Casing and magnetic shoe bonding auxiliary device

A technology of auxiliary devices and casings, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of the position of the magnetic steel deviate from the set position, the magnetic steel cannot fit together well, etc. The effect of installation accuracy, less parts, and convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings and specific embodiments.

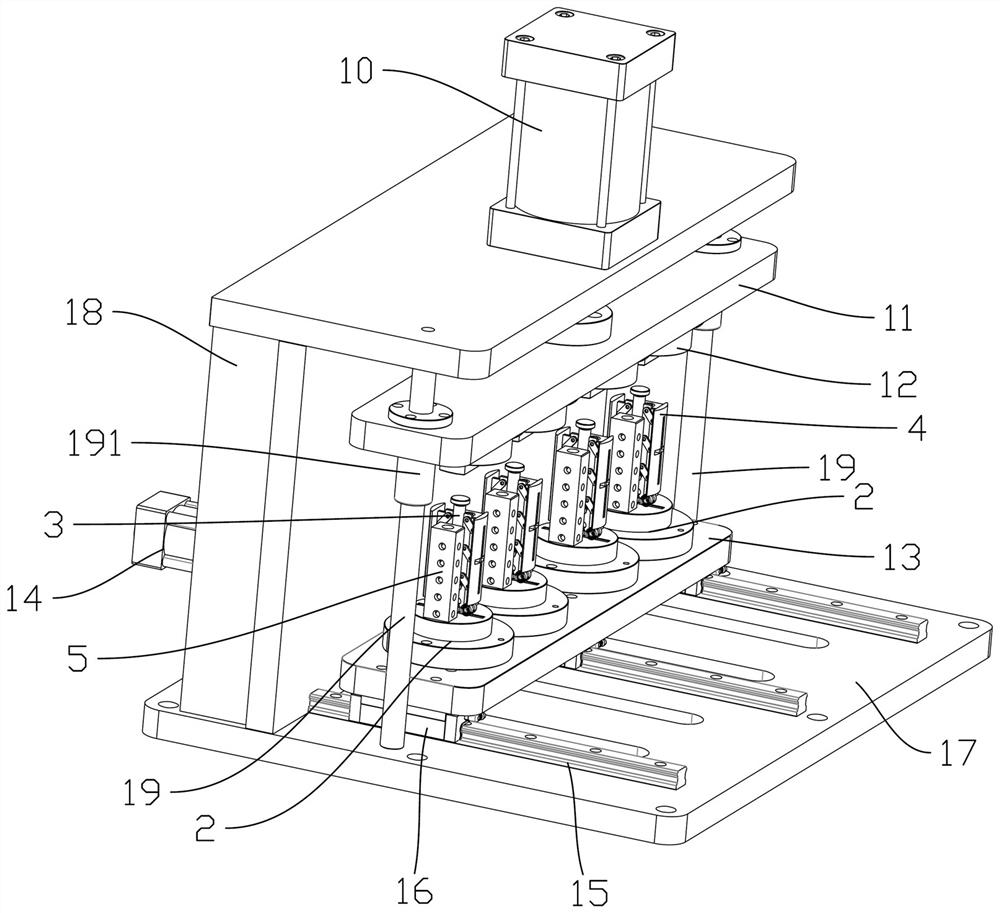

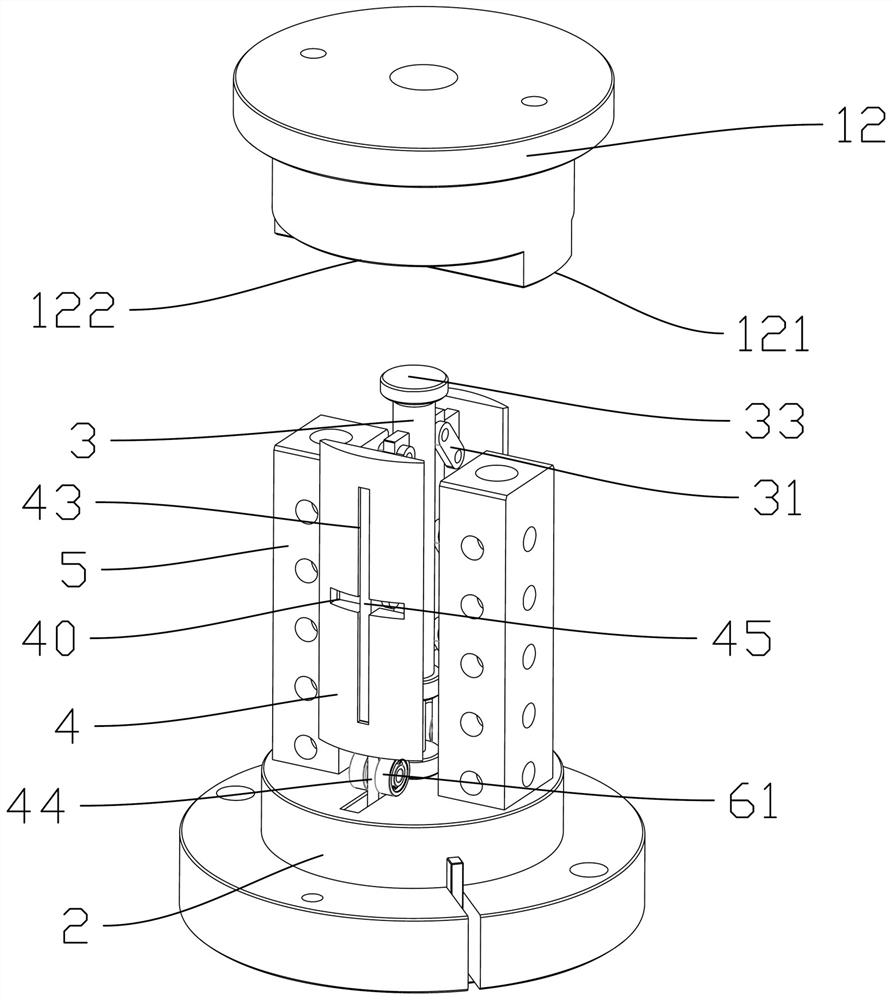

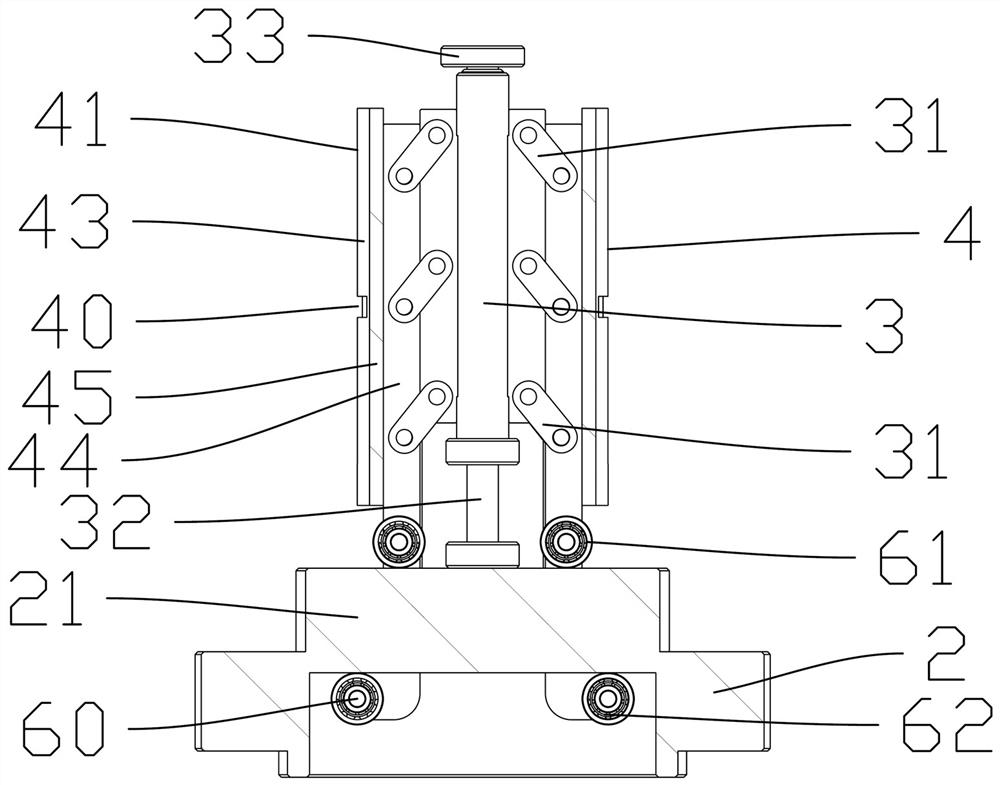

[0025] Depend on Figure 1 to Figure 4 As shown, a casing and magnetic steel bonding auxiliary device of the present invention includes a press 10 and a casing positioning seat 2, the press 10 includes a vertically arranged telescopic rod, and the lower end of the telescopic rod is provided with a horizontally arranged pressing plate 11 , the lower side of the pressing plate 11 is fixed with a number of pressing blocks 12, and each pressing block 12 is provided with a housing positioning seat 2 on the lower side. Translational drive mechanism, the translational drive mechanism is used for moving back and forth of movable plate 13 . Wherein, the press 10 is a cylinder press, and the translation drive mechanism includes a linear cylinder 14, a guide rail 15 and a slider 16. The guide rail 15 is arranged along the front and rear directions, and the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com