Multi-cylinder diesel engine set

A technology for diesel generator sets and generator sets, which is applied to supporting machines, mechanical equipment, machines/supports, etc., can solve the problems of low buffer comprehensiveness, lack of buffer devices, and unfavorable use stability of diesel generator sets, so as to ensure effectiveness and convenience. comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

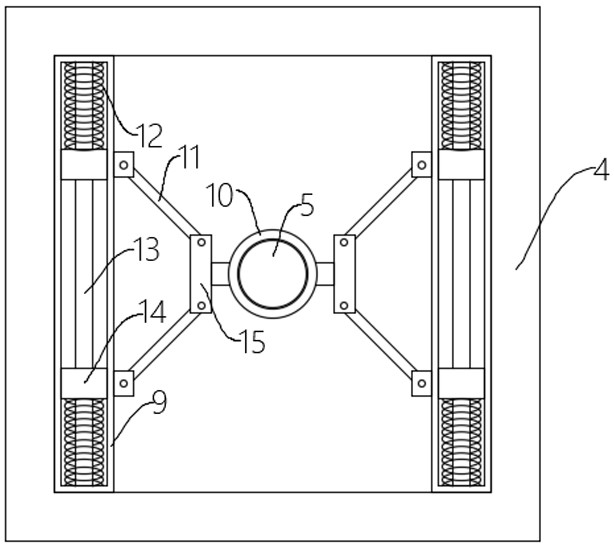

[0015] refer to Figure 1-2 , a multi-cylinder diesel unit, including a mounting base 3 and a unit 1, the lower end of the unit 1 is fixed with a mounting pad 2, the mounting pad 2 is fixed on the mounting base 3, and the lower end of the mounting base 3 is fixed with a plurality of fixing columns 6, each Each fixed column 6 is equipped with a fixed tube 8, the fixed tube 8 is fixed with a rubber buffer block 7, the fixed column 6 is located on the rubber buffer block 7, the lower end of the installation backing plate 2 is fixed with a movable column 5, and a plurality of fixed tubes 8 are jointly fixed with a buffer seat 4, and the movable column 5 passes through the mounting seat 3 and is provided with a sleeve 10 on a sliding sleeve. A buffer device is installed. The buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com