Elastic deformation adjusting method for middle frame plate in FCT tester

An adjustment method and elastic deformation technology, applied in the field of FCT testing machines, can solve problems such as subsidence of floating micro-needle block modules, contact problems, and insufficient probe travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

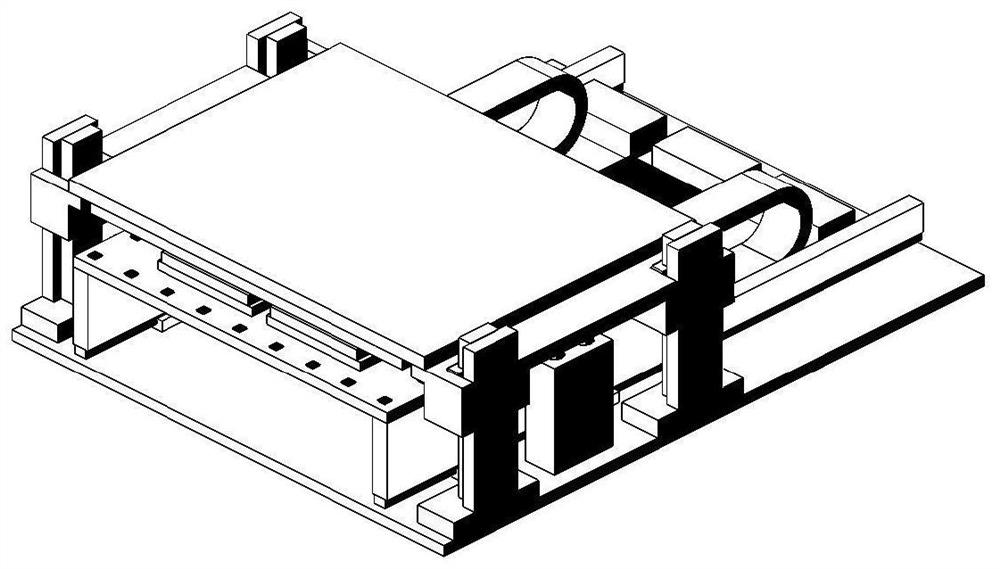

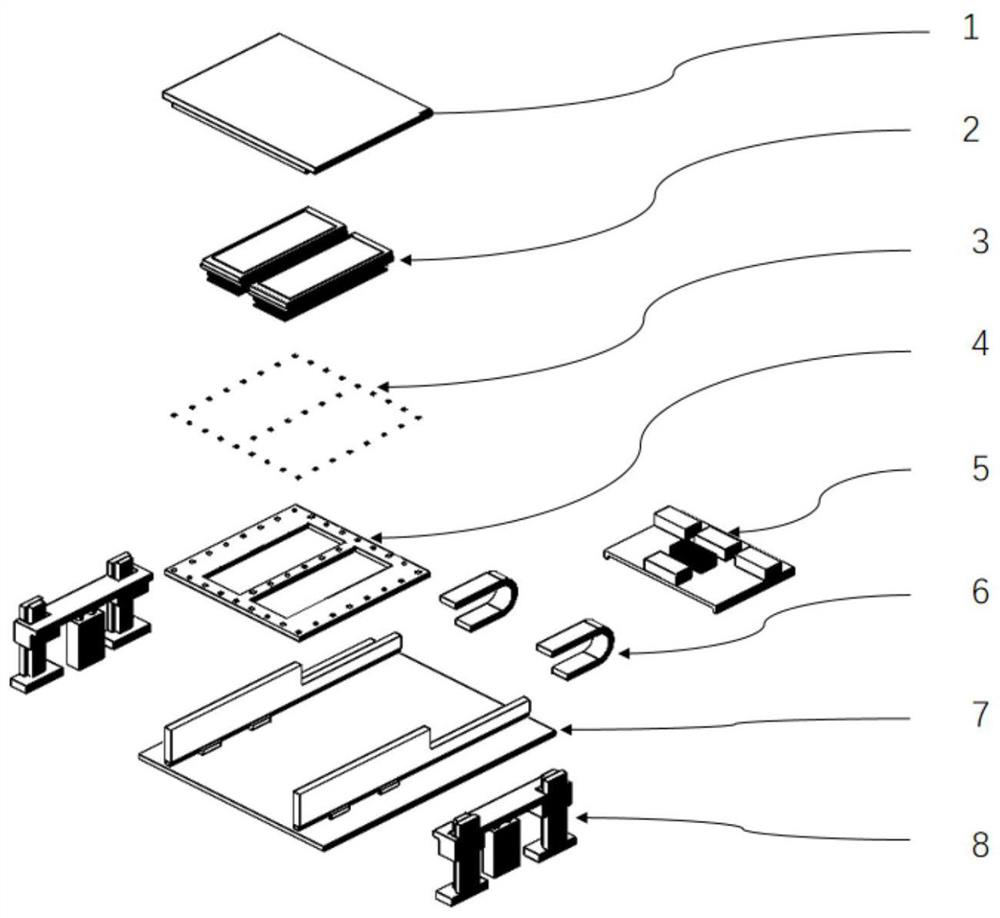

[0083] Example 1: Dynamic adjustment device for elastic deformation of frame plate in FCT testing machine

[0084] Such as Figure 1-2 As shown, the present invention provides a dynamic adjustment device for the elastic deformation of the middle frame plate of an FCT testing machine, which mainly consists of the following 8 parts, including: a pressing plate module 1, a needle carrier module 2, a strain gauge 3, and a middle frame Plate module 4, dynamic control module 5, tank chain 6, entry and exit drive module 7 and up and down drive module 8.

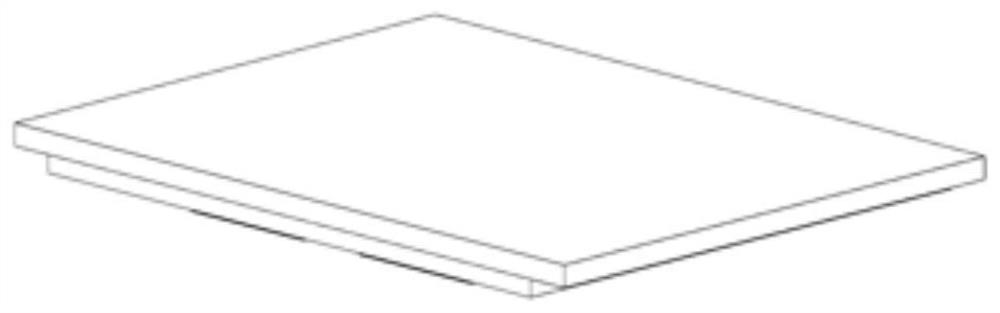

[0085] Such as Figure 3-4 As shown, the pressure plate module provided by the present invention is used to transmit the force of the upper and lower drive modules to the tested PCB and the carrier board, reasonably suppress the stroke of the tested PCB, so that the needle plate probe contacts the PCB test point, and realizes the signal Interconnection; the platen module is mainly composed of the following five parts, including: d...

Embodiment 2

[0101] Example 2: Dynamic adjustment method for elastic deformation of frame plate in FCT testing machine

[0102] Such as Figure 17 As shown, this embodiment belongs to the real-time dynamic adjustment closed-loop system. It can realize real-time monitoring of the deformation of the middle frame plate, dynamically adjust the air pressure of the pressure regulating valve, prevent the transitional deformation of the middle frame plate, control its reasonable deformation, and prevent the stroke of the probe from being reduced due to the transitional deformation of the middle frame plate. Poor contact has a positive effect on improving the test stability of the tested PCB.

[0103] The dynamic adjustment method of the elastic deformation of the frame plate in the FCT testing machine (that is, the closed-loop control theory algorithm) is as follows:

[0104] Step 1 Measurement and solution process (stress analysis module):

[0105] First, the strain gauges will be pasted equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com