A bearing machining and cutting device

A bearing processing, No. 1 technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of manually changing the processed parts, easy scattering of waste dust into the air, and endangering the health of workshop staff, etc., to achieve The effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is attached figure 1 , to further illustrate the specific implementation of a bearing machining and cutting device of the present invention. A bearing machining and cutting device of the present invention is not limited to the description of the following embodiments.

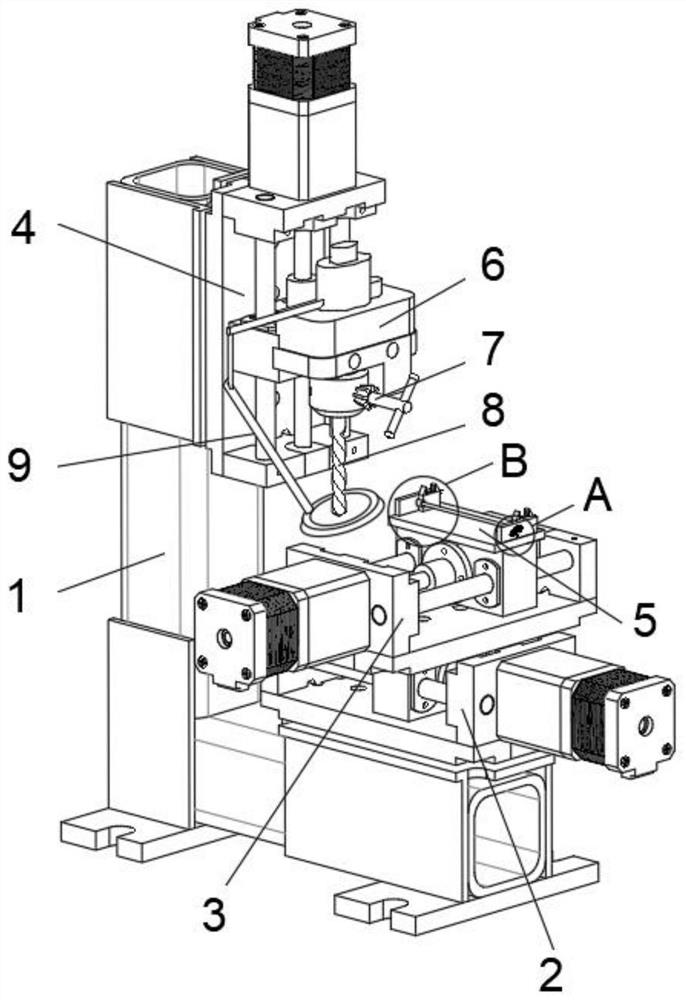

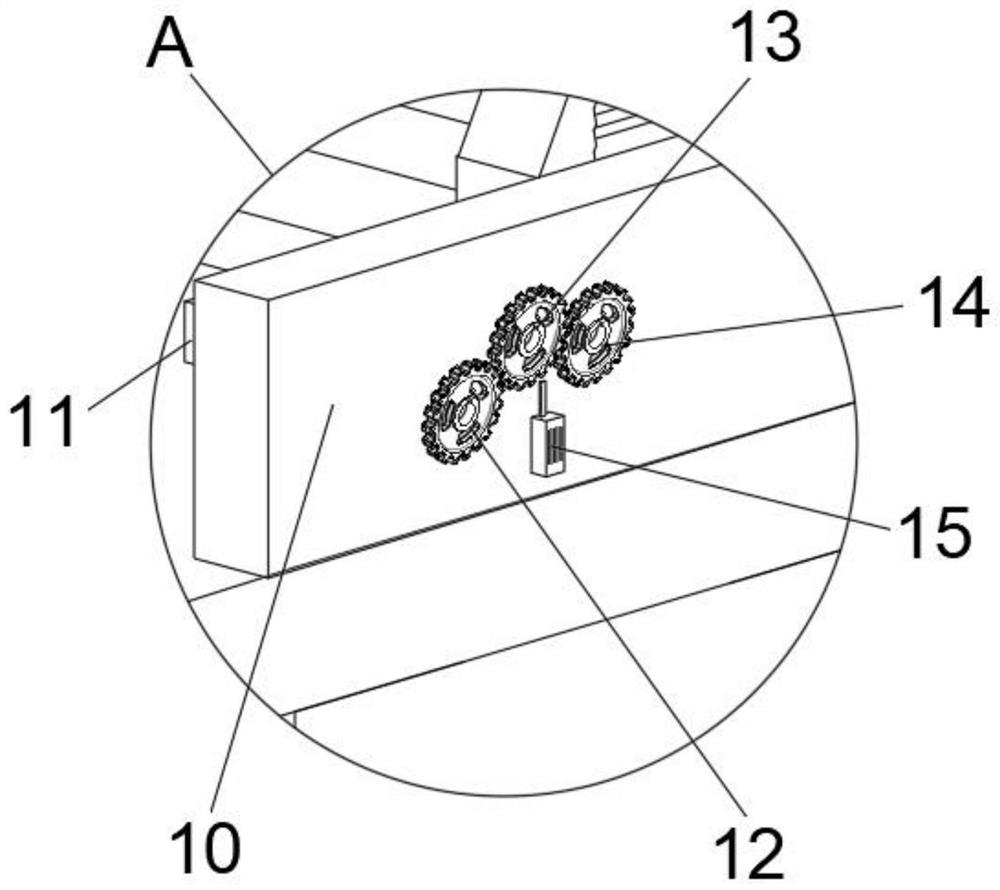

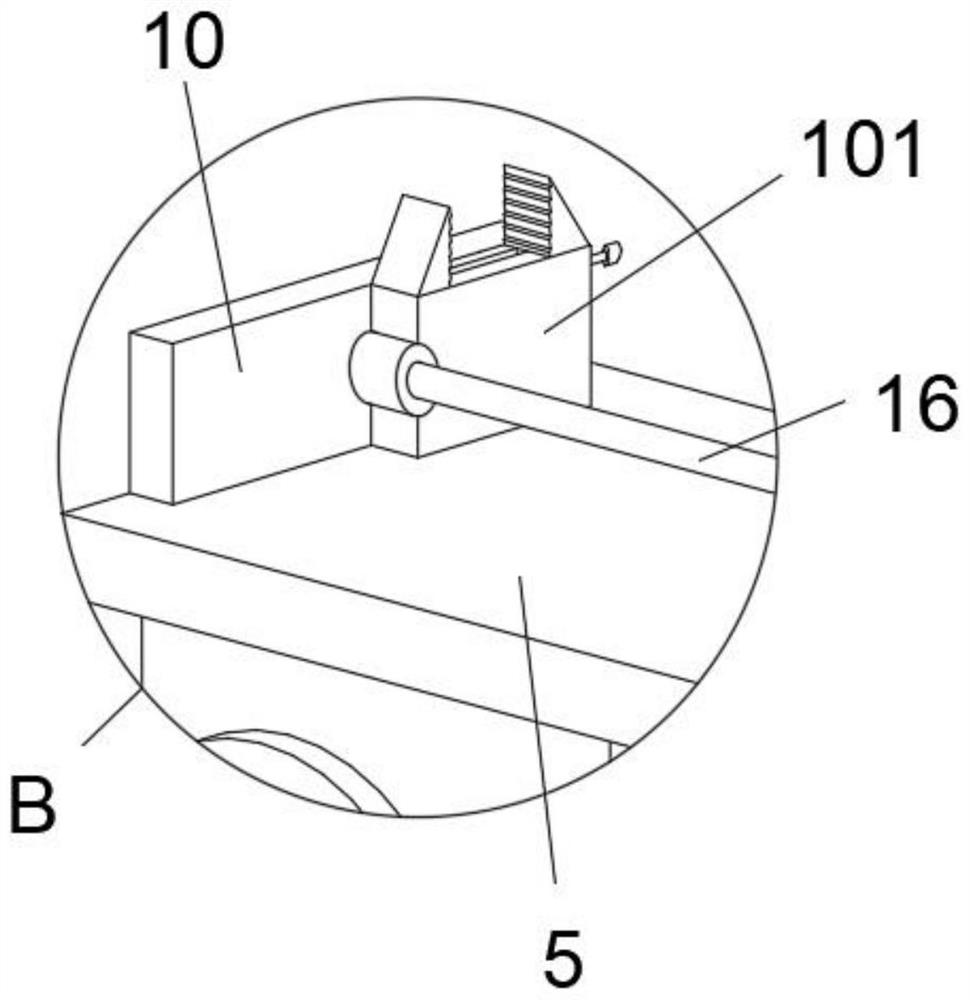

[0028] This embodiment provides a specific structure of a bearing processing and cutting device, such as Figure 1-5 As shown, a bearing machining and cutting device includes:

[0029] Frame 1 is provided with a transmission assembly on its surface. The transmission assembly includes No. 1 transmission mechanism 2, No. 2 transmission mechanism 3 and No. The transmission mechanisms of the group are respectively located on the X, Y and Z axes, and the No. 1 transmission mechanism 2 can drive the No. 2 transmission mechanism 3 to perform linear motion, and the No. 3 transmission mechanism 4 alone performs linear motion on the Z axis;

[0030] The surface of the supporting movable part on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com