High-temperature and high-pressure unsteady-state equilibrium condensate oil gas-phase permeation test method

A steady-state balance, high temperature and high pressure technology, applied in the direction of measuring devices, analytical materials, permeability/surface area analysis, etc., can solve the problems of heavy experimental workload, complicated methods, and low precision, and achieve improved experimental data accuracy and simple operation Effects that are easy to implement and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

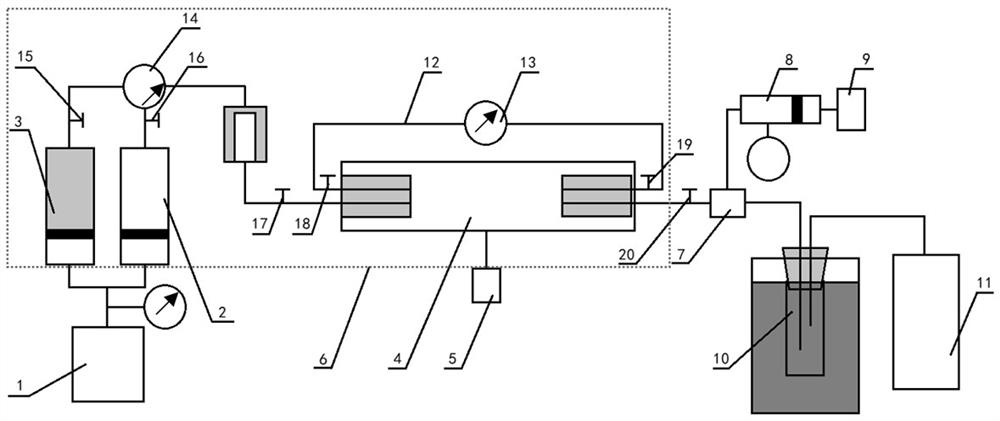

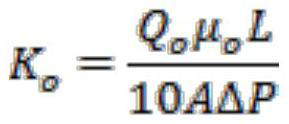

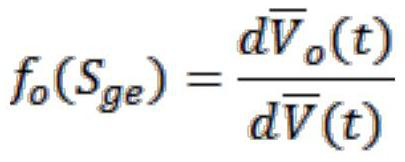

Method used

Image

Examples

Embodiment

[0057] A high-temperature and high-pressure non-steady-state equilibrium condensate gas phase permeability test method includes the following steps in sequence:

[0058] S1. After extracting, cleaning and drying the core retrieved from the site, measure the length L=10.5cm, diameter d=6.9cm, core porosity φ=13.47%, and calculate the cross-sectional area of the core A=37cm 2 and pore volume Vp = 54cm 3 ;

[0059] S2. According to the national standard condensate gas sample preparation, the maximum condensate oil saturation S is measured om is 29%, the dew point is 46MPa, and the pressure P corresponding to this degree of saturation is obtained Som is 25MPa, through the phase state simulation of condensate gas samples, the equilibrium oil phase composition at 25MPa is predicted, and this composition is used to predict the separation experiment, and the equilibrium oil simulation volume coefficient B is obtained op is 1.65;

[0060] S3. Preparation of balanced oil and gas s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com