Small horizontal combined hard shielding device

A shielding device and horizontal technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increased dangerous sources of live work, short-circuiting of human body between phases, cumbersome problems, etc., and achieve convenient and safe insulation and shielding operation of live work, and shielding installation The effect of shortening and dismantling time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

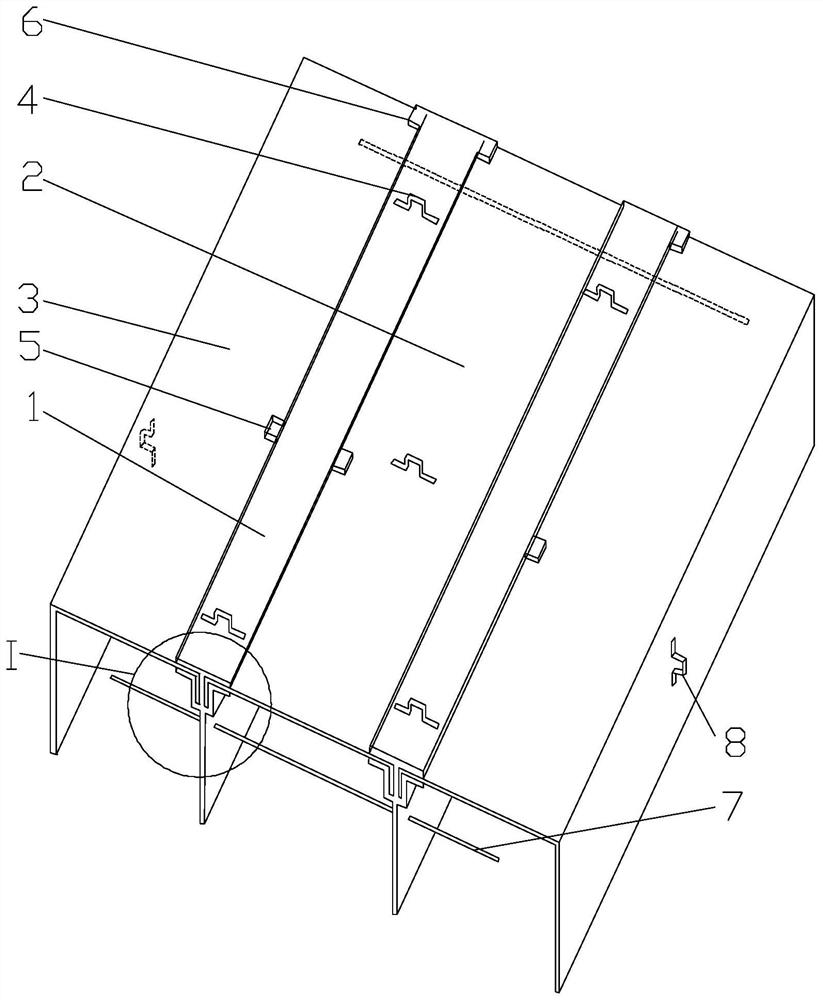

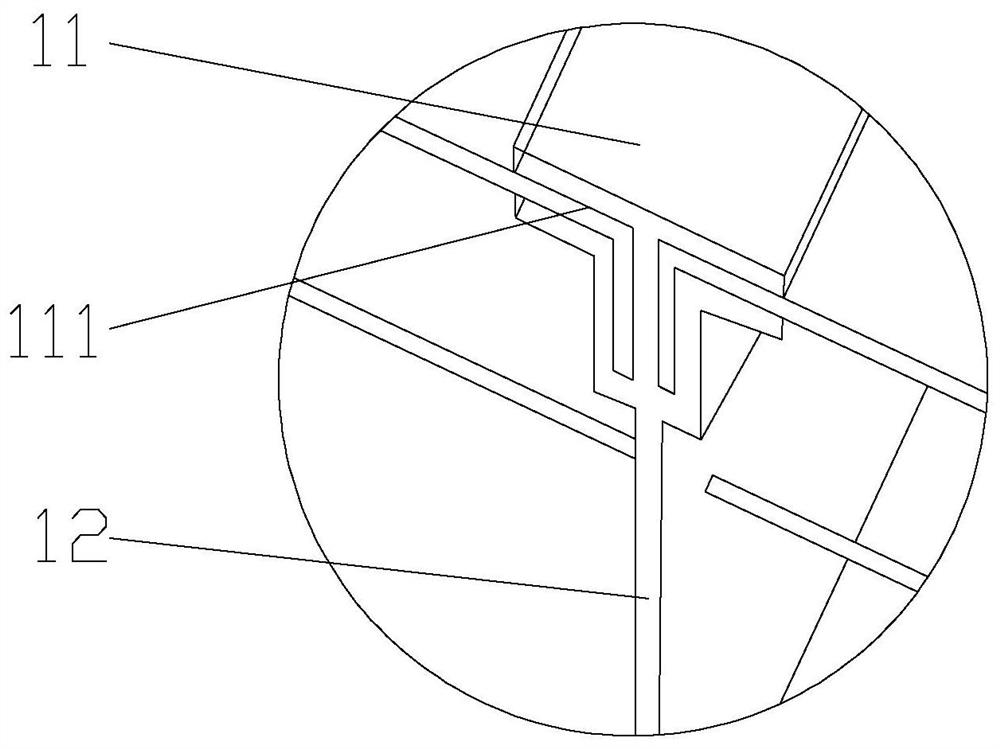

[0015] A small horizontal combined rigid shielding device such as figure 1 , 2 As shown, it includes a main beam 1, a mobile slide plate 1, a mobile slide plate 2 3, a lifting assembly, a moving limit block 5, a fixed limit block 6, a support rod 7, and a push-pull handle 8. The lifting assembly includes a plurality of lifting handles 4, The main beam 1 includes a beam main body 11 and a connecting plate 12 , the connecting plate 12 is arranged vertically and integrally connected with the lower surface of the beam main body 11 .

[0016] There are two main beams 1, and the two main beams 1 are arranged parallel to each other at intervals. The upper surface of each beam main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com