Wind power blade web layering structure and layering method thereof

A wind power blade and layering technology, which is applied to wind power generation, wind turbines that are consistent with the wind direction, wind turbines, etc., can solve problems such as low production efficiency and long time consumption, achieve easy operation, improve production efficiency, and shorten mold occupation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

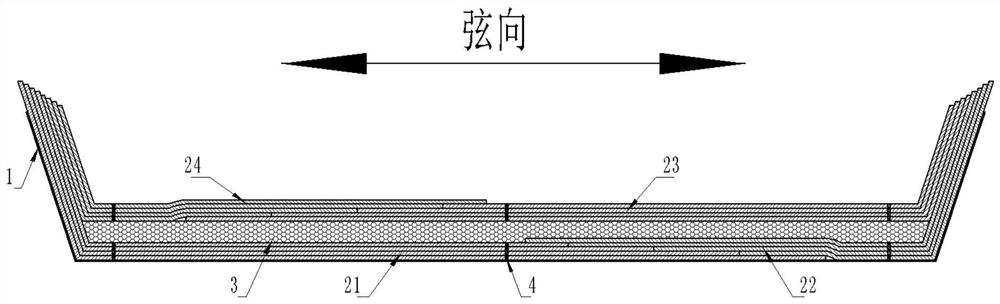

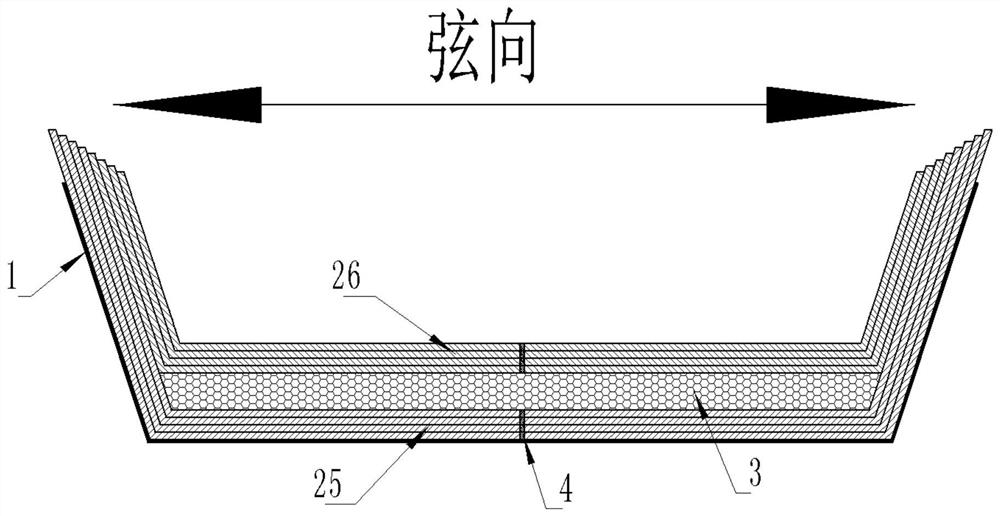

[0029] In order to better understand the purpose, structure and function of the present invention, a wind turbine blade web lay-up structure and lay-up method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 1 to Figure 4 As shown, it is shown as a wind power blade web lay-up structure and lay-up method of the present invention, especially for large-scale wind power blade web laying, in the blade web mold 1 (leading edge web mold and trailing edge web mold Die) lay glass fiber cloth 2, core material 3 and various auxiliary materials. In the present invention, multiple layers of sewn glass fiber cloth 2 and core material 3 are laid in the web mold 1, and two-way simultaneous laying is carried out in the axial direction, so as to improve the laying speed and quality.

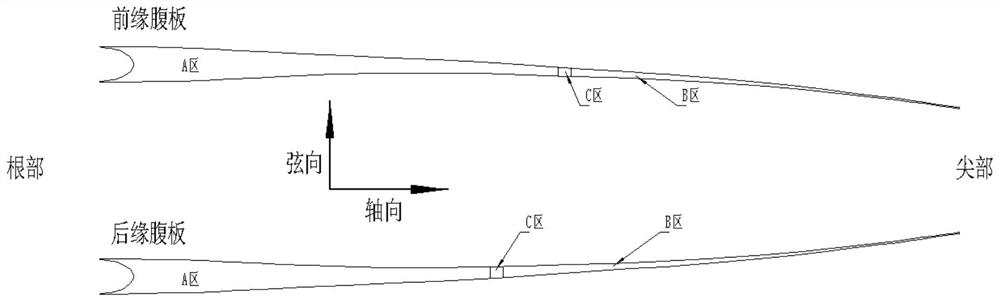

[0031] further, such as figure 1 As shown, the laminated structure of the blade web (leading edge web and trailing edge w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com