Novel direct opening type injection molding machine synchronous hooping device

An injection molding machine, direct-opening technology, applied in the field of the new direct-opening injection molding machine synchronous embracing device, can solve the problems of mold pull rod damage, unsmooth mold clamping and mold opening, noise, etc., and achieves small stroke, short cycle, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

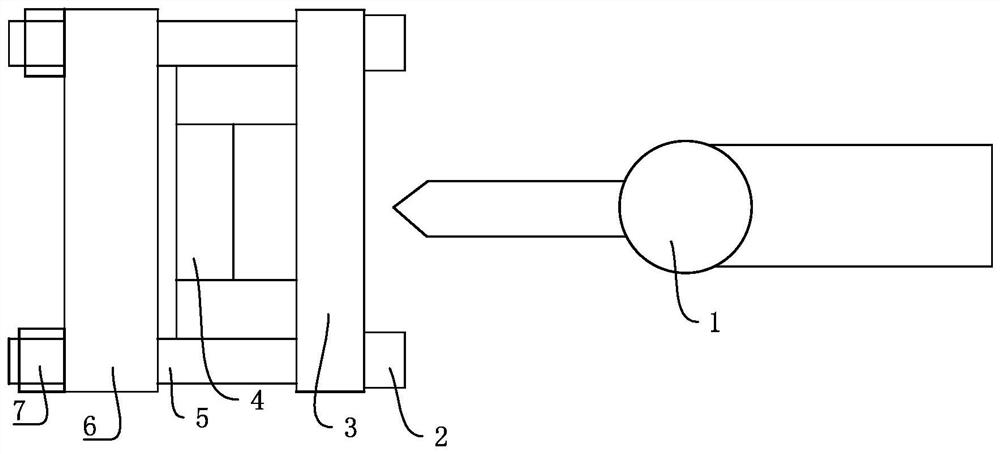

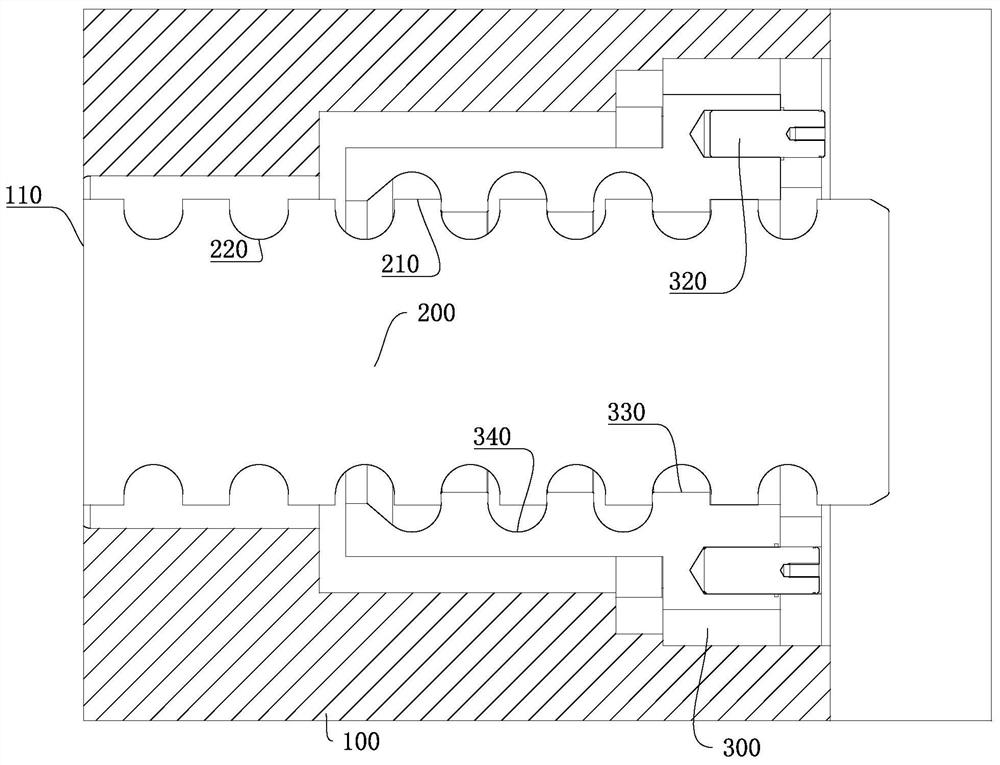

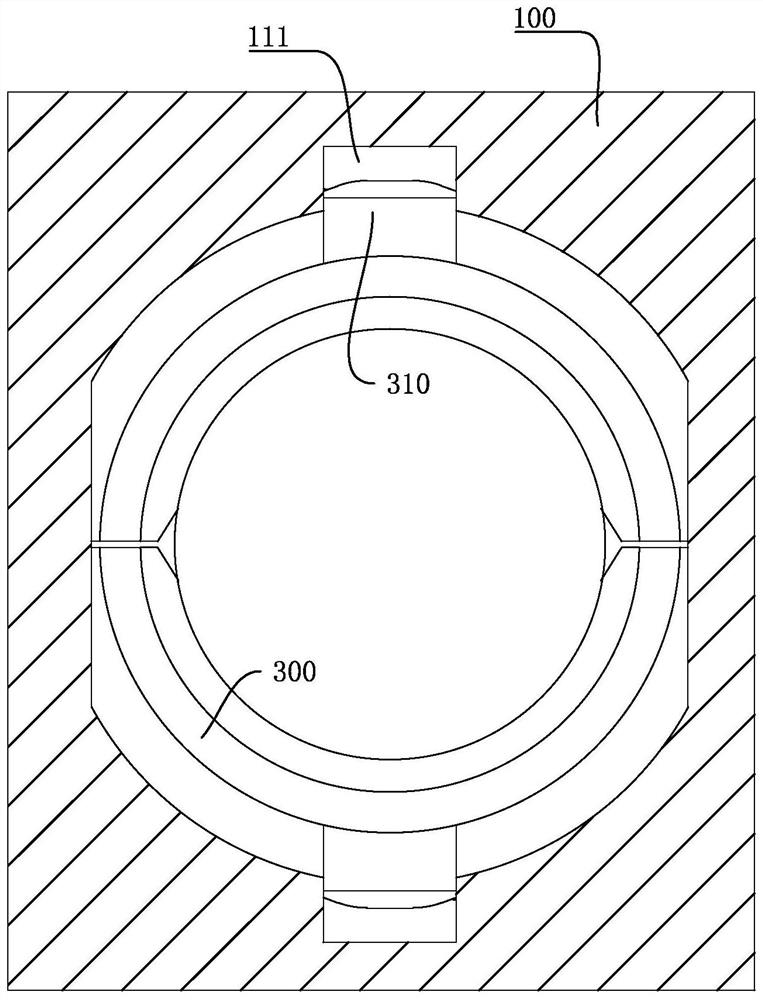

[0029] Such as Figure 2-4 As shown, a new type of direct open injection molding machine synchronous clutching device, including:

[0030] The movable template 100 drives the mold to move towards the fixed mold during the mold closing process, and moves away from the fixed mold during the mold opening process.

[0031] The pull rod 200 passes through the movable template 100 and is used to guide the movable template 100, and guides the movement of the movable template 100 through the pull rod 200, thereby realizing the process of mold closing and mold opening.

[0032] Engagement device, the engagement device is installed in the moving template 100, the engagement device includes two half-engagement nuts 300, when the injection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com