A stucco mechanism for building decoration materials

A technology for building decoration materials and coatings, which is applied to devices and coatings that apply liquid to surfaces, can solve problems such as inability to achieve, thick paint thickness, dripping, etc., to improve utilization, uniform paint thickness, and prevent particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

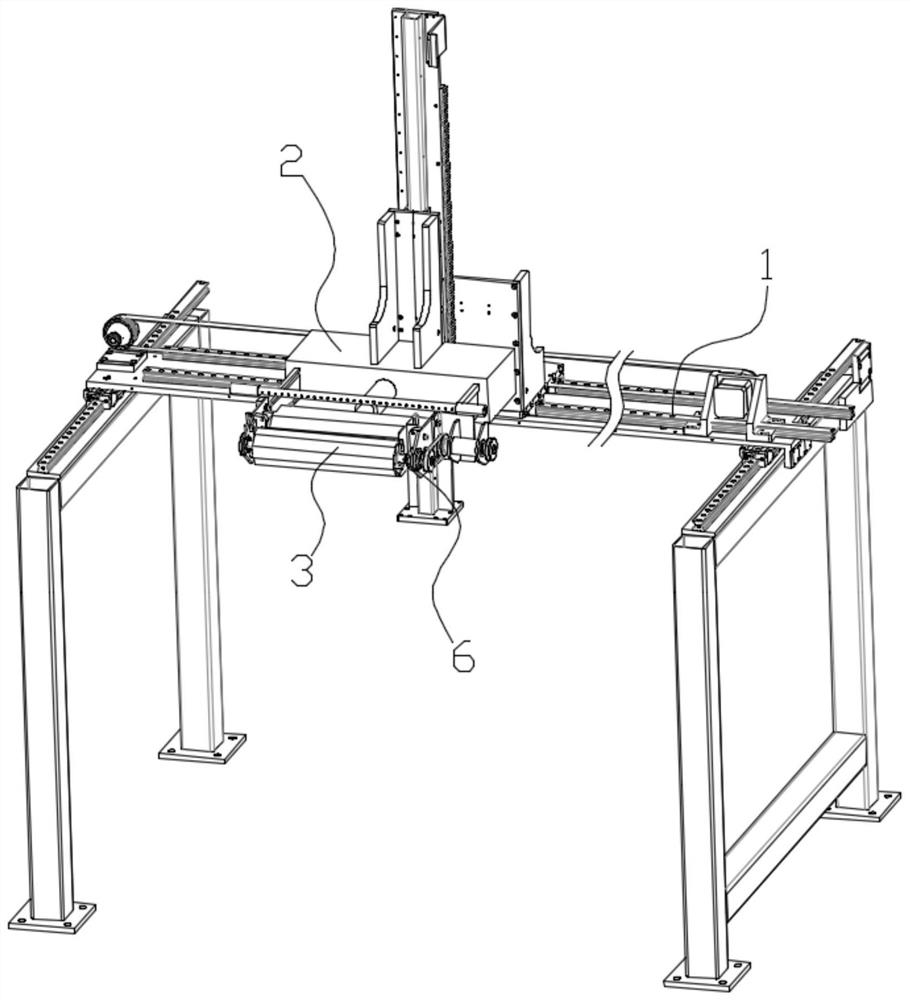

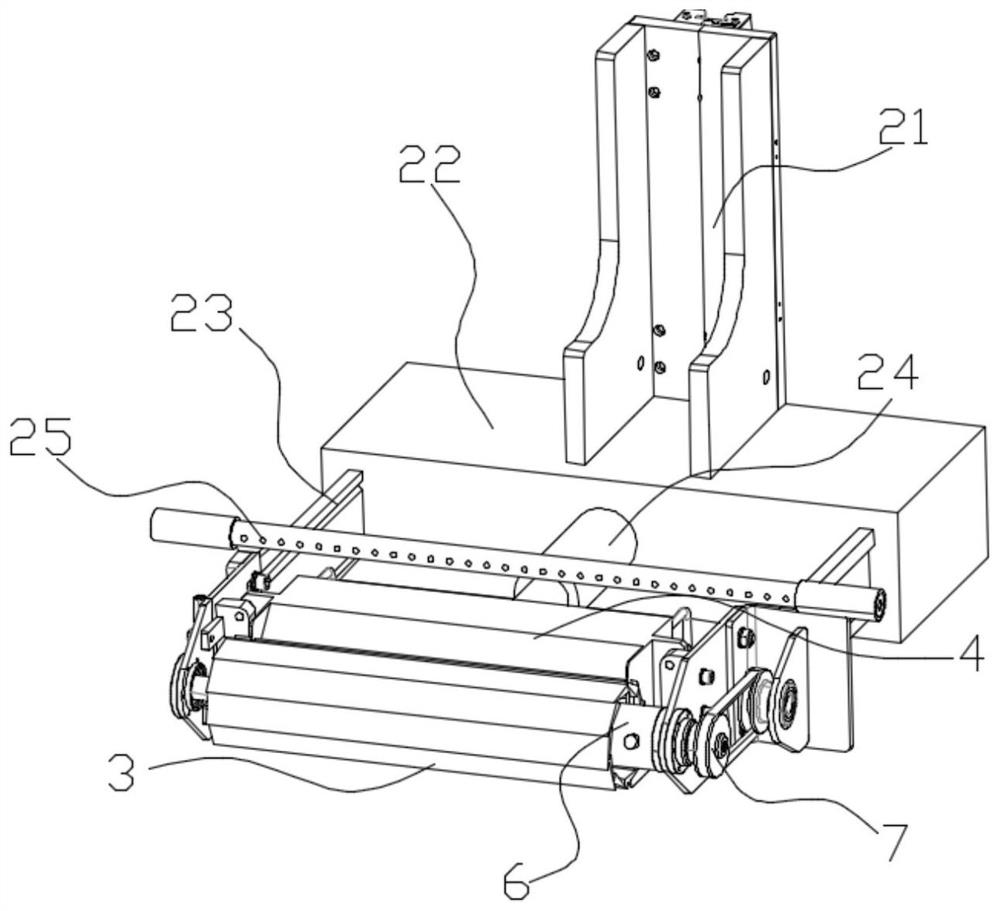

[0037] see figure 1 , in an embodiment of the present invention, a painting mechanism for building decoration materials includes a three-axis mobile platform 1, a telescopic support 2, a brush roller 3 and a liquid distribution assembly 6, wherein the telescopic support 2 is arranged on a three-axis On the mobile platform 1, the three-axis mobile platform 1 has slideways in three directions: horizontal, up and down, and front and back, and the front and rear positions of the telescopic support 2 can be adjusted through the slideways, and its horizontal and up-down translation is controlled by motor drive, so that To automatically complete the painting action;

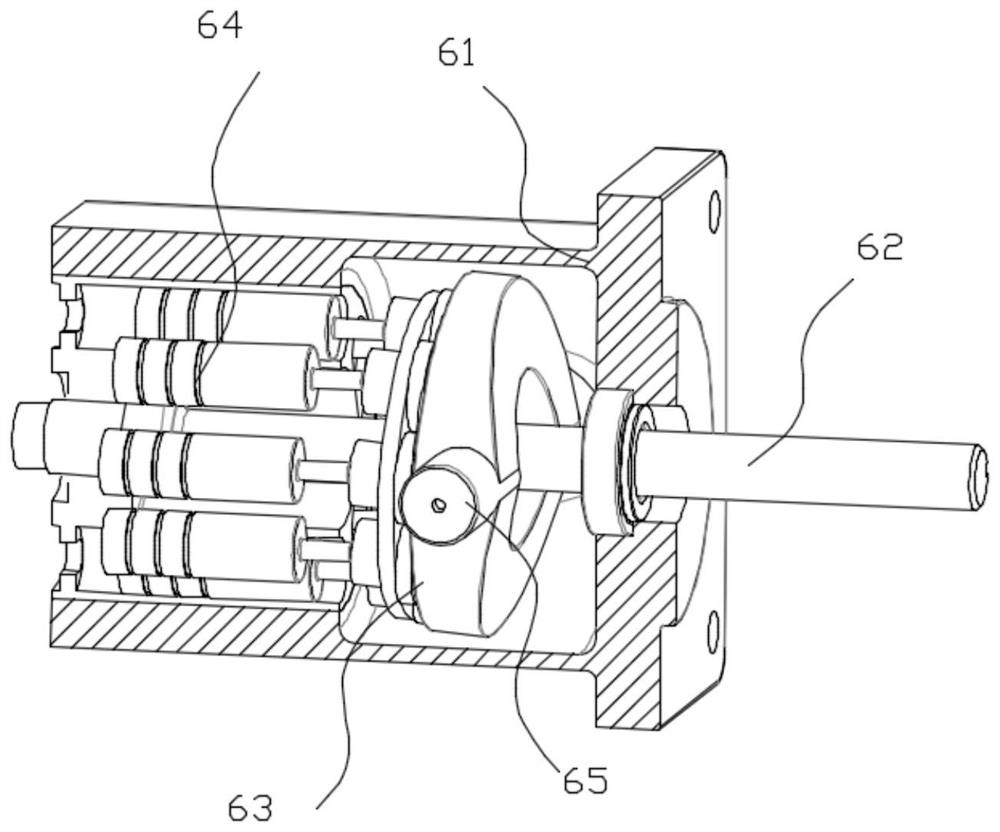

[0038] The telescopic bracket 2 can control the brush roller 3 to move back and forth, and the brush roller 3 conveys the paint to its interior through the external storage tank (not shown in the figure), and passes the liquid distribution assembly 6 along the hair The coating is injected in the circumferential directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com