An automatic weighing packaging machine

An automatic and heavy-packing technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of large weighing errors of materials that are easy to stick to the wall, and achieve the effects of saving labor costs, adding materials smoothly, and improving packaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

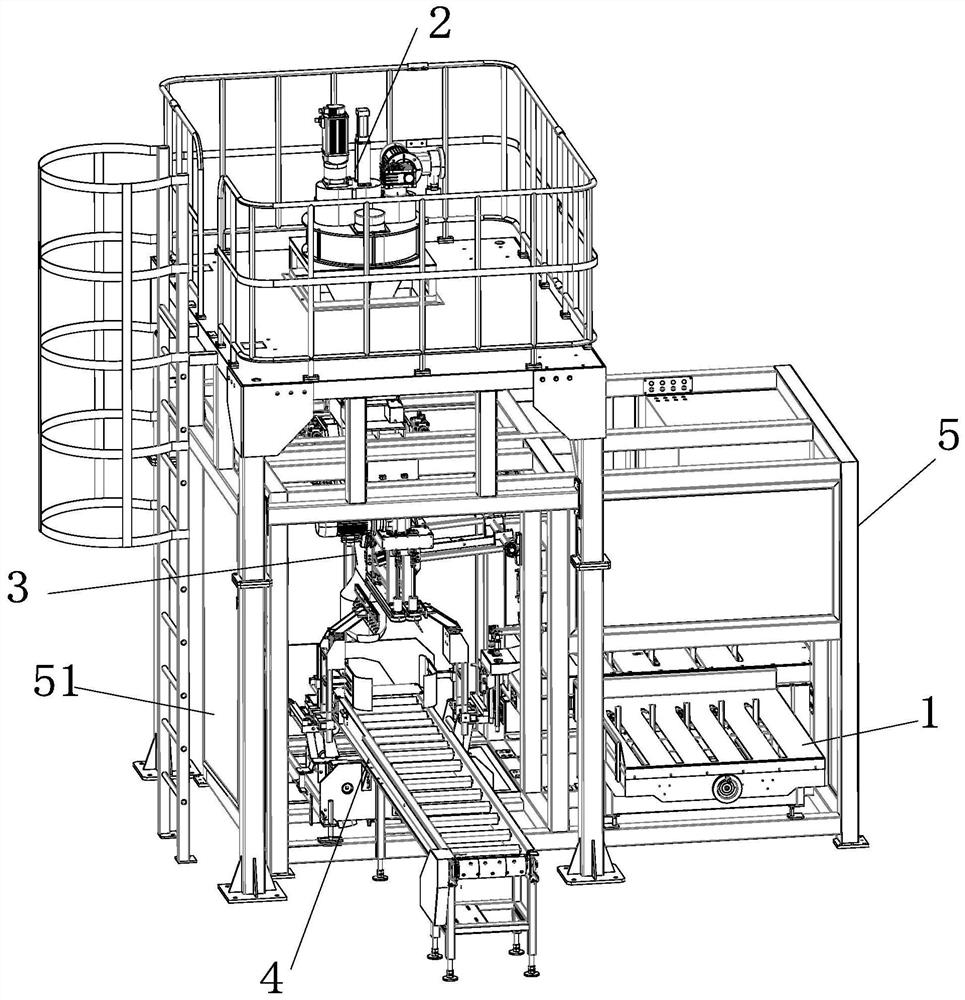

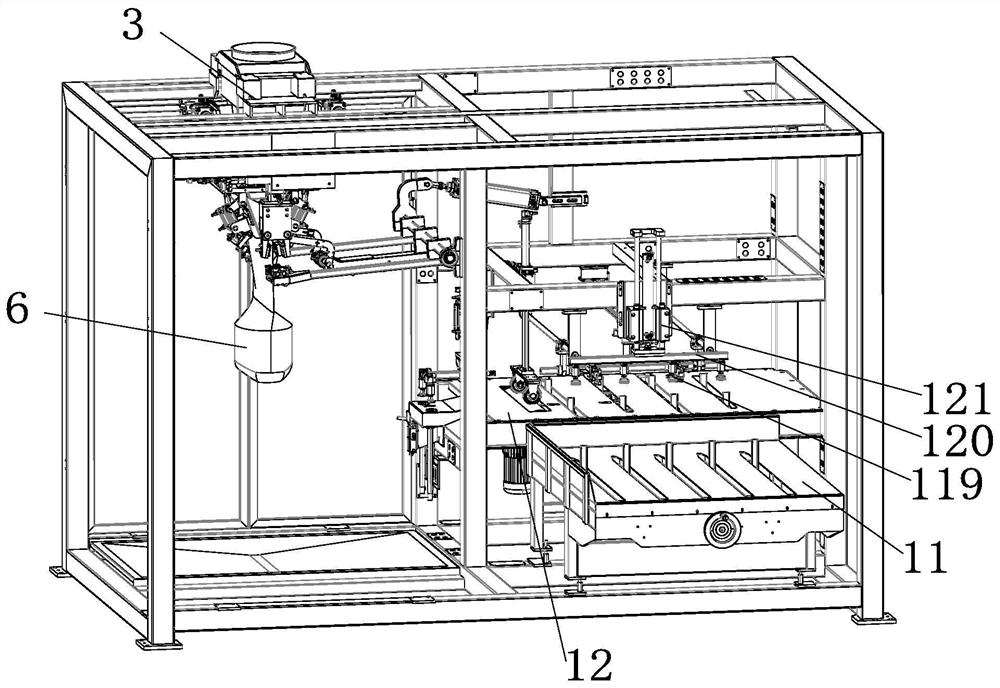

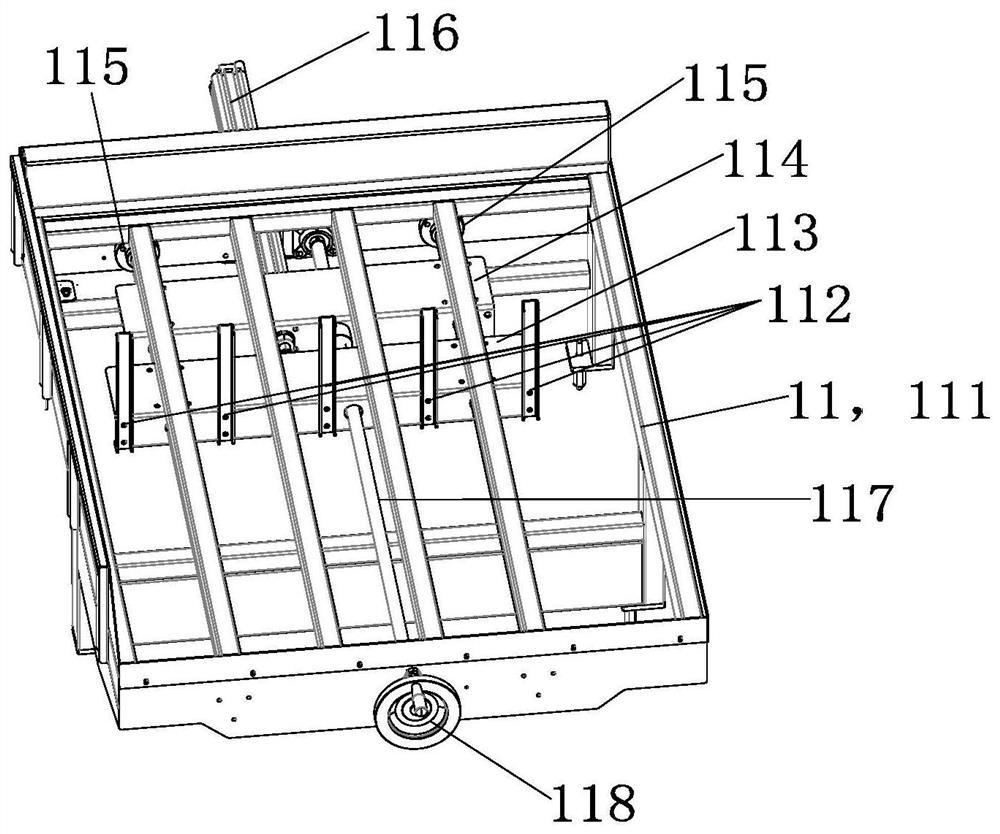

[0055] Embodiment: a kind of automatic weighing packaging machine, as attached figure 1 As shown, the weighing packaging machine includes an automatic bagging mechanism 1, a bag clamping mechanism 3, a vertical feeding mechanism 2 and a bag pushing mechanism 4; in this embodiment, an automatic bagging mechanism 1, a bag clamping mechanism 3, a vertical feeding mechanism 2 and a pushing The bag mechanism 4 is integrated and installed on the frame structure 5, and a U-shaped installation space is formed in the frame structure 5, wherein the automatic bag-loading mechanism 1 and the bag-pushing mechanism 4 are arranged in parallel, and the bag-clamping mechanism 3 is located on the front side of the automatic bag-loading mechanism 1 Above, and be positioned at the top of pushing bag mechanism 4, vertical feeding mechanism 2 is positioned at the top of bag clamping mechanism 3, and the outer frame of frame structure 5 is all equipped with environmental protection frame 51 all aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com