Rotor balancing method and apparatus

A technology of rotor balancing and rotor, which is used in measuring devices, static/dynamic balance testing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present disclosure relates to methods for balancing rotors used in turbomachines, such as gas turbines.

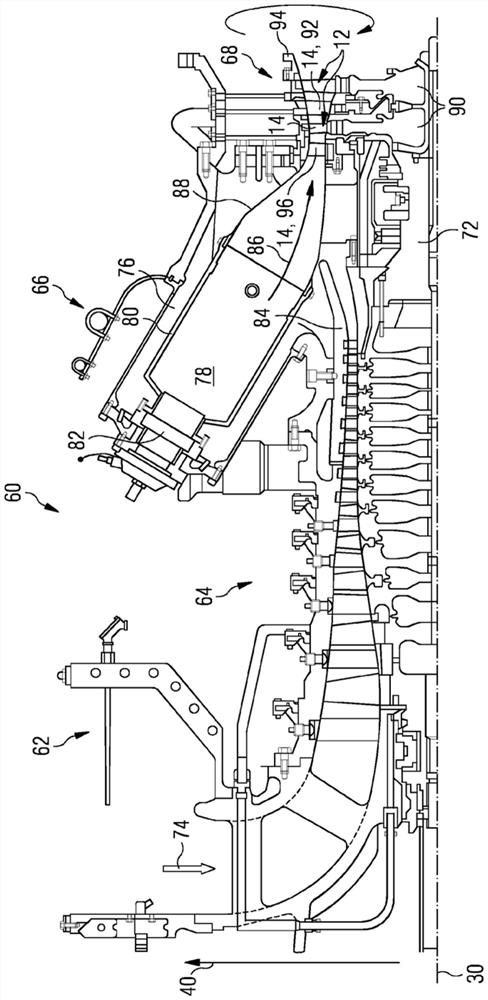

[0031] by context, figure 1 A known arrangement is shown in which the features of the present disclosure may be applied.

[0032] figure 1 One example of a gas turbine engine 60 is shown in a cross-sectional view illustrating the nature of the rotor and the environment in which the rotor operates. Gas turbine engine 60 includes an intake 62 , a compressor section 64 , a combustion section 66 , and a turbine section 68 in a flow order generally arranged in flow order and generally in the direction of the longitudinal or rotational axis 30 . Gas turbine engine 60 also includes a rotor shaft 72 rotatable about axis of rotation 30 and extending longitudinally through gas turbine engine 60 . The axis of rotation 30 is generally the axis of rotation of the associated gas turbine engine. Accordingly, any references to “axial”, “radial” and “circumferential” directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com