Four-wheel-drive two-claw type vehicle carrying robot

A four-wheel drive, two-claw type, vehicle handling technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of large space occupation, high manufacturing cost, redundant structure, etc., and achieve the goal of reducing occupied space, reducing production costs, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

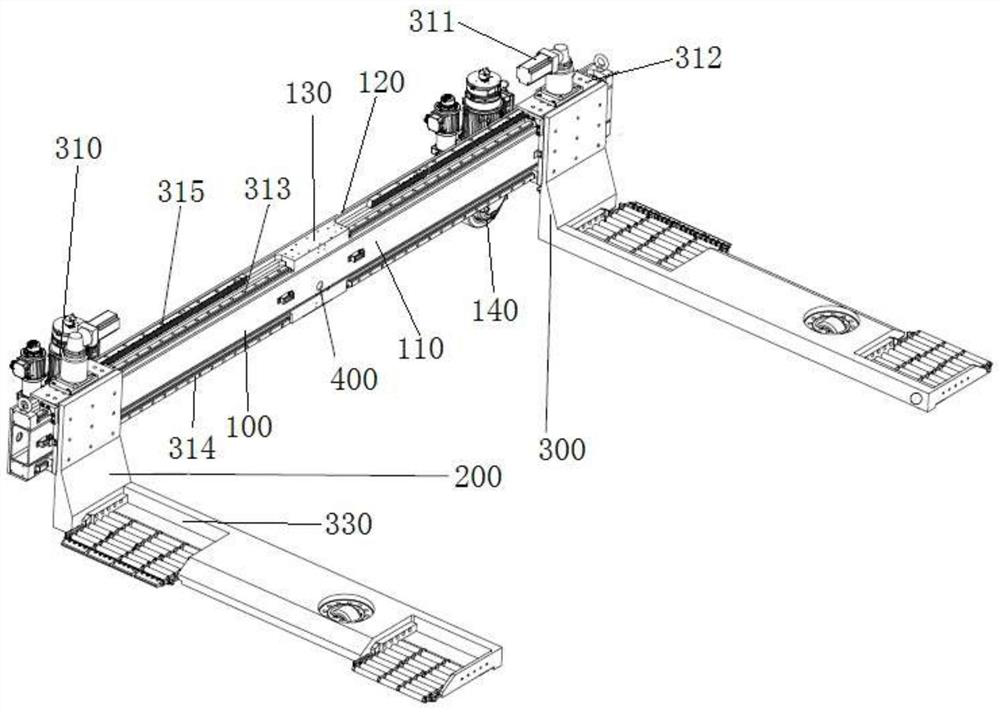

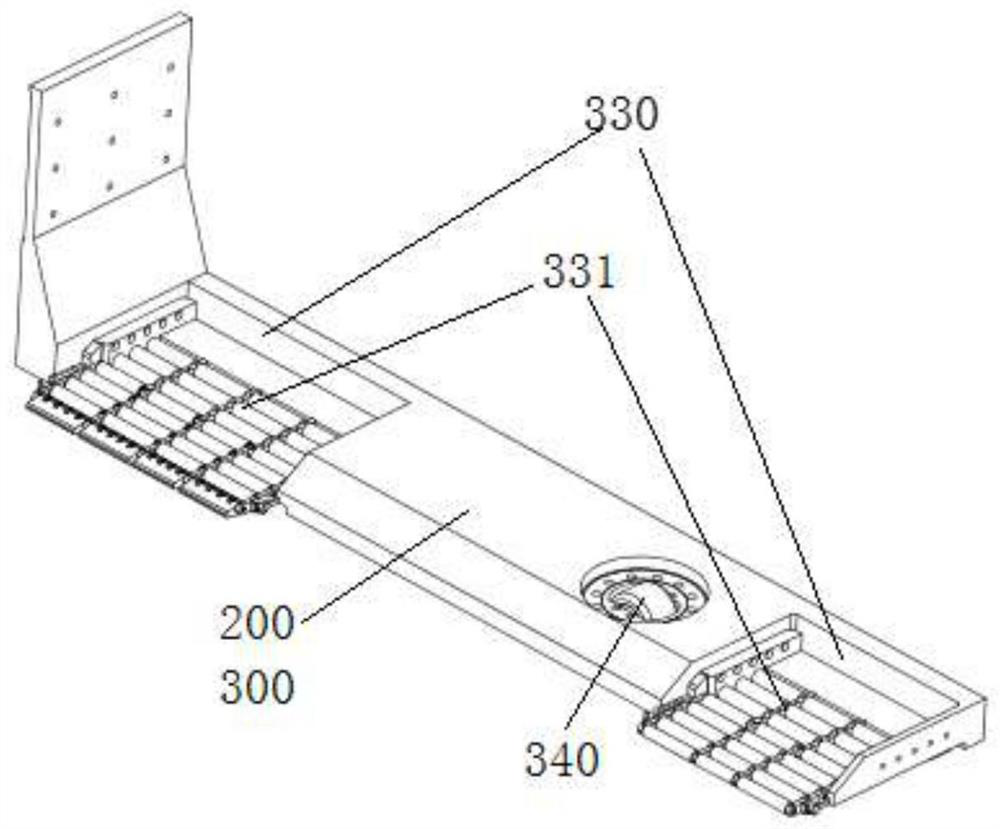

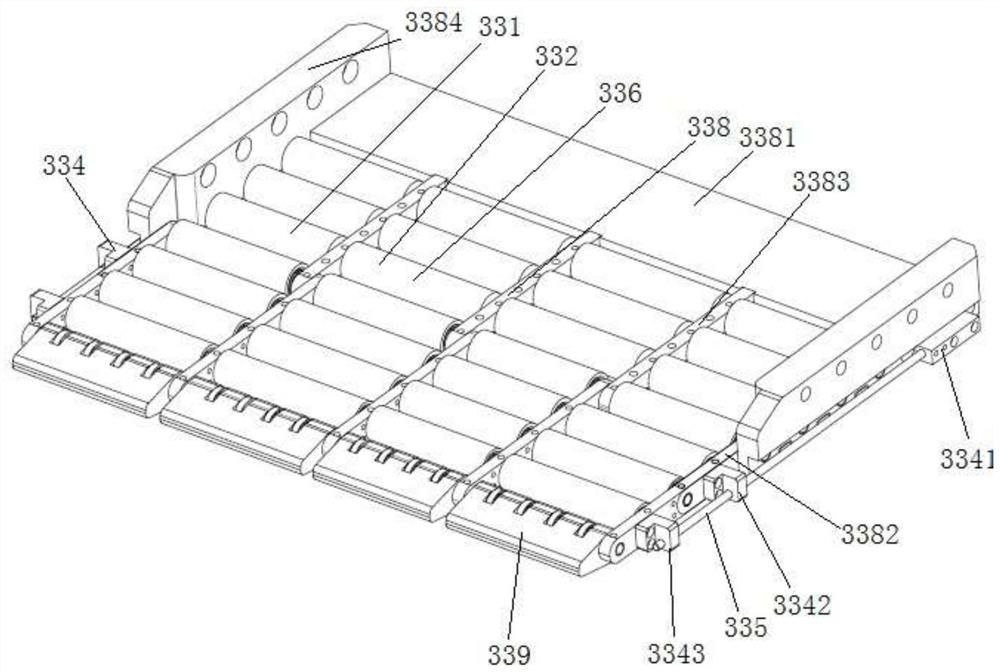

[0038] Such as Figure 1-6 As shown, this embodiment relates to a four-wheel-drive two-claw vehicle handling robot, such as figure 1 As shown, the robot includes: a vehicle frame 100, the vehicle frame 100 is a straight structure; an active walking device 140, the active walking device 140 is installed on the two ends of the vehicle frame 100, and is used to drive the vehicle frame 100 to move A left yoke 200 and a right yoke 300 with the same symmetrical structure, the left yoke 200 and the right yoke 300 are installed on the same side of the vehicle frame 100 respectively, the distance between the two is adjustable, so that the wheel can be inserted The wheels are lifted off the ground by moving towards or away from the ground; a universal wheel 340, which is installed on the left yoke 200 and the right yoke 300, to meet the driving requirements of the vehicle handling robot.

[0039] A photoelectric sensor 400 is provided in the middle of the vehicle frame 100 on the same ...

Embodiment 2

[0049] Such as Figure 2-7 As shown, this embodiment relates to a four-wheel-drive two-claw vehicle handling robot, such as Figure 6 As shown, the robot includes: a vehicle frame 100, the vehicle frame 100 is a straight structure; an active walking device 140, the active walking device 140 is installed on the two ends of the vehicle frame 100, and is used to drive the vehicle frame 100 to move A left yoke 200 and a right yoke 300 with the same symmetrical structure, the left yoke 200 and the right yoke 300 are installed on the same side of the vehicle frame 100 respectively, the distance between the two is adjustable, so that the wheel can be inserted The wheels are lifted off the ground by moving towards or away from the ground; a universal wheel 340, which is installed on the left yoke 200 and the right yoke 300, to meet the driving requirements of the vehicle handling robot.

[0050] A photoelectric sensor 400 is provided in the middle of the vehicle frame 100 on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com