Pull-down opening and closing structure of computerized flat knitting machine

A computerized flat knitting machine and opening and closing device technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of complex rake roller structure, complex technical operation, high manufacturing cost, etc., achieve low cost and improve stability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

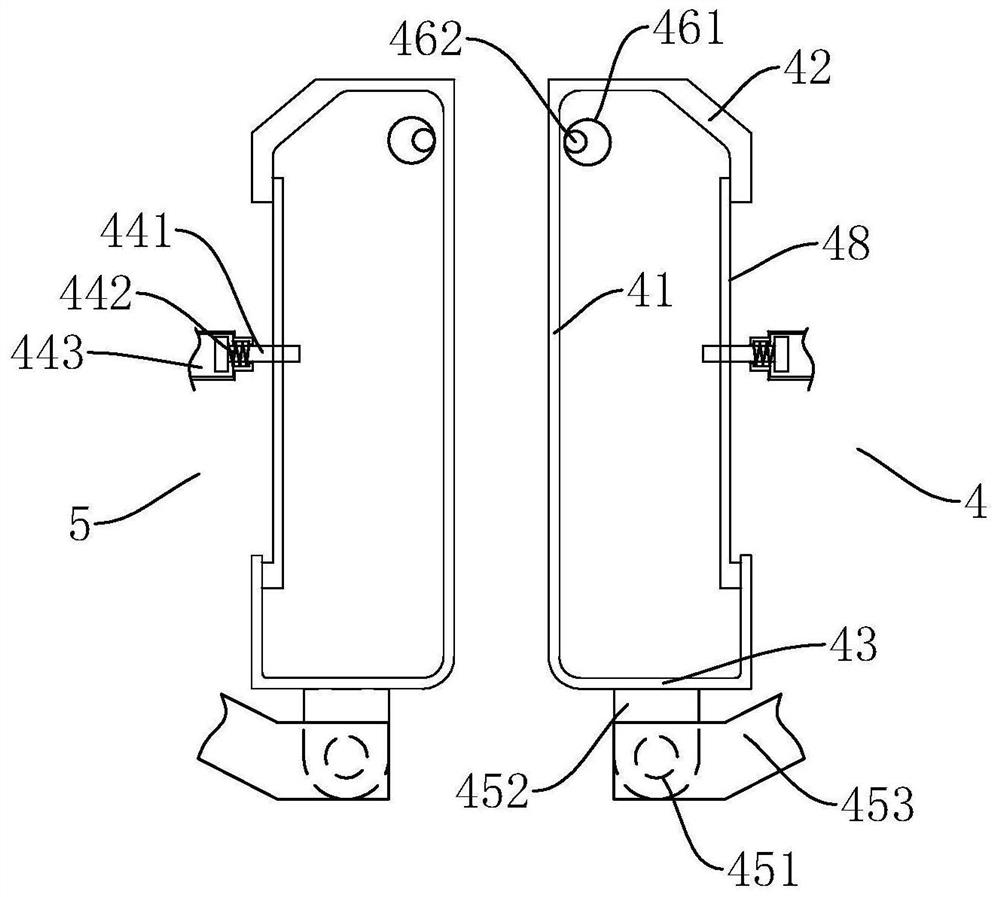

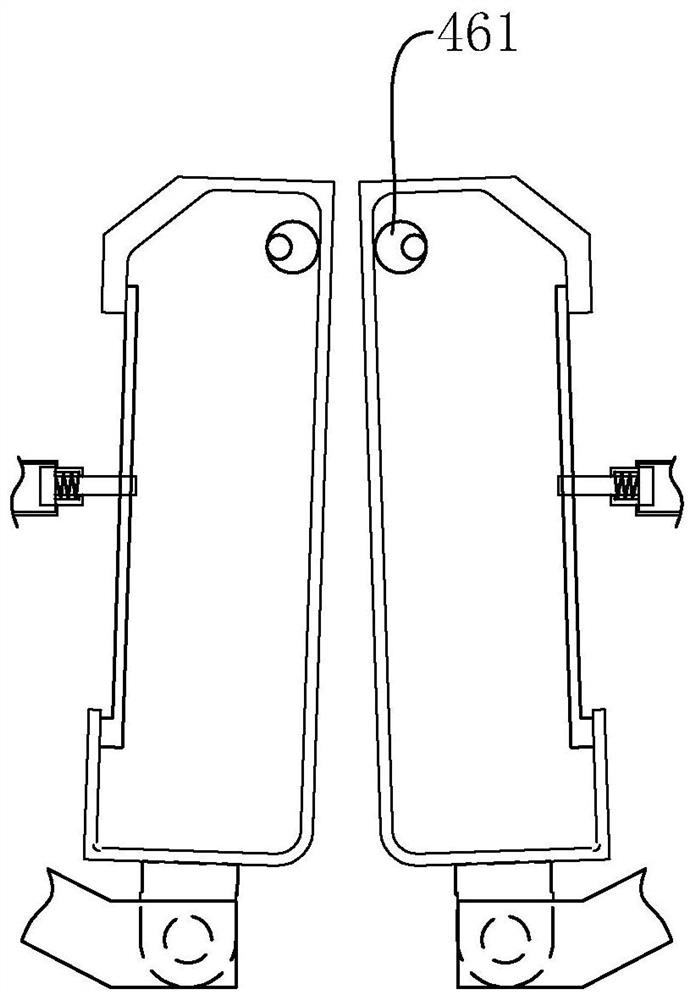

[0042] combine Figure 1 to Figure 11 The pull-down opening and closing structure of the computerized flat knitting machine of the present invention will be further described.

[0043] A pull-down opening and closing structure of a computerized flat knitting machine is characterized in that it includes an opening and closing device and a rake-type pull-down device.

[0044] The opening and closing device comprises a front panel frame 5 and a rear panel frame 4 hinged in a left-right symmetrical state in the computerized flat knitting machine, a pulling channel 3 is formed between the front panel frame 5 and the rear panel frame 4, and a Both the frame 5 and the rear frame 4 have a plurality of windows 113 corresponding to each other, and the front frame 5 and the rear frame 4 are connected with a swing that drives the front frame 5 and the rear frame 4 to swing towards each other or back to the other side. drive assembly 46 .

[0045] The rake pull-down device includes a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com