Full-automatic pressure gauge verification table and full-automatic verification method

A pressure gauge, fully automatic technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of failing to significantly reduce the workload of pressure gauge verification by measurers, so as to improve detection efficiency and accuracy, improve Intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

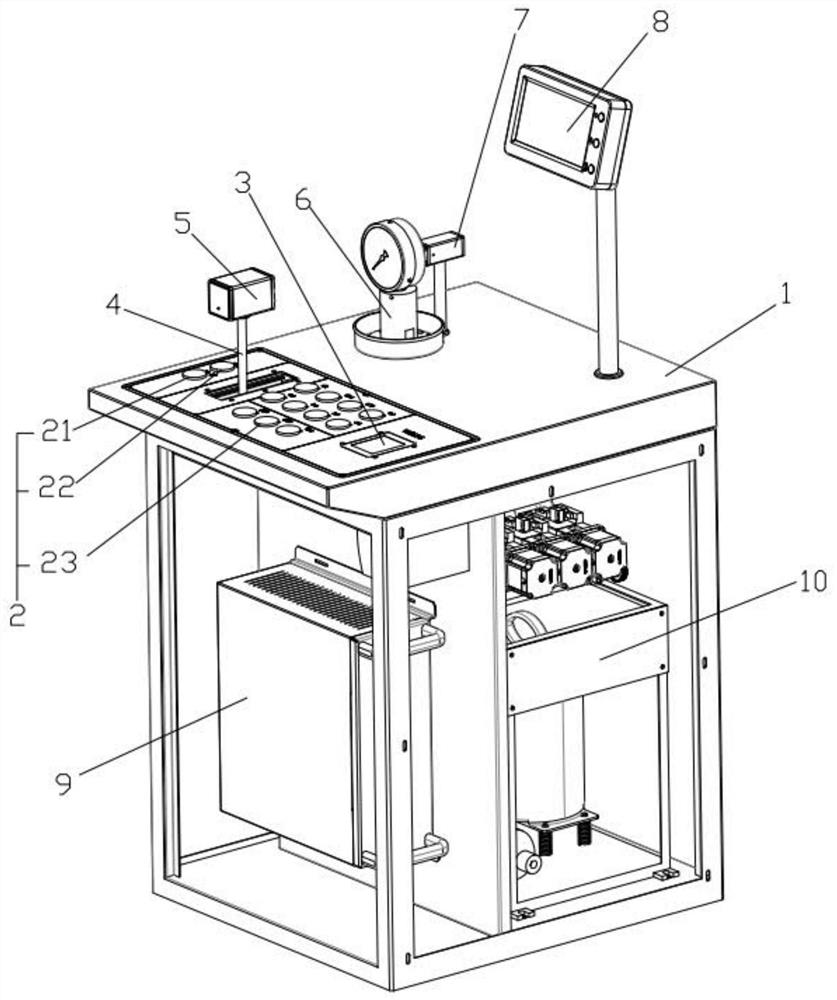

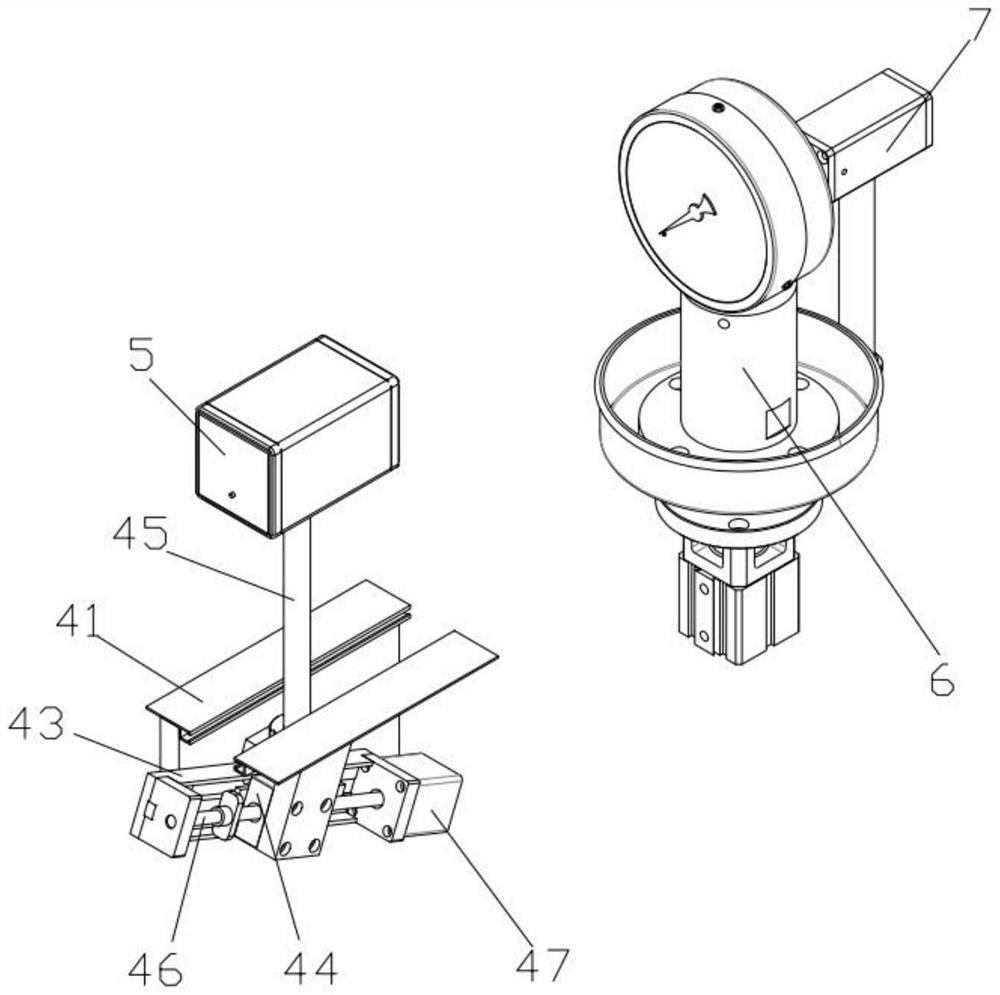

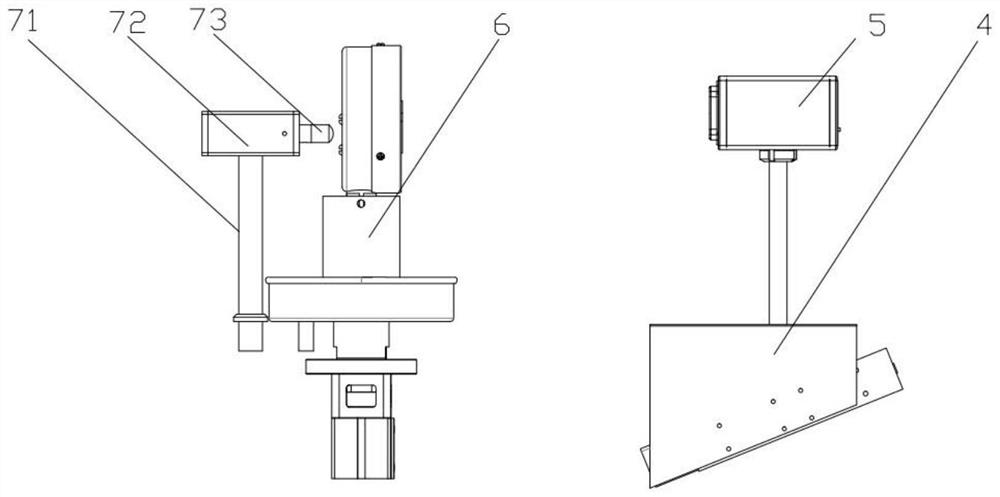

[0066] Such as Figures 1 to 3 As shown, a pressure gauge full-automatic testing platform includes a testing platform 1, a switch 2, a code scanning device 3, a camera adjusting mechanism 4, a camera 5, a clamping mechanism 6, a knocking mechanism 7, a display 8, a controller 9 and a gas Road control system 10; the camera adjustment mechanism 4 includes a sliding base 43 and a slide block 44, the slide block 44 is slidingly matched with the sliding base 43, the sliding base 43 is inclined, and the camera 5 is installed on the slide block 44 and faces the clamping mechanism 6. The table knocking mechanism 7 includes a vertical rod 71, a telescopic cylinder 72 and a push rod 73, the push rod 73 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com