Automobile rear axle supporting tool

A technology for automobile rear axles and brackets, which is applied to hand-held tools, manufacturing tools, coil springs, etc., can solve the problem of inconvenient adjustment of the inward extension of the extension arm, and achieve the effect of improving the efficiency of batch assembly and ensuring smooth progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

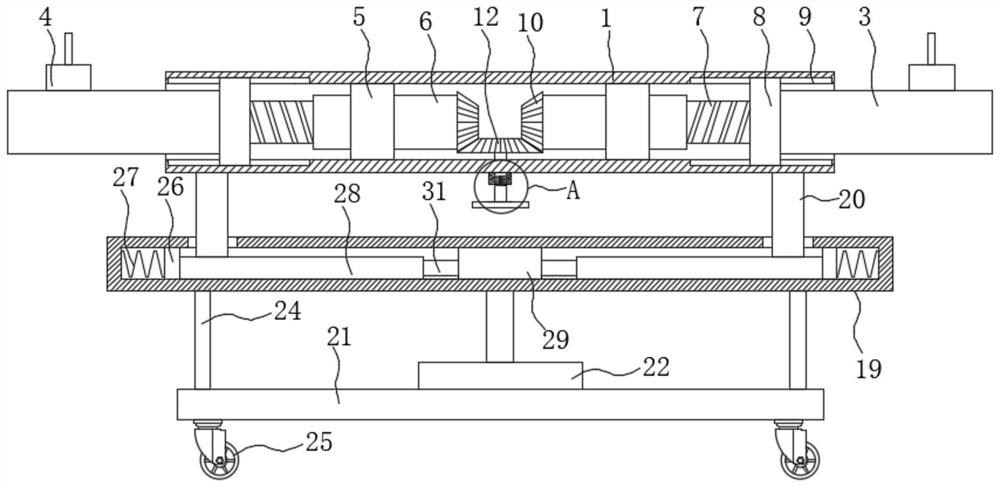

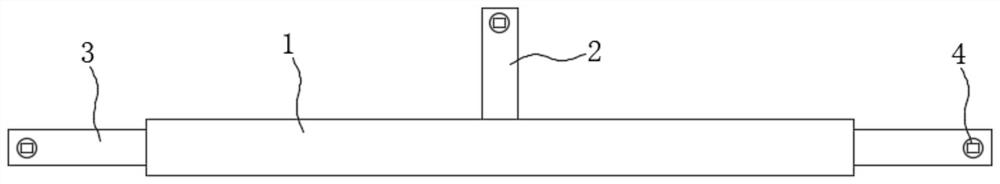

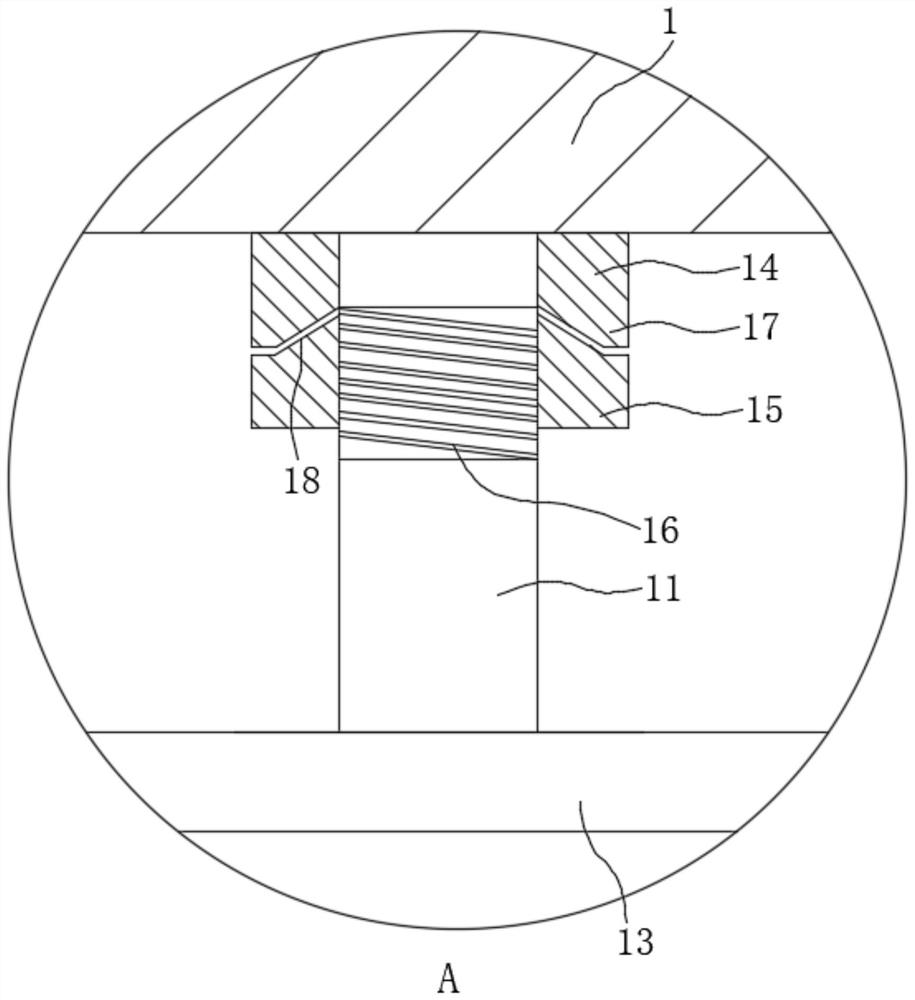

[0033] Please combine Figure 1 to Figure 4 , the car rear axle bracket includes a cross arm 1 and a longitudinal arm 2 vertically arranged with the cross arm 1. The interior of the cross arm 1 is hollow and has openings at both ends. The openings at both ends of the cross arm 1 are interspersed with an extension arm 3. The extension arm 3 can extend or retract in the opening of the cross arm 1. Both the trailing arm 2 and the two extension arms 3 are provided with mounting pieces 4 for connecting to a rear axle (not shown). The mounting part 4 can be selected according to the model of the rear axle. For example, the mounting part 4 can be a circular fixing part (not shown), and the center of the fixing part is provided with a circular groove (not shown), which is used to connect with the crossbeam Mounting and fixing for the rear axle of the grooved cross member. Another example is that the mounting part 4 is a "concave" shape (not shown in the figure), and the bottom of th...

Embodiment 2

[0052] Please combine Figure 5 and Figure 6 , this embodiment 2 is an improved solution of embodiment 1. Each of the universal wheels 25 is connected to the support base 21 through a shock absorber assembly, the shock absorber assembly includes a chute 33 with the notch facing downward, and the inside of the chute 33 is slidably provided with two sliders. 34, the top of the slider 2 34 is connected to the groove wall of the chute 33 through a spring 2 36, and the bottom of the slider 2 34 is connected to the corresponding universal wheel 25 through a fixed rod 35.

[0053] When the bracket is subjected to vibration from the vertical direction, the slider 2 34 will slide in the chute 33 under the action of the vibration force, and compress the spring 2 36 to make it elastically deform to reduce the vibration, further ensuring the assembly process of the rear axle stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com