Agricultural rapid corn thresher

A technology of thresher and threshing mechanism, applied in agricultural machinery and implements, agriculture, threshing equipment, etc., can solve the problems of inability to continue operation, cumbersome operation process, prone to failure, etc., to save labor costs, ensure quality, and facilitate collection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

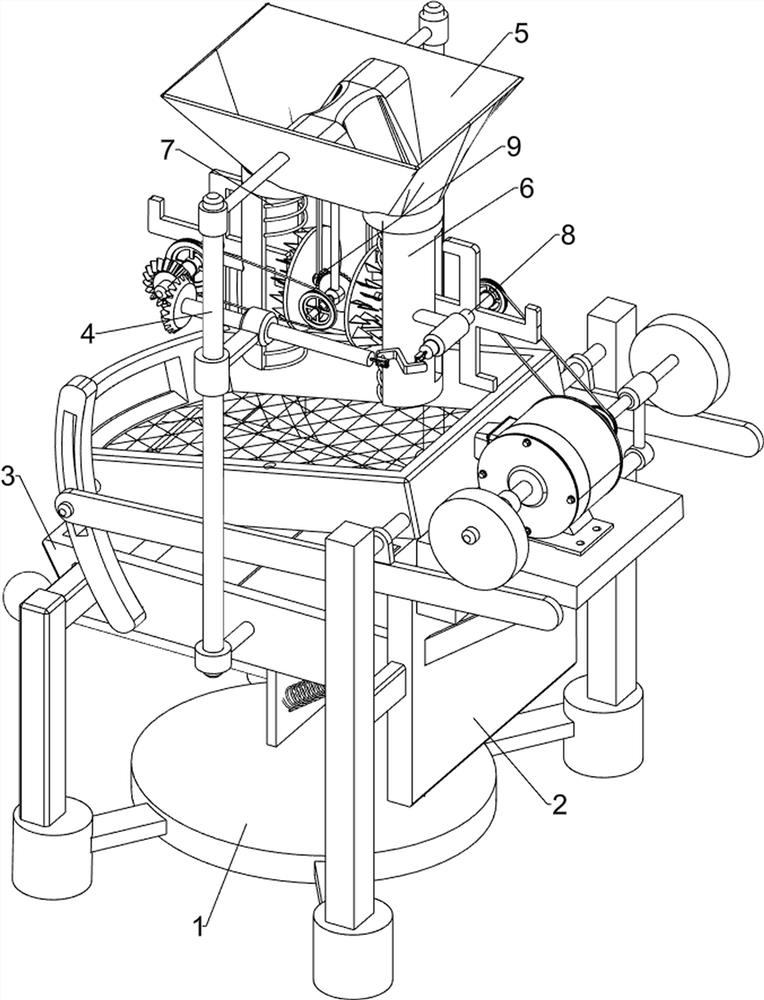

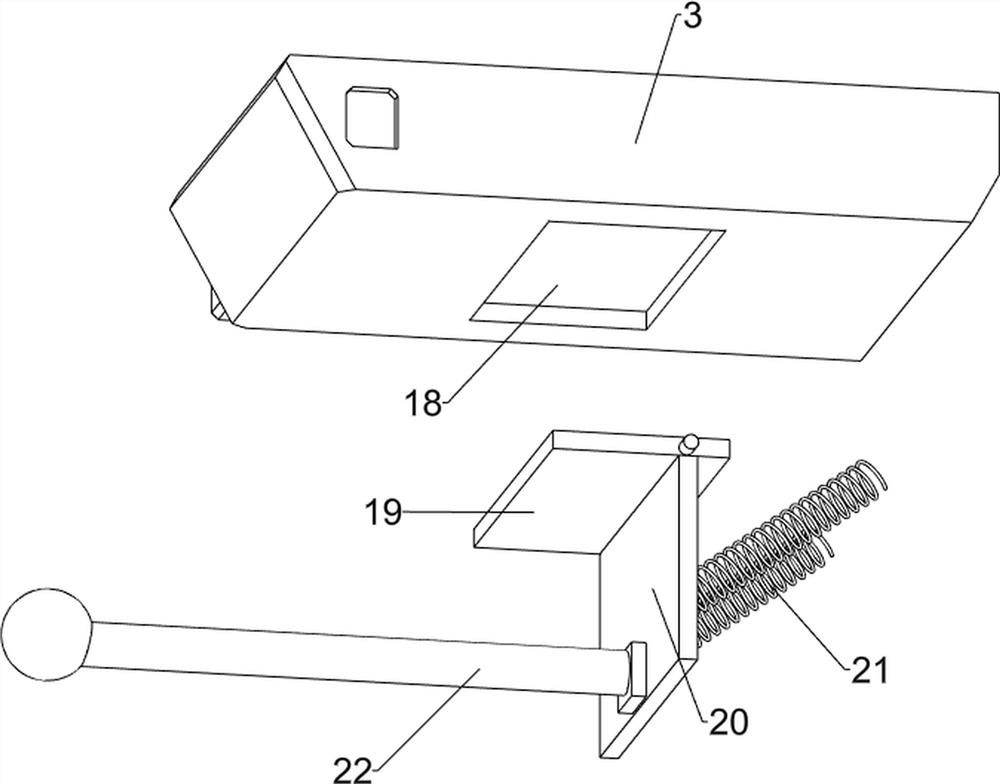

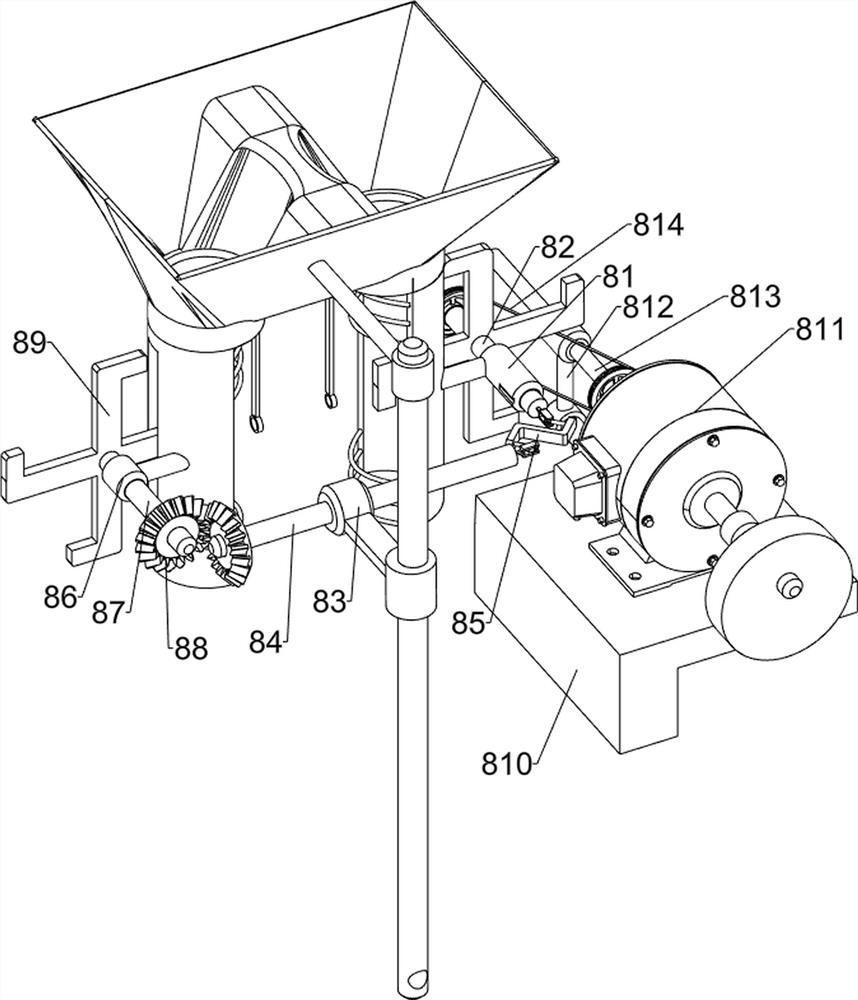

[0023] like figure 1 , figure 2 and image 3 Shown, an agricultural corn fast thresher, comprising a mounting bracket, the fixed plate 2, the collecting tank 3, a support column 4, the bidirectional hopper 5, drop tube 6, the arcuate frame 7, the pressing mechanism 8 and degranulation mechanism 9, the right frame 1 is provided with a fixing plate 2, is provided between the mounting bracket 2 and the fixing plate 1 has left the collection tank 3, symmetrically provided on both sides with a collection tank 4, 4 upper front and rear two support columns supporting column 3 is provided between the hopper 5 with a two-way, two-way two lower bottom of the hopper 5 at the discharge port 6 is provided with a similar side of the blanking tube 6, two tubes are opened blanking square grooves, two opposite drop tube 6 slotted side are opened, two rectangular grooves vertical drop tube 6 is provided with a curved carrier 7, threshing means 6 is provided with a pressing mechanism 8, the middle bo...

Embodiment 2

[0028] like Figure 4 and Figure 5 Shown, an agricultural corn sheller fast, on the basis of the embodiment 1 further comprises a rotary shaft 10, the filter box 11, the arcuate groove plate 12, the sliding shaft 13, the swing lever 14, the seventh bearing seat 15 seventh shaft 16 and cam 17, the right frame 1 is provided with a rotary shaft 10 is rotated, the rotary shaft 10 is positioned above the fixed plate 2, the rotation shaft 10 is located above the central collection tank is provided with a filter housing 11, filter block 113, 3 left sides symmetrically collection box 12 is provided with an arcuate groove plate, interior plate 12 are two arcuate grooves opening arcuate groove, the left sides of the filter box 11 is provided with a slide shaft 13, the spool shaft 13 and the arcuate groove mating arcuate slot plate 12, both ends of the rotation shaft 10 is provided with a rocking lever 14, the swing lever 14, respectively two sliding shaft 13 close to one end of the two rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com