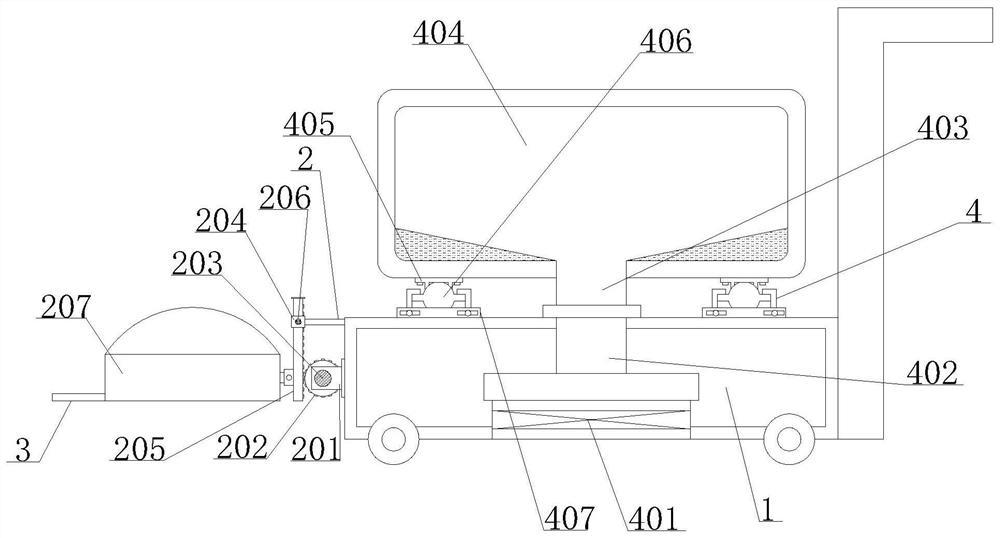

Hand-push type field weeding machine

A weeder, hand-push technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems that affect the performance and service life, easy to hit obstacles, and cannot be adjusted in height, so as to ensure the service life , broad development space, and the effect of diversified functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a horizontal plate is fixedly installed on the left side of the rack 205, and a limit rod is fixedly installed on the inner surface of the horizontal plate, and a connecting block is fixedly installed on the surface of the housing 207, and the housing 207 is movably connected in the position-limiting position through the connecting block. On the surface of the rod, the structure is set so that the casing 207 can be turned over after use, so as to facilitate cleaning and maintenance, and facilitate operation.

Embodiment 2

[0038] In Embodiment 2, the inside of the temporary storage box 404 is fixedly equipped with an oblique stopper, and when the temporary storage box 404 is full, it is disassembled, and the weeds can be poured out smoothly without leaving behind, and the practicability is high.

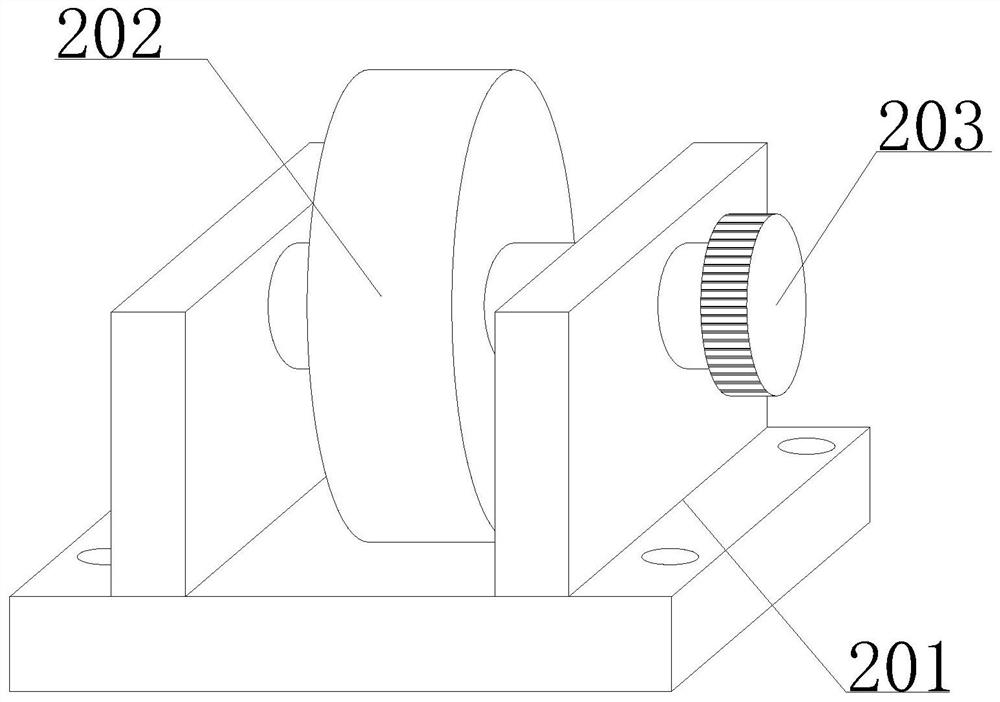

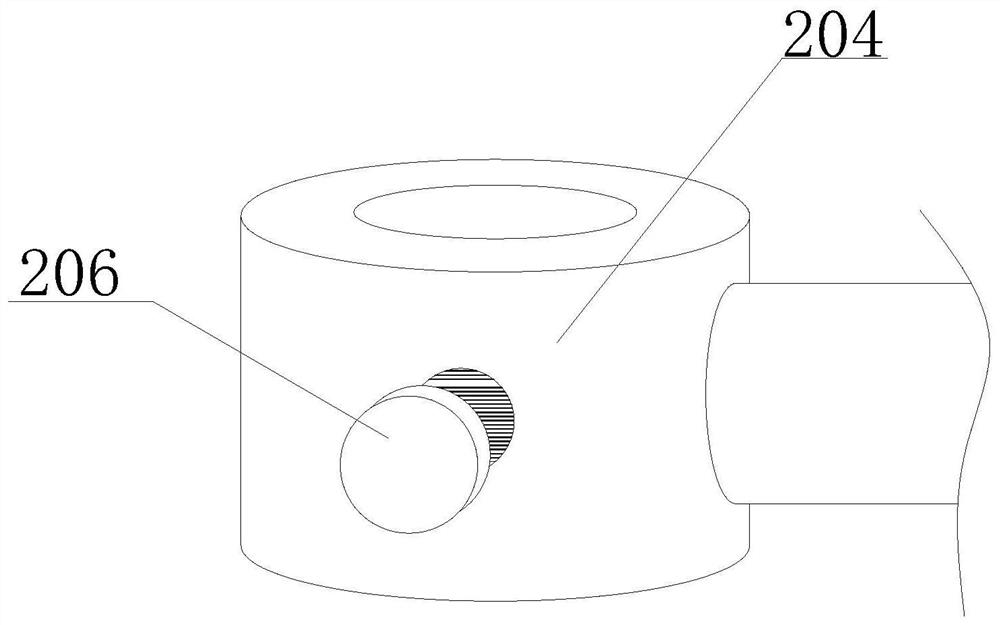

[0039] Working principle: When performing weeding operations in the field, loosen the locking knob 206, turn the adjusting knob 203 to drive the transmission gear 202 to rotate, and at this time the rack 205 is lifted by the action of the transmission gear 202, thereby driving the housing 207 to perform Height adjustment, after adjusting to a suitable height, tighten the locking knob 206, and then push the car body frame 1 to carry out weeding operations. When weeding operations are carried out in the field, the volume of weeds is generally large and difficult to collect, so there is no need to use weeds. Grass collection assembly 4, in the process of using, when bumping into an obstacle, it can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com