Installation Process of Impeller Hub Cap of Nuclear Main Pump

An installation process and hub cap technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of the nuclear main pump not being manufactured, generating vibration, and having no experience to learn from, achieving good practical effects and preventing vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

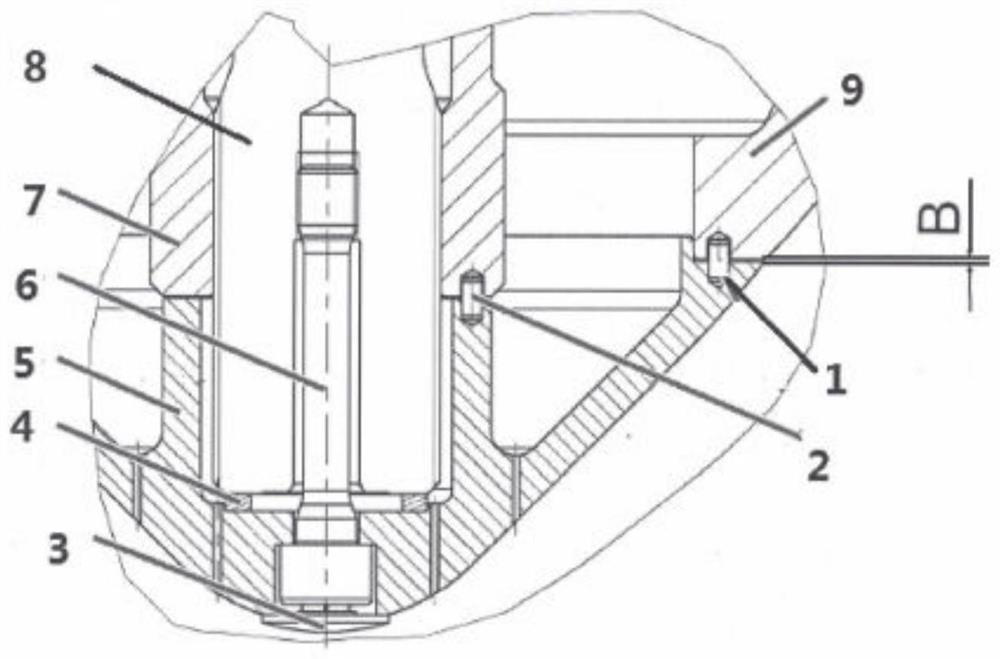

[0036] Such as figure 1 As shown, a nuclear main pump impeller hub cap installation process adopts the method of drilling the pin holes of the impeller 9: use the first cylindrical pin 1 with the tip to determine the pin hole position of the impeller 9 by trying to install the impeller hub cap 5, The first cylindrical pin 1 and the second cylindrical pin 2 in the circumferential direction are positioned at the same time to complete the radial positioning of the impeller hub cap 5, and the gap between the impeller hub cap 5 and the impeller 9 is completed by grinding and adjusting the thickness of the gasket 4 to achieve The axial location of impeller hub cap 5, said method comprises the following steps:

[0037] 1) Install the first cylindrical pin 1 and the second cylindrical pin 2 with the tip respectively in the impeller hub cap;

[0038] 2) Hold up the impeller hub cap 5 and ensure that the second cylindrical pin 2 can smoothly enter the pin hole of the impeller nut 7;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com