Driving shaft slip deflection angle checking method and driving shaft slip deflection angle checking system

A driving shaft and calibration technology, which is applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as slippage distance, three-ball pin detachment, poor accuracy of simulation results, and influence on vehicle driving. To achieve the effect of accurate curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary, and are only for explaining the present application, and should not be construed as limiting the present application.

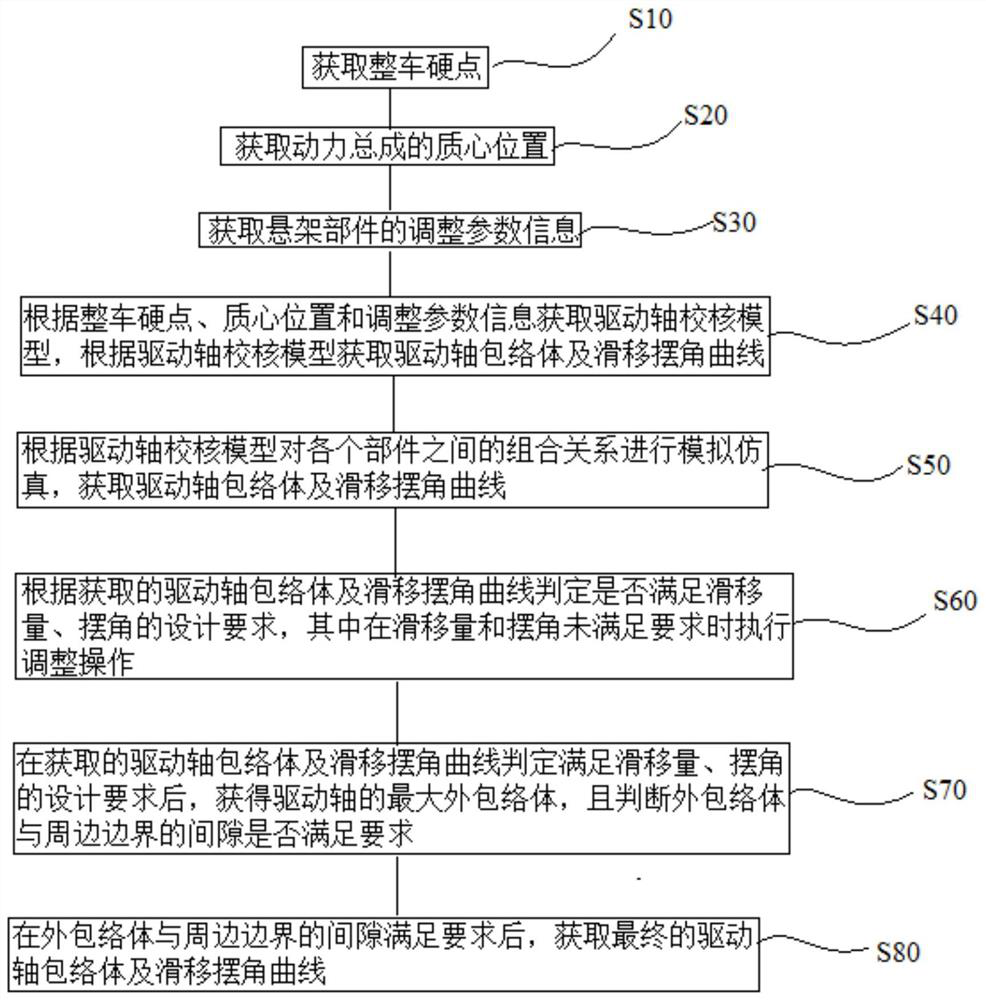

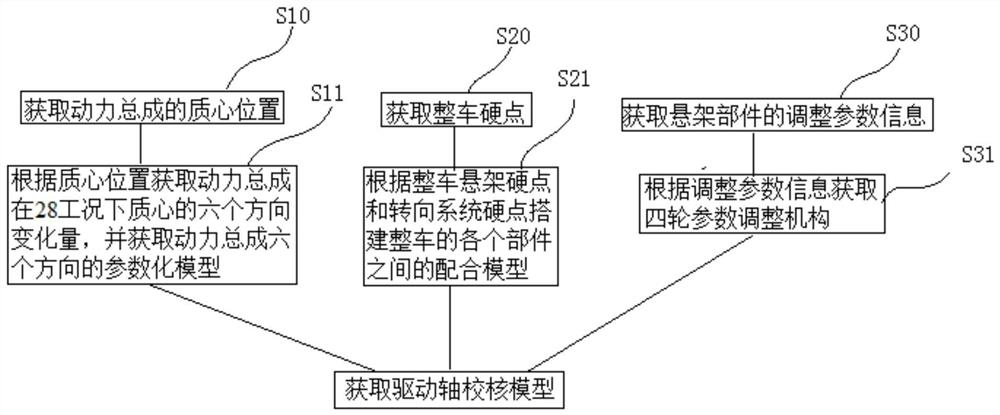

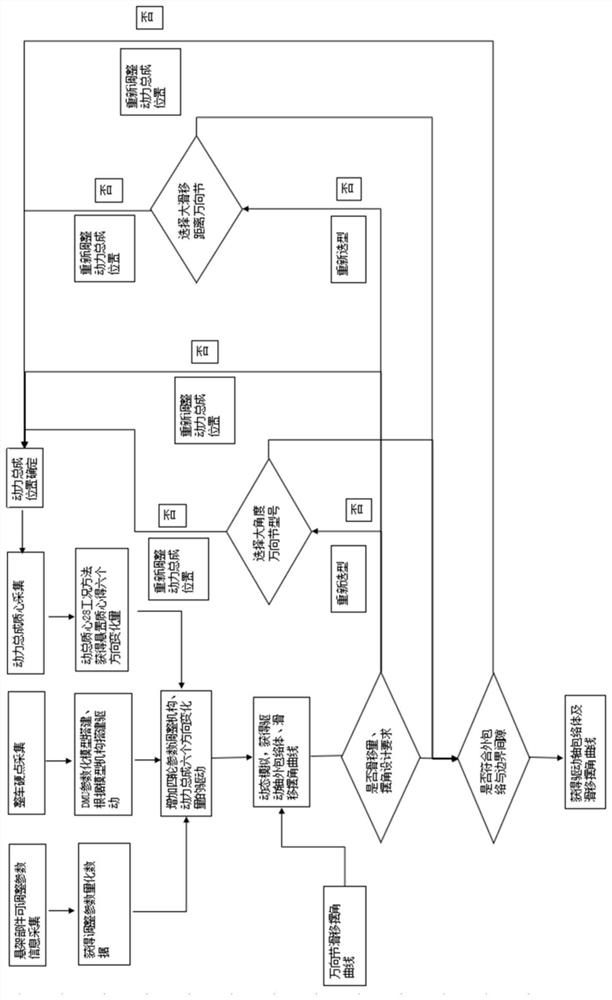

[0025] In the prior art, the check of the slip angle of the drive shaft is only based on the check results, evaluated according to the empirical value and comprehensively determined by the actual vehicle road test verification, and there is a problem of insufficient design check or excessive design. Moreover, it is impossible to simulate the change of the total dynamic displacement of each working condition or a specific working condition on the basis of the existing drive, and the influence of the four-wheel parameters on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com