Fire-extinguishing bottle simulation device and method

A simulation device and technology of fire extinguishing bottle, applied in the field of fire extinguishing and explosion suppression, can solve the problem of disconnection of fire extinguishing pipeline, unable to truly reflect the detonation process of 1211 fire extinguishing bottle electric explosion tube, and unable to completely test the function of fire extinguishing and explosion suppression system and other problems to achieve the effect of high simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

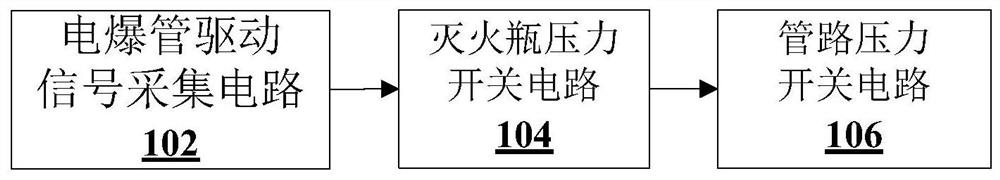

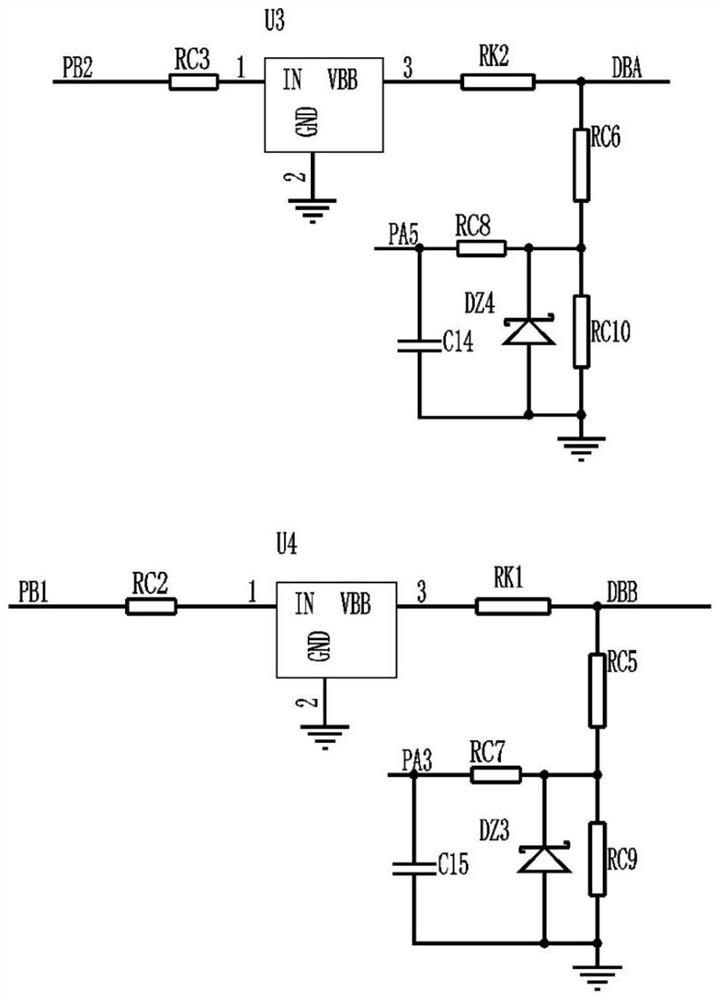

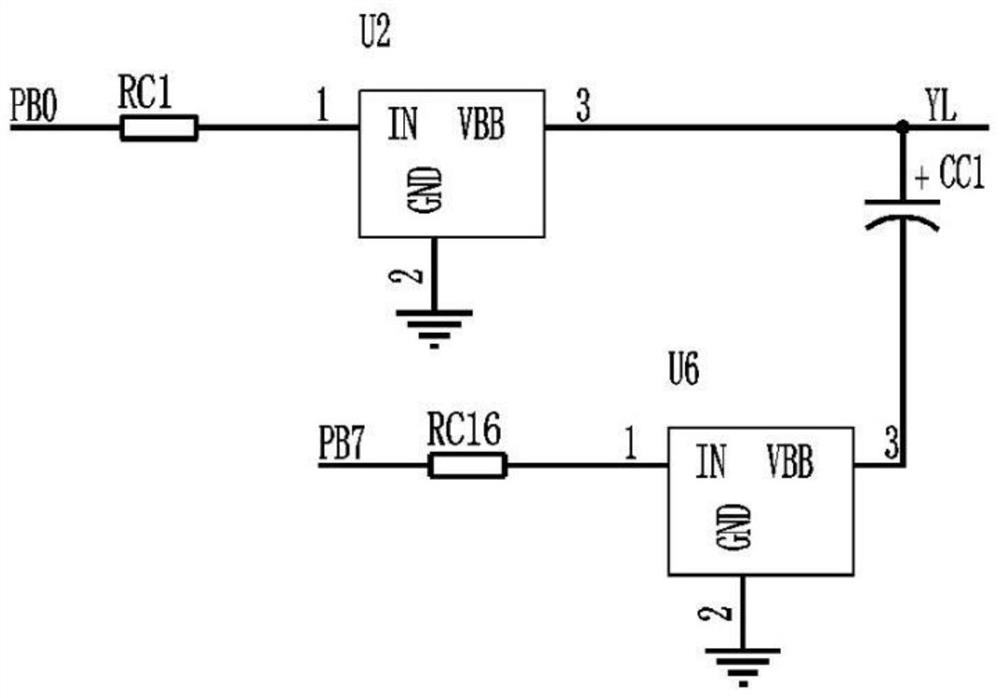

[0033] A specific embodiment of the present invention discloses a fire extinguisher simulation device. refer to figure 1 , the fire extinguisher simulation device includes: electric squib drive signal acquisition circuit 102, used for simulating the circuit of starting the fire extinguisher electric squib according to the start time of the electric squib when the fire suppression system sends out a fire alarm; fire extinguisher pressure switch circuit 104, used At the first preset time after the electric squib is started, the circuit that simulates the disconnection of the fire extinguisher pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com