20-ton super-tonnage freight elevator

A super tonnage, elevator technology, applied in elevators, sustainable buildings, elevators and other directions in buildings, can solve the problem of reducing elevator carrying stability and safety, elevator stability and safety cannot be guaranteed, reducing elevator carrying stability and other problems, to achieve the effect of improving carrying stability and safety, improving carrying stability, and avoiding tilting or swaying from side to side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

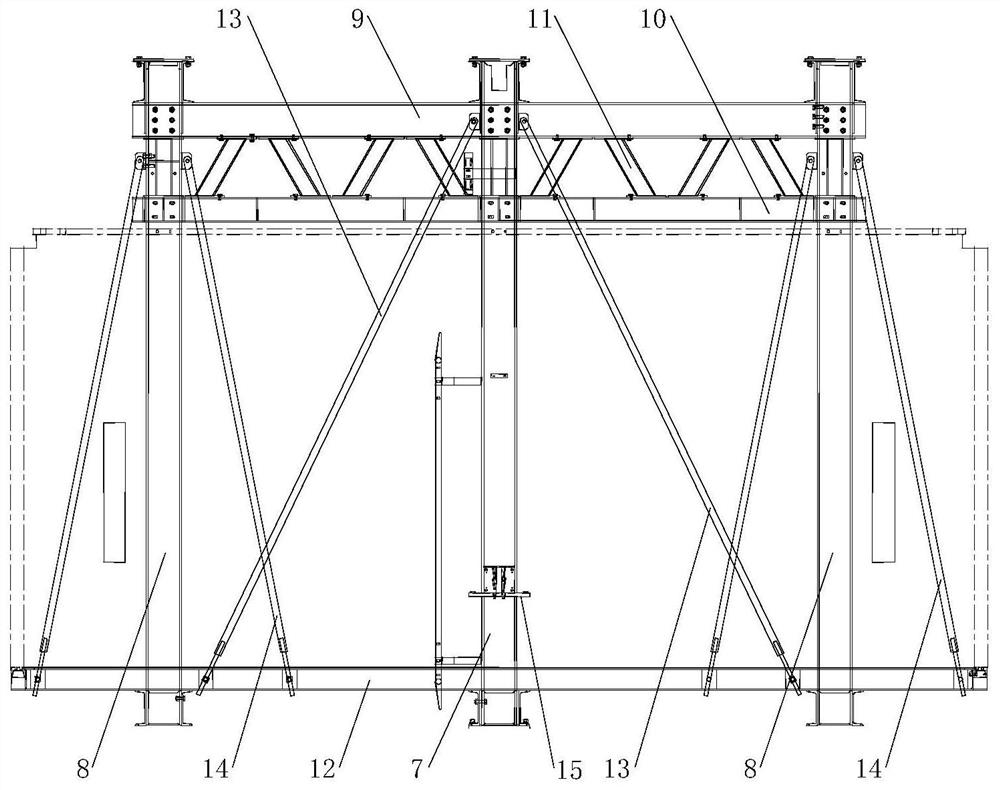

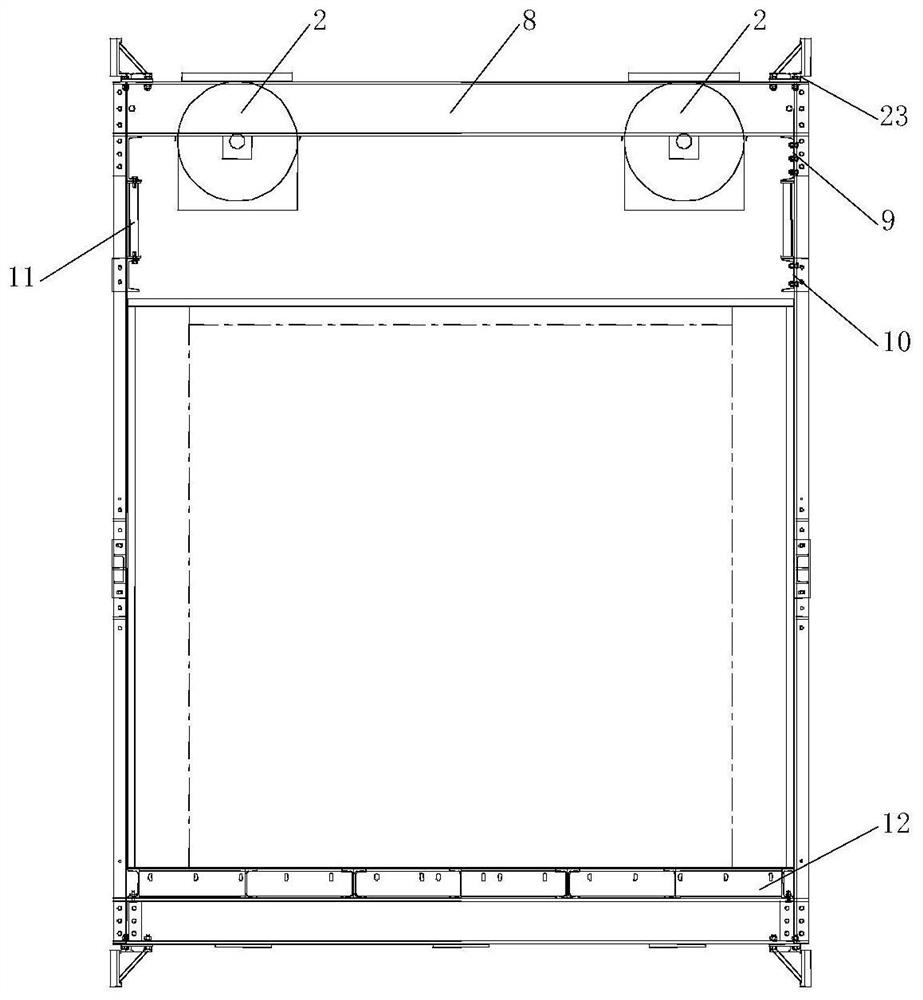

[0040]Examples. The 20-ton super large tonnage freight elevator is composed asfigure 1 Shown (figure 1 The two cars 1 in the same car 1 are the left and right sides of the same car 1), including car 1, with a car frame on the outside of the car 1, and two sets of car reverse sheaves on both sides of the car frame. The car reversing sheave group includes two car reversing sheaves 2 arranged side by side. The car reversing sheave 2 is provided with a traction wire rope 3, which passes through the two groups of reversing sheaves and is connected in turn The hoisting machine 4 and the counterweight device 5 are provided with four counterweight anti-sheaves 6 matched with the traction wire rope 3 on the counterweight device 5, and the suspension ratio of the elevator is 8:1.

[0041]The car frame includes a main straight beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com