3 and a switching mechanism 4. The bracket 1 includes two vertical frames 11 and a horizontal frame 12, and the two vertical frames The frame 11 is installed on both ends of the horizontal frame 12; the driving mechanism 2 is fixedly installed on one of the vertical frames 11; the opening and closing mechanism 3 includes a first terminal 31, a second terminal 32 and a knife 33, the first terminal 31 Installed on the driving mechanism 2, the second terminal 32 is fixedly installed on the other vertical frame 11, the switch blade 33 is provided with a switching hole 331, one end of the switch blade 33 is rotatably connected to the first terminal 31, and the other end is engaged in the second terminal 32; when the switching mechanism 4 is engaged in the switching hole 331, one end of...

Embodiment 2

[0044] This embodiment provides a manual disconnecting and connecting device, which is further improved on the basis of Embodiment 1. The driving mechanism 2 also includes two sensors 26 and an induction frame 27. The movement of the two sensors 26 along the rack 23 The directions are set on the supporting frame 21 at intervals, and the induction frame 27 is fixedly installed on the rack 23. When the rack 23 drives the induction frame 27 to move, the induction frame 27 can trigger the sensor 26, so that the operator can know the opening and closing of the switch knife 3 state, when the induction frame 27 triggers the sensor 26 near the second terminal 32 side, the sensor 26 sends a signal to the control device, and the control device controls the indicating device (such as an indicator light) to indicate that the switch knife 3 is in a closed state, and the induction frame 27 triggers When away from the sensor 26 on the side of the second terminal 32, the sensor 26 sends a sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com