Net feeding mechanism and small fruit net sleeve sleeving and boxing machine with same

A technology for packing box machines and net feeding, which is applied in the direction of packaging fruit/vegetables, packaging, packaging machines, etc., which can solve the problems of energy consumption, low efficiency, and low efficiency of netting, so as to reduce damage, reduce energy consumption, and improve The effect of network speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

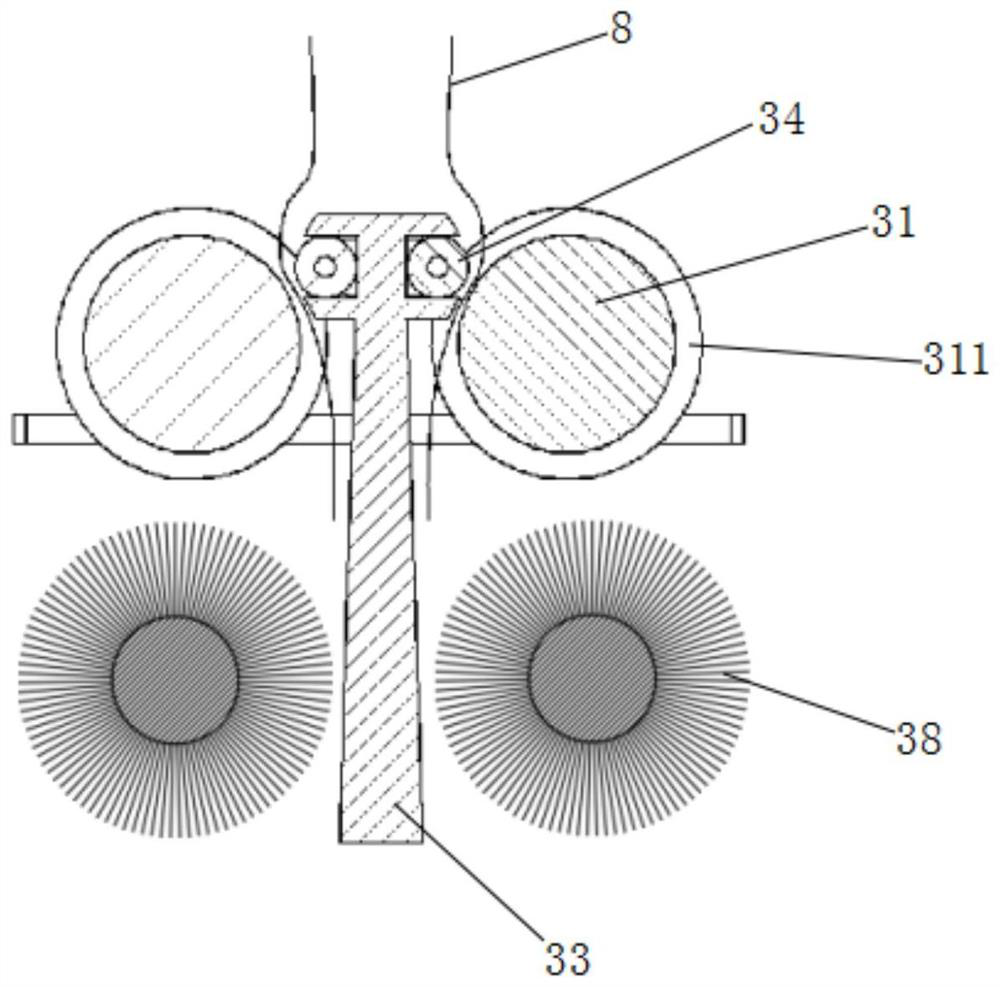

[0063] see Figure 1 to Figure 2 , the present invention provides a web feeding mechanism, which includes two parallel active curved rollers 31, a drive mechanism that drives the two active curved rollers to reverse synchronously, and several movable rollers evenly distributed on the circumference of the top of the stretching column 33. The omnidirectional wheel 34 that rotates; The driving shaft 37 is connected concentrically with the two driving crank rollers 31 respectively, and the respective two ends of the driving shaft 35 and the driven shaft 37 are fixedly supported by the bearing housing 36, and the two gears 32 are respectively connected with the driving shaft 35 and the driven shaft 37 , wherein, the driving shaft 35 drives the two gears 32 through the externally connected stepping motor 12 to realize the synchronous reverse movement of the two driving curved rollers 31, and matches the net feeding speed of the net feeding mechanism 3 with the net speed, greatly Th...

Embodiment 2

[0065] see Figure 3 to Figure 4 , the present invention provides a net delivery mechanism, the main structure of which is the same as that of Embodiment 1 of the net delivery mechanism, including figure 1 Shown: two driving crank rollers 31 parallel to each other, a drive mechanism that drives the two driving crank rollers to reverse synchronously and several rotatable omnidirectional wheels 34 evenly distributed on the circumference of the top of the stretching column 33; To wheel 34 is positioned between two driving curved rollers 31, and driving mechanism is made up of two gears 32, driving shaft 35, bearing seat 36 and driven shaft 37 that mesh with each other, and driving shaft 35 and driven shaft 37 are connected with two driving shafts respectively. The curved rollers 31 are connected concentrically, and the respective two ends of the driving shaft 35 and the driven shaft 37 are fixedly supported by the bearing housing 36, and the two gears 32 are respectively connecte...

Embodiment 3

[0068] see Figure 5 to Figure 6 , the present invention provides a kind of net feeding mechanism, and its main body structure is similar to the embodiment 2 of net feeding mechanism, comprises two mutually parallel active curved rollers 31, the drive mechanism that drives two active curved rollers to reverse synchronously and evenly distributed Several rotatable omnidirectional wheels 34 arranged on the circumference of the top of the strut column 33; 36 and the driven shaft 37, the driving shaft 35 and the driven shaft 37 are connected concentrically with the two driving crank rollers 31 respectively, and the respective two ends of the driving shaft 35 and the driven shaft 37 are fixedly supported by the bearing housing 36, and the two The gears 32 are respectively connected with the driving shaft 35 and the driven shaft 37, wherein the driving shaft 35 drives the two gears 32 through the externally connected stepping motor 12 to realize the synchronous reverse movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com