Reusable mask and mask box matched with same for use

A mask and box body technology, applied in the field of mask boxes, can solve the problems of not considering antibacterial properties, not taking more consideration of drying and disinfection of masks, increasing production and processing procedures, etc., to achieve excellent antibacterial and filtration properties, and the production process is simple and fast. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

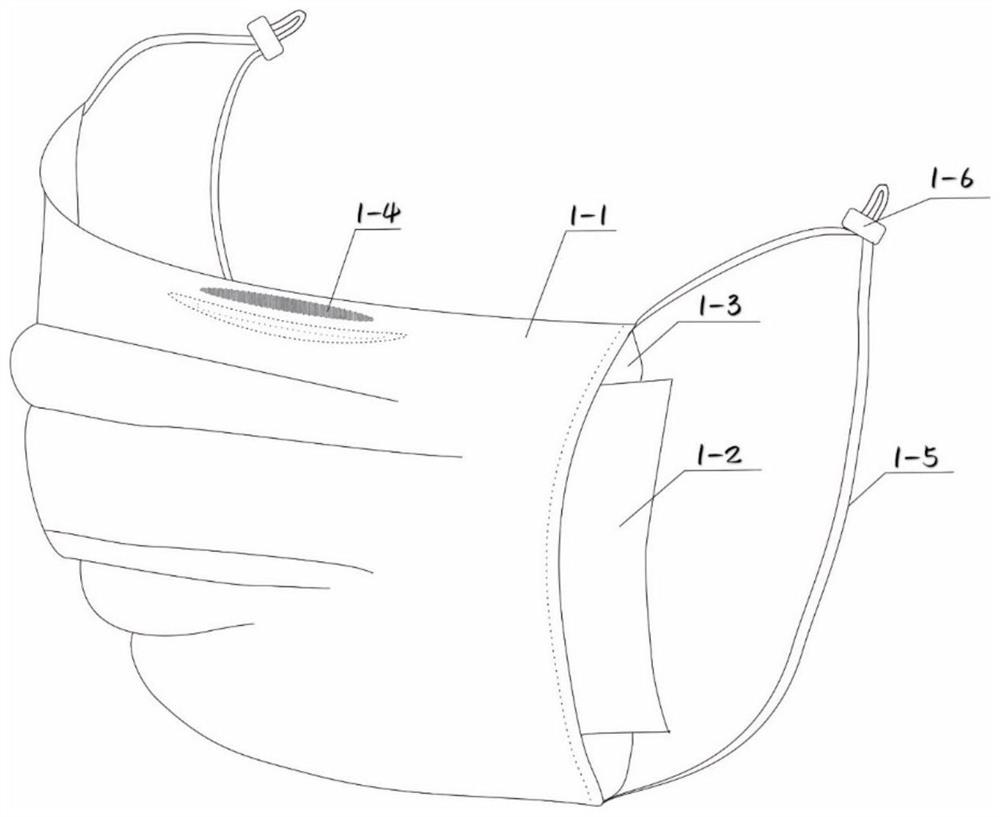

[0031] figure 1 As shown, a reusable mask includes a cover body, a filter core layer 1-2, ear straps 1-5 and buckles. The cover body includes an antibacterial outer layer 1-1, a skin-friendly inner layer 1-3 and a nose bridge strip 1-4; buckles are arranged on the ear straps 1-5, and the ear straps 1-5 are fixed at both ends of the cover body. The nose bridge strip 1-4 is fixed on the middle and upper part of the sleeve body, and an opening is provided on one side of the sleeve body for putting in or taking out the filter core layer 1-2. The antibacterial outer layer 1-1, the skin-friendly inner layer 1-3 and the ear straps 1-5 are formed into a cover body of the mask through ultrasonic hot pressing, and the nose bridge strip 1-4 is directly built into the cover body during ultrasonic hot pressing reinforcement The upper center is compacted.

[0032] The antibacterial fiber constituting the antibacterial outer layer 1-1 is regenerated polyester (R-PET), and the antibacterial...

Embodiment 2

[0040] In this embodiment, except for the following distinguishing technical features, other technical features are the same as in Embodiment 1:

[0041] The antibacterial outer layer 1-1 adopts non-woven fabric instead of fabric, and the polymer material constituting the antibacterial fiber adopts polyester instead of regenerated polyester (R-PET).

[0042] The fiber section in the antibacterial outer layer 1-1 is replaced by a non-circular shape, and the weight of the antibacterial outer layer 1-1 is 100g / m 2 .

[0043] Antibacterial outer layer 1-1 The method of introducing components with antibacterial properties is to replace the dipping method by digital printing, and the position of introducing components with antibacterial properties is replaced by the fiber surface instead of the inside of the fiber, accounting for 100% of the outer layer, containing The antimicrobial component accounts for 100% of the overall fiber.

[0044] Components with antibacterial properties...

Embodiment 3

[0051] In this embodiment, except for the following distinguishing technical features, other technical features are the same as in Embodiment 1:

[0052] The antibacterial outer layer 1-1 adopts grid structure instead of fabric, and the polymer material constituting the antibacterial fiber adopts polyamide instead of regenerated polyester (R-PET).

[0053] The antibacterial outer layer 1-1 introduces the antibacterial component by coating instead of the dipping method, and the position of introducing the antibacterial component is replaced by the fabric surface instead of the fiber.

[0054] Components with antibacterial properties use natural plant extracts to replace metal ions such as silver, copper, zinc, and magnesium.

[0055] The skin-friendly inner layer 1-3 uses a grid structure composed of fibers instead of fabrics, and the functional powder added to the fibers uses micron or nanometer jade powder instead of micron or nanometer mica flakes.

[0056] The macromolecul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap